Processing device for roll paper

A processing device and roll paper technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of difficult extraction of the shaft, reduce processing procedures, improve rewinding effect, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

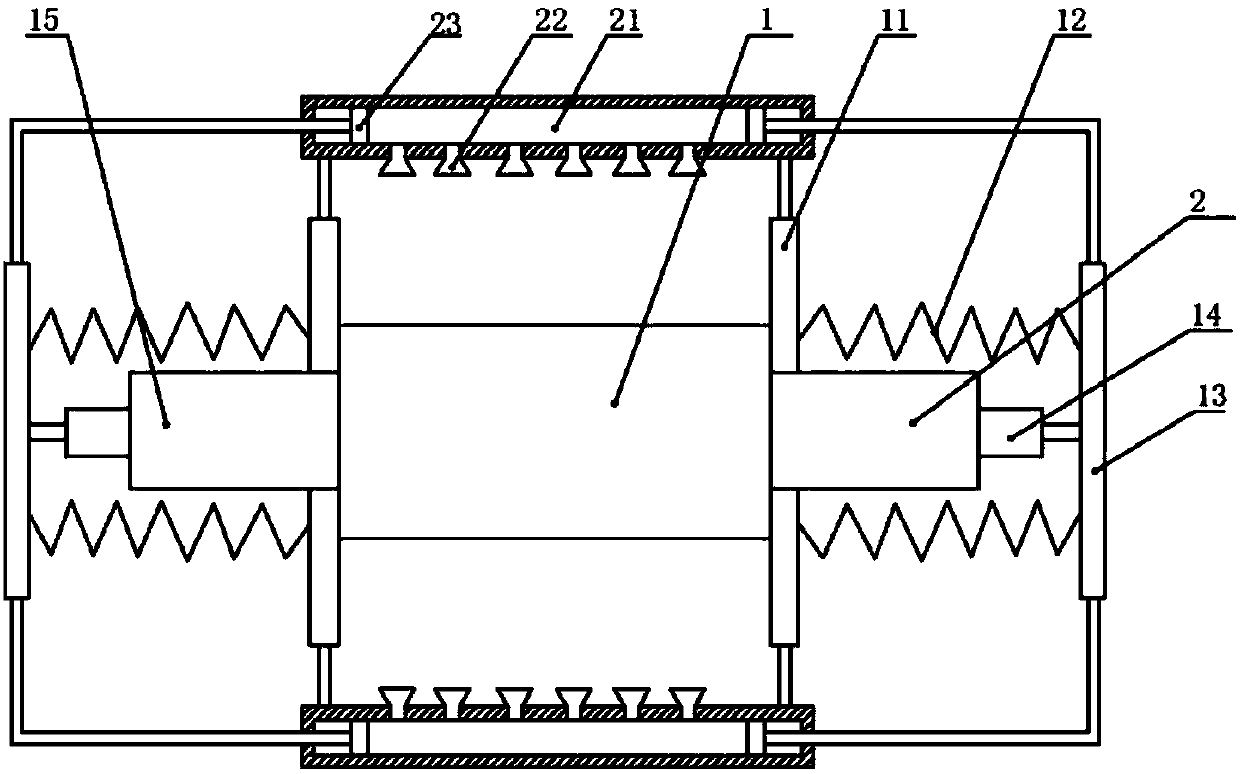

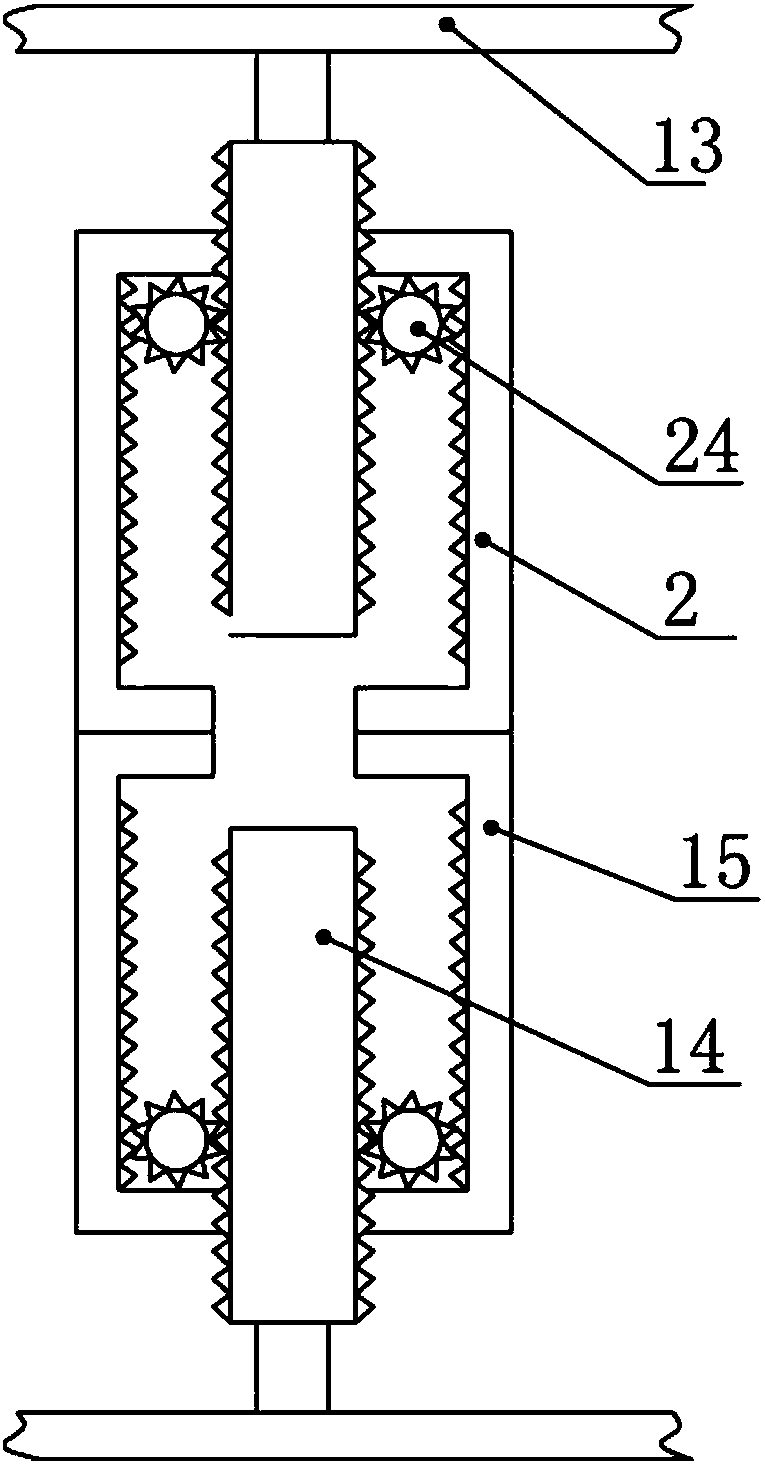

[0022] The reference signs in the drawings of the description include: paper tube 1, retaining ring 11, spring 12, support rod 13, push column 14, first rotating shaft 15, second rotating shaft 2, fragrance storage tube 21, spray head 22, piston 23, gear 24.

[0023] Such as figure 1 As shown, a processing device for roll paper in the present invention includes a paper tube 1, a first rotating shaft 15 and a second rotating shaft 2 are inserted in the paper tube 1, and the first rotating shaft 15 and the second rotating shaft 2 are arranged on the paper tube 1. The inner middle parts are offset, and the first rotating shaft 15 and the second rotating shaft 2 have the same length and coincident axes. Such as figure 2 As shown, the inside of the first rotating shaft 15 and the second rotating shaft 2 are cavities, and a push column 14 is installed in the cavity. Drive teeth, gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com