Improved automatic polishing device

An automatic polishing and improved technology, applied in grinding/polishing equipment, mechanical equipment, metal processing equipment, etc., can solve the problems of uneven surface of the workpiece, low polishing efficiency, low polishing work efficiency, etc., to achieve convenient operation and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

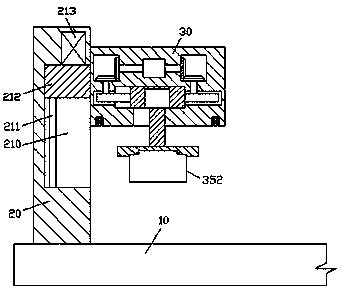

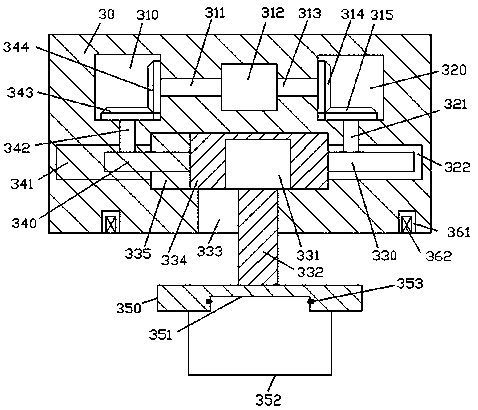

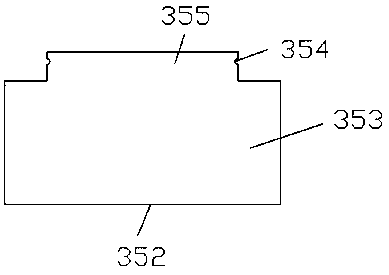

[0013] Such as Figure 1-Figure 3 As shown, an improved automatic polishing equipment of the present invention includes a support frame body 20 fixedly installed on the upper end surface of one side of the working platform 10 and a polishing machine body movably mounted on the support frame body 20 through a lifting drive device 30, the left and right sides of the inner wall of the polishing body 30 are provided with a first transmission chamber 310 and a second transmission chamber 320, and the inner wall of the polishing body 30 between the first transmission chamber 310 and the second transmission chamber 320 A first motor 312 is fixedly installed in the middle, and a sliding cavity 335 is arranged in the inner wall body of the polishing body 30 on the lower side of the first motor 312, and a sliding seat 334 is slidably fitted in the sliding cavity 335. The left and right sides of the sliding cavity 335 are respectively connected with a first rotating chamber 341 and a sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap