Winder for tempered glass packaging film

A technology of tempered glass and packaging film, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing. It can solve the problems of high cost and low collection efficiency of car window packaging scraps, and achieve load reduction, simple structure, and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

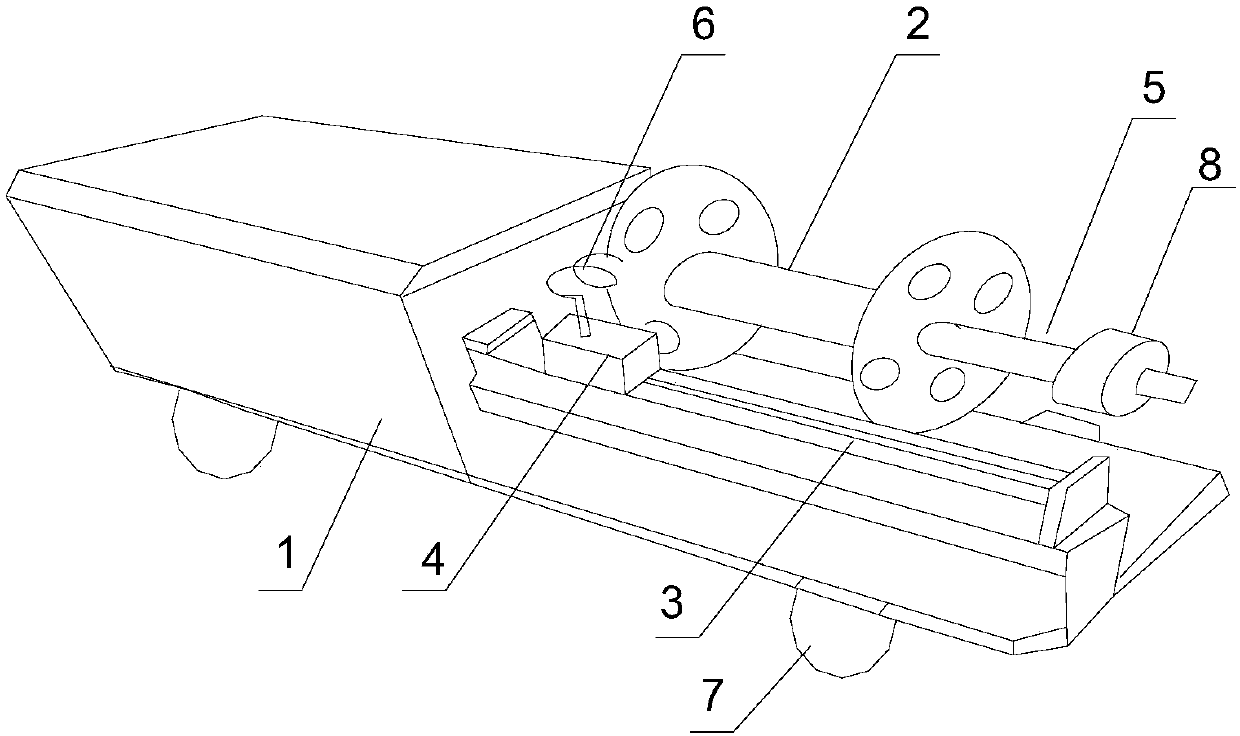

[0021] Such as figure 1 As shown, the present embodiment includes a frame 1, a collection tube 2, a chute 3 and a traction block 4, the frame 1 is provided with a motor, and the rotating shaft 5 of the motor is connected with the collection tube 2, and the traction block 4 is provided with a spring-shaped guide ring 6, and the bottom of the frame 1 is also provided with a plurality of universal wheels 7; during the packaging process of automobile glass, the discarded leftovers after cutting pass through the guide ring 6 on the traction block 4 and The collection cylinder 2 is connected. Driven by the servo motor, the collection cylinder 2 rotates with the rotating shaft 5 and starts to collect corner materials. The collection cylinder 2 and the rotating shaft 5 are detachably connected. When the collected film waste is full, the rotating shaft 5 The locking bolt on the upper part will replace the collection tube 2 to process the collected waste; when a certain amount of waste ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap