Push-type clamping table

A clamping table, push-type technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of incomplete clamping mechanism, reduced structure space, etc., and achieve the effect of fast action, reduced structure, and small action range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

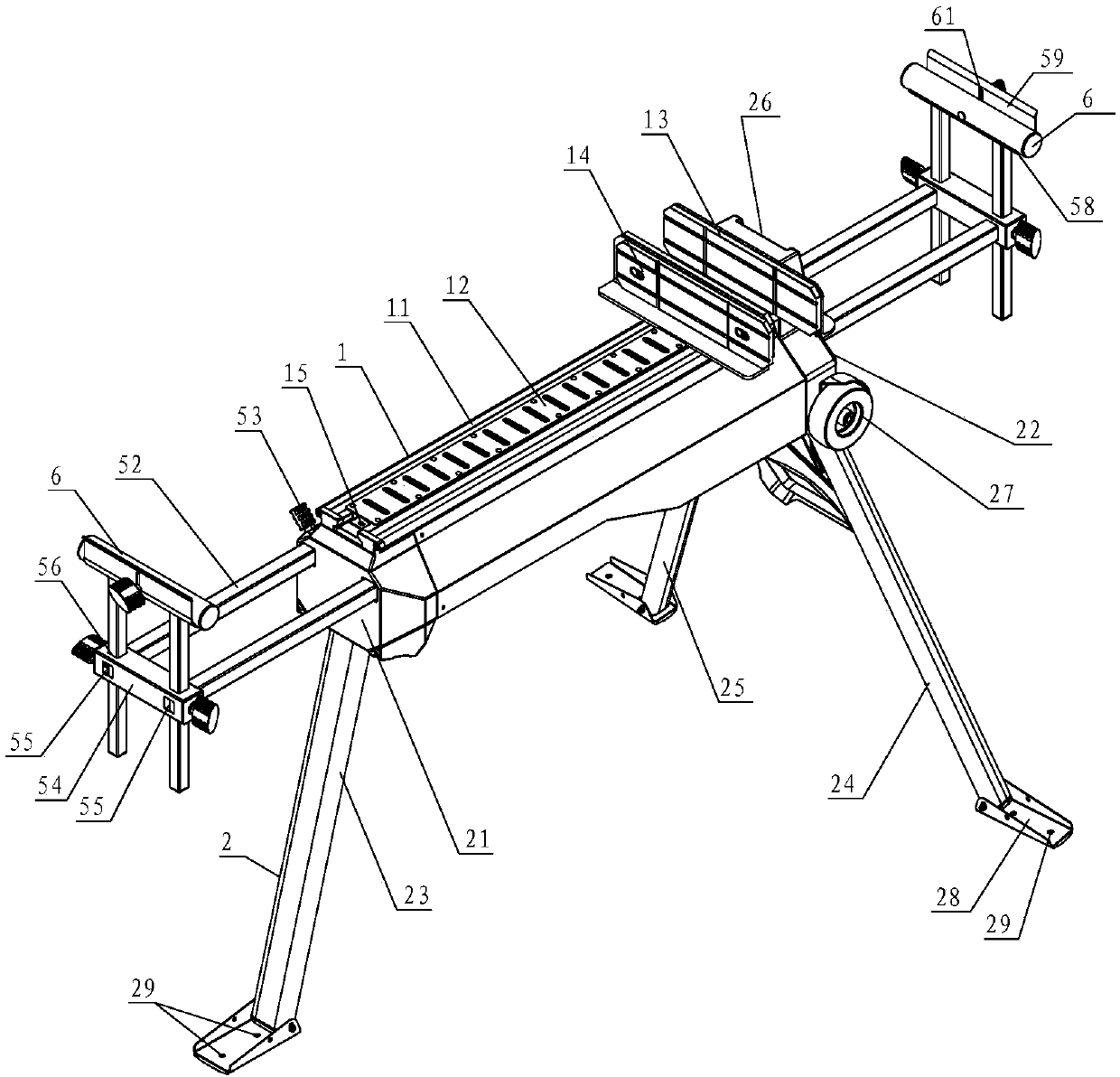

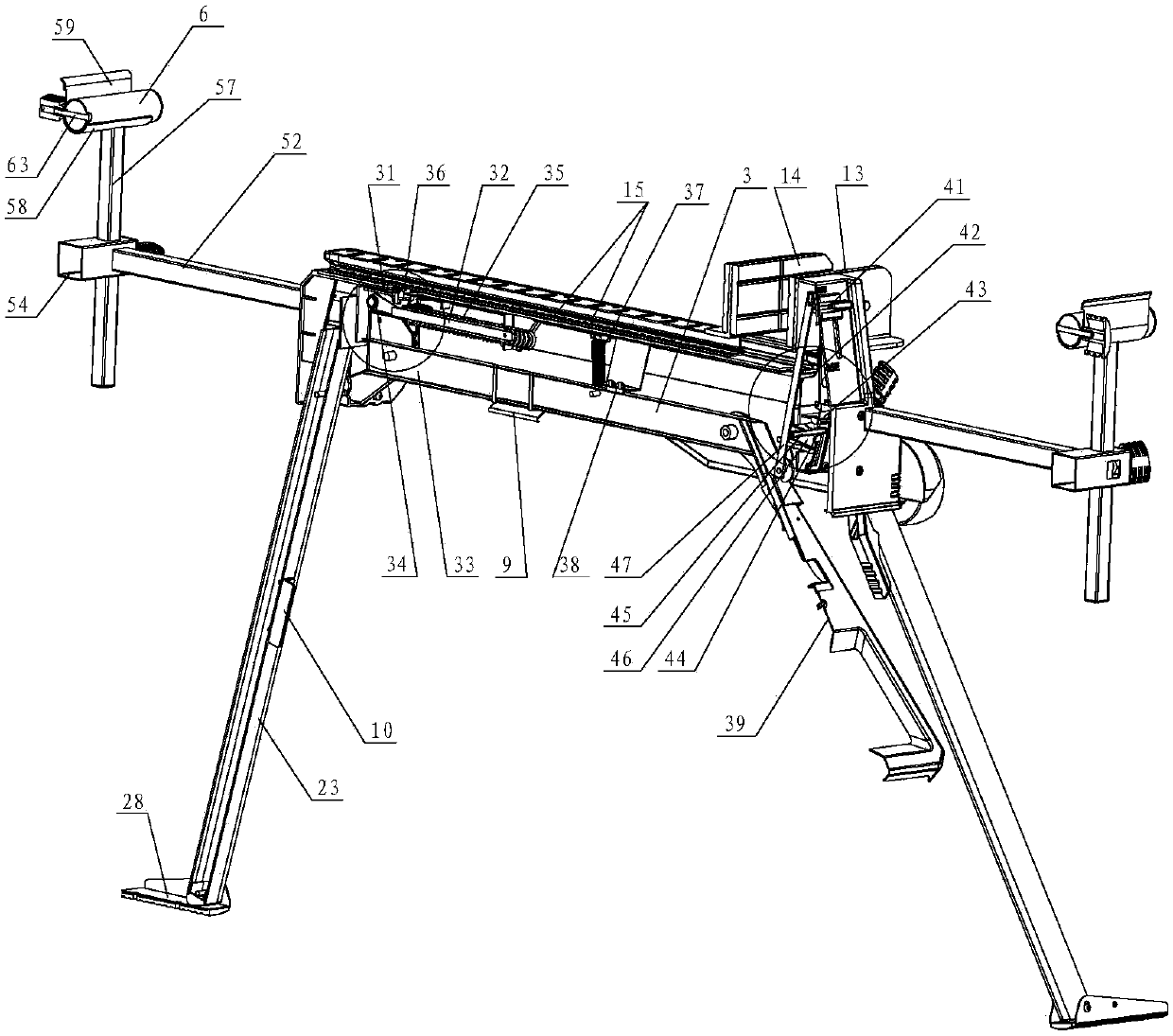

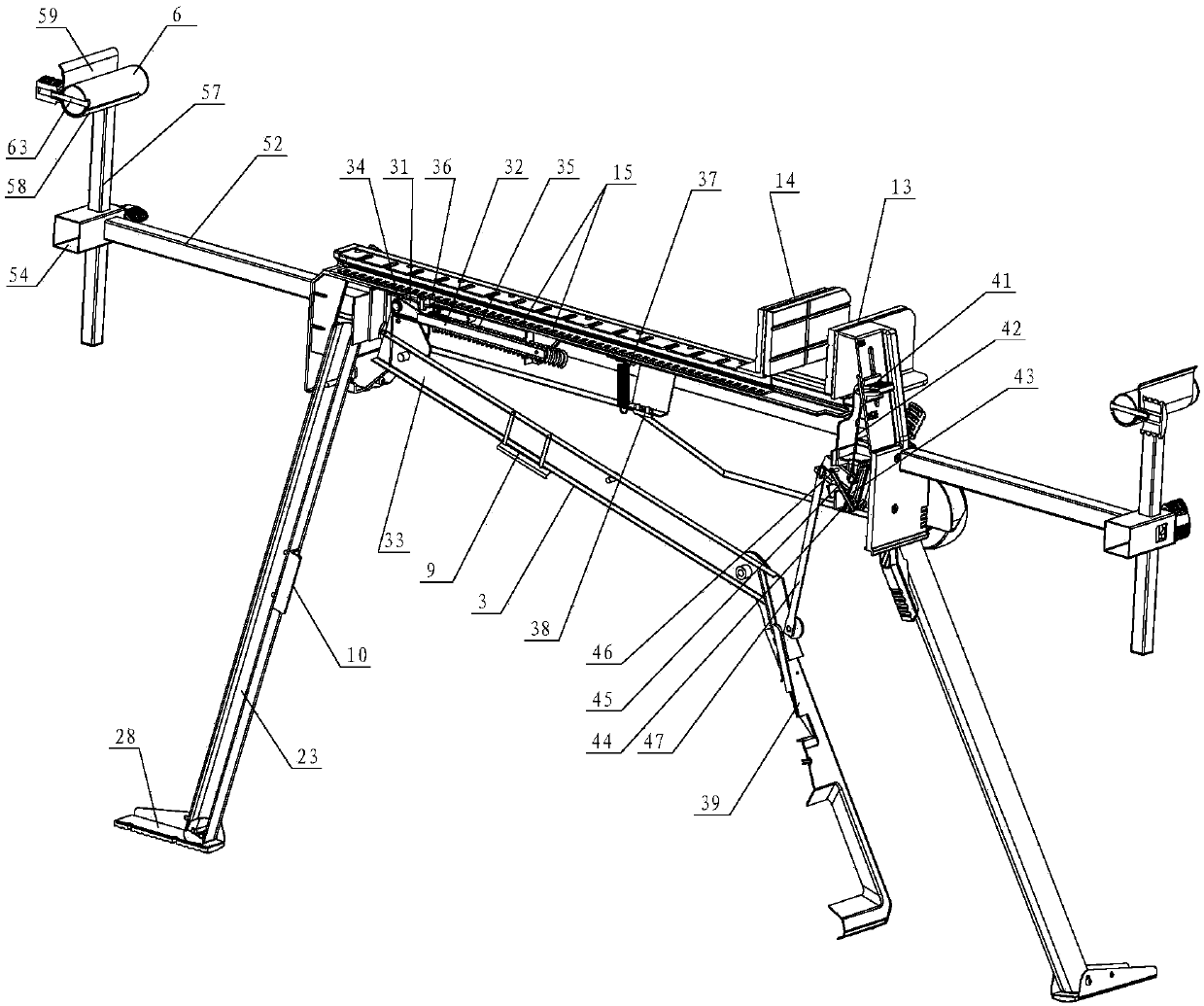

[0041] Such as figure 1 , 2 , 3, a push-type clamping table, including a table assembly 1, a tripod assembly 2 for support, a driving device 3 for driving the translation of the table, and a switch device 4 for locking the driving device.

[0042] The table assembly consists of a table base 11 , a table slide 12 , a static splint 13 and a dynamic splint 14 .

[0043] Wherein, the table base 11 is a strip-shaped profile, and there is a groove track in the center of the profile. From the cross section of the table base 11, the groove is an upper opening, and the groove is narrow at the top and wide at the bottom. An inverted T shape, or an inverted isosceles trapezoid combined with a square, etc.; one end of the table base 11 is provided with a static splint 13 .

[0044] The table slide 12 is a slat-shaped profile, the upper layer is a straight slat, and the lower part of the slat is set as a downward raised part, and the structure of the raised part is matched with the groov...

Embodiment 2

[0064] Such as Figure 7 As shown, compared with Embodiment 1, the difference of this embodiment is that there are no extension tubes, roller brackets and rollers at both ends of the table, and the clamping table is only used as a clamping table without the function of a miter saw support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com