Double-locked oil cylinder

A double locking, oil cylinder technology, applied in the field of oil cylinders and hydraulics, can solve the problem of insufficient safety, and achieve the effect of high reliability and safety, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

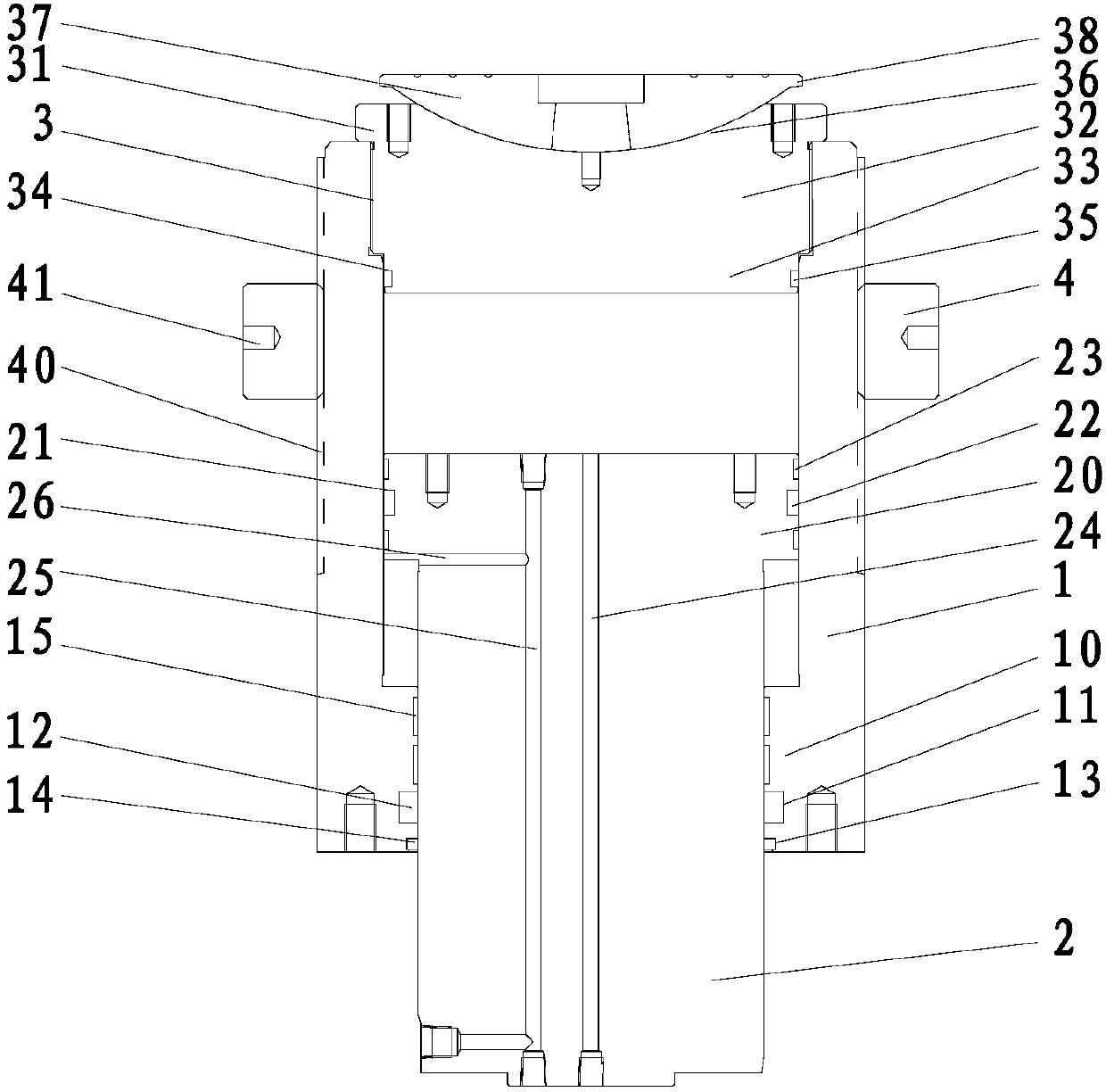

[0016] refer to figure 1 , a double-lock oil cylinder of the present invention, comprising a cylinder 1, a piston 2, a lock nut 4, and a cylinder top cover 3, the cylinder 1 is vertically arranged, and a cylinder top 3 is installed on the upper end of the cylinder 1, and the cylinder 1 A sealing snap ring 10 is provided on the inner wall of the lower end, and a plurality of first sealing grooves 11 and first guide grooves 15 are arranged on the sealing snap ring 10, and a first sealing ring 12 is embedded in the first sealing groove 11, and the piston 2 Extending into the cylinder 1, the top of the piston 2 is a sealing head 20 that matches the inner wall of the cylinder 1, and the outer wall of the sealing head 20 is provided with a number of second sealing grooves 21 and second guide grooves 23, and inside the second sealing groove 21 Embedded with a second seal ring 22, the piston 2 is provided with a top outlet oil hole 24 and a return oil hole 25, the upper opening ends o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap