Fiber optic socket module and integrated socket using same

A technology of optical fiber socket and socket module, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problem of limited signal transmission capacity of a single optical fiber connector, and achieve the effect of improving signal transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

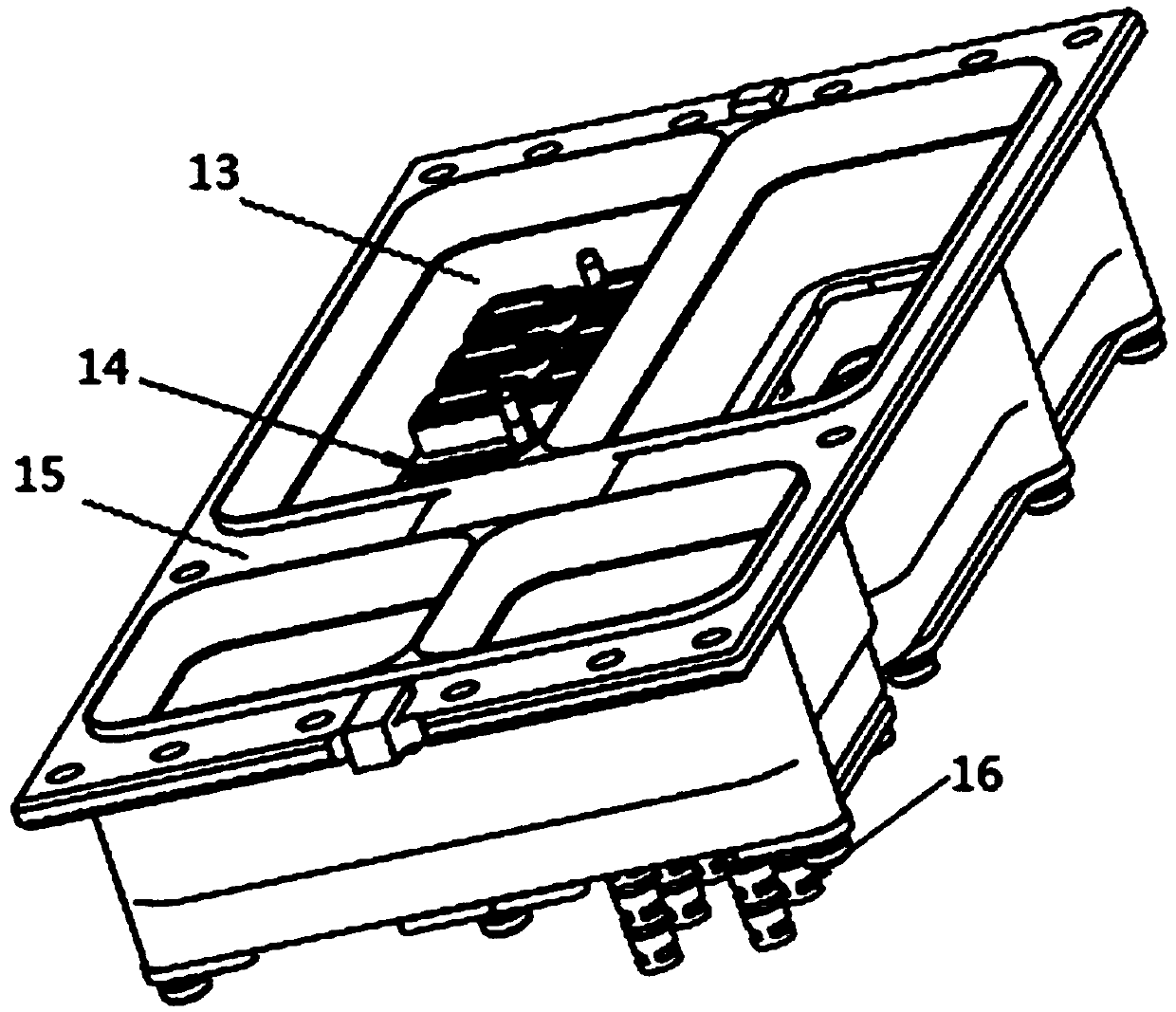

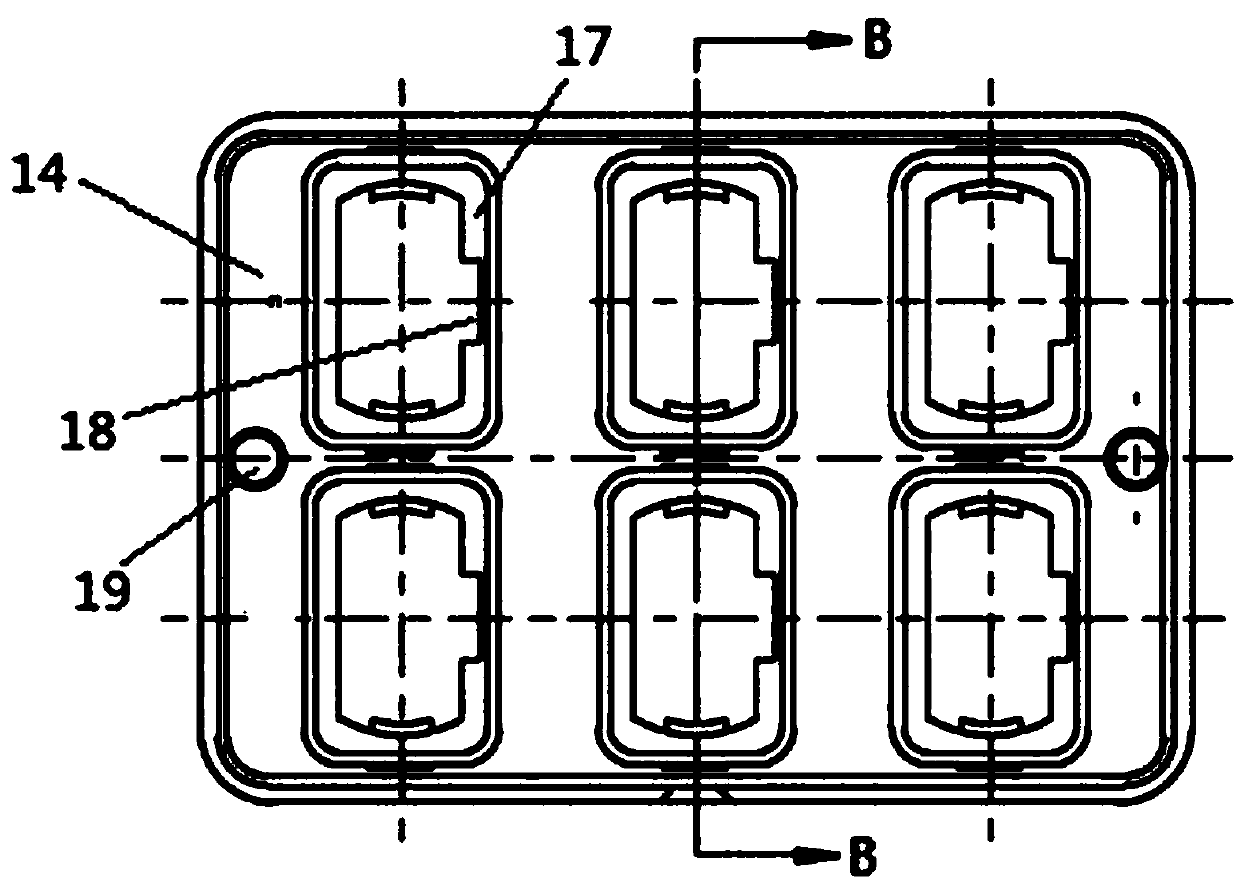

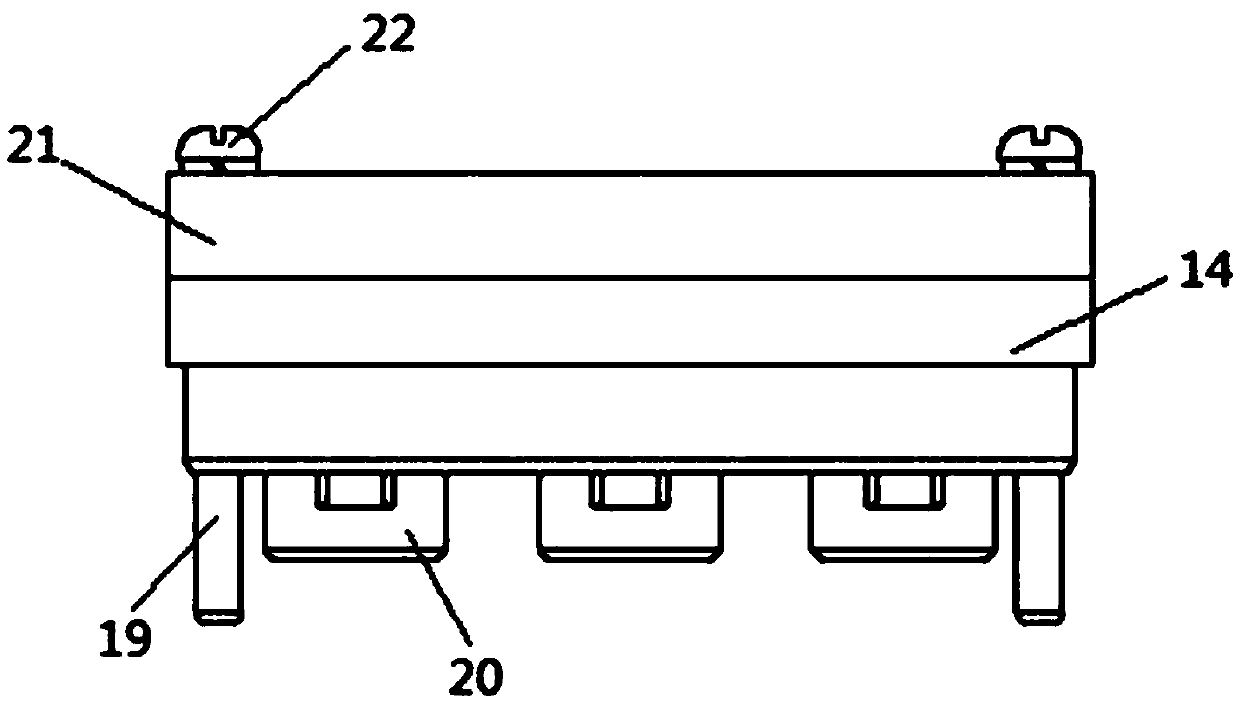

[0031] Examples of integrated sockets are Figure 1-10 As shown: it includes an integrated socket housing 15, on which an optical fiber socket module 14 is arranged. Insulator mounting holes, each insulator mounting hole is provided with a socket insulator 17 through an insulator fixing structure, the outer periphery of the socket insulator is provided with an insulator step 10 facing forward, and the insulator fixing structure includes an insulator step that is arranged on the wall of the insulator mounting hole. Blocking fit to limit the installation steps of the forward movement limit of the socket insulator, the insulator fixing structure also includes a socket pressure plate fixed on the rear end of the socket module shell and mated with the rear end of each socket insulator to limit the backward movement limit of each socket insulator 21. The socket pressing plate 21 is fixed to the rear end of the socket module shell through the socket screw 22. There is a movable gap b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com