Spark plug thread detection device and method

A technology for detection devices and spark plugs, applied to spark plugs, electrical components, circuits, etc., can solve problems such as low efficiency, cumbersome steps, and inability to meet mass production inspections in factories, achieve high efficiency, simple operation, and ensure safe and high-quality production Effect

Active Publication Date: 2019-08-16

桐城市建设投资发展有限责任公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, the more advanced thread measurement method in the world is the thread indicator measurement method. Although this method is very accurate for the detection of various thread parameters, the steps are cumbersome and the efficiency is low, which cannot meet the requirements of mass production testing in factories.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

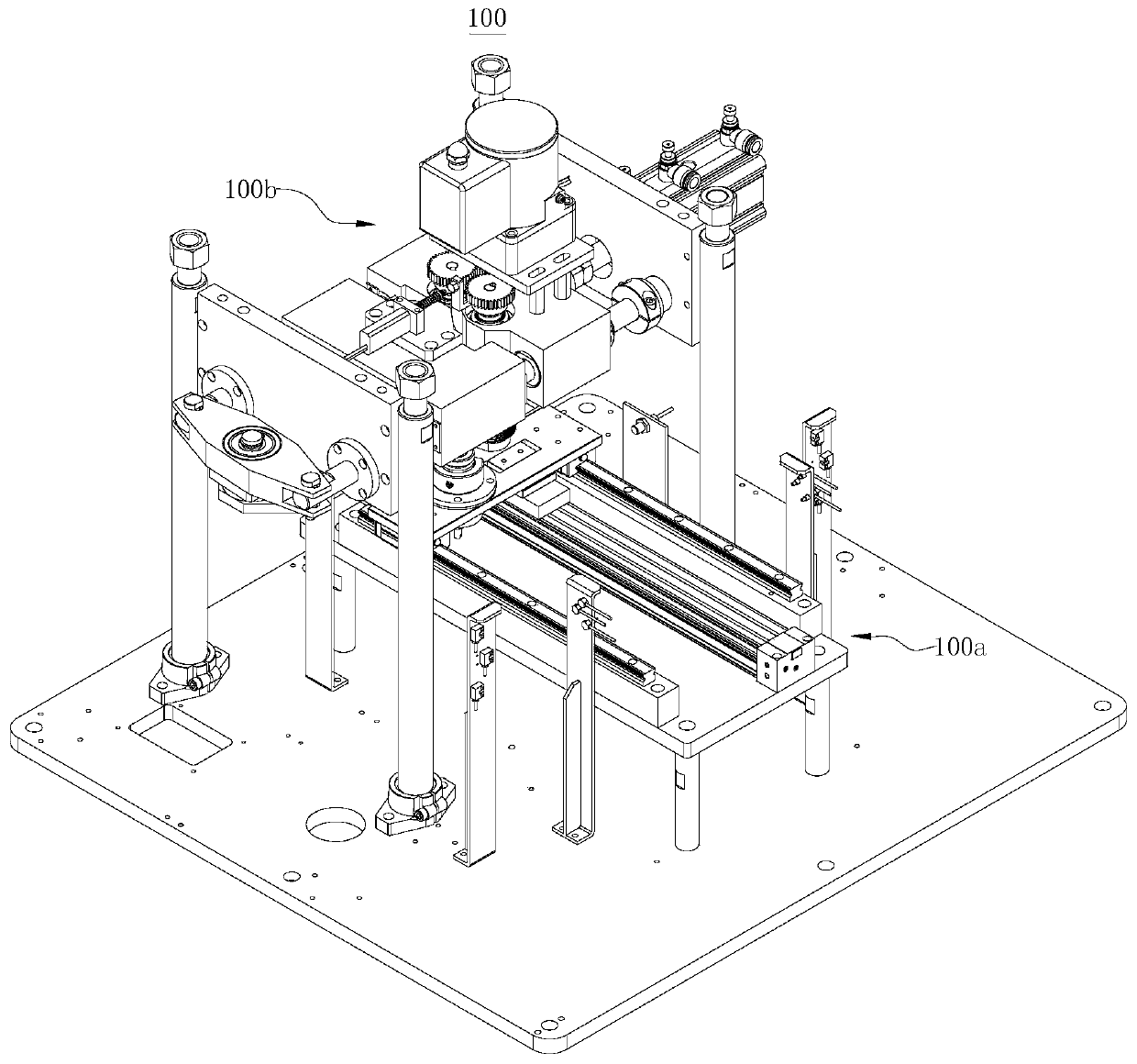

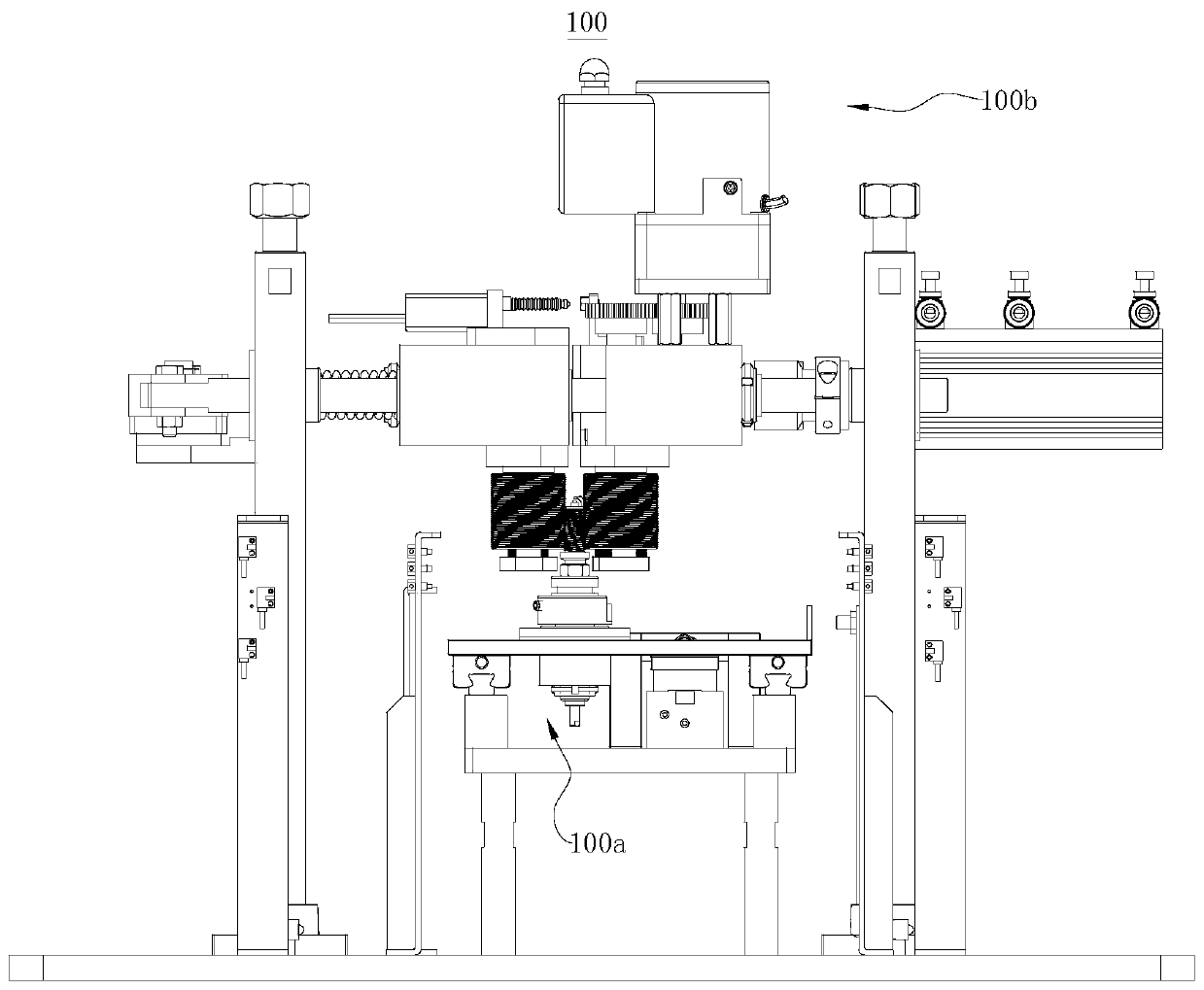

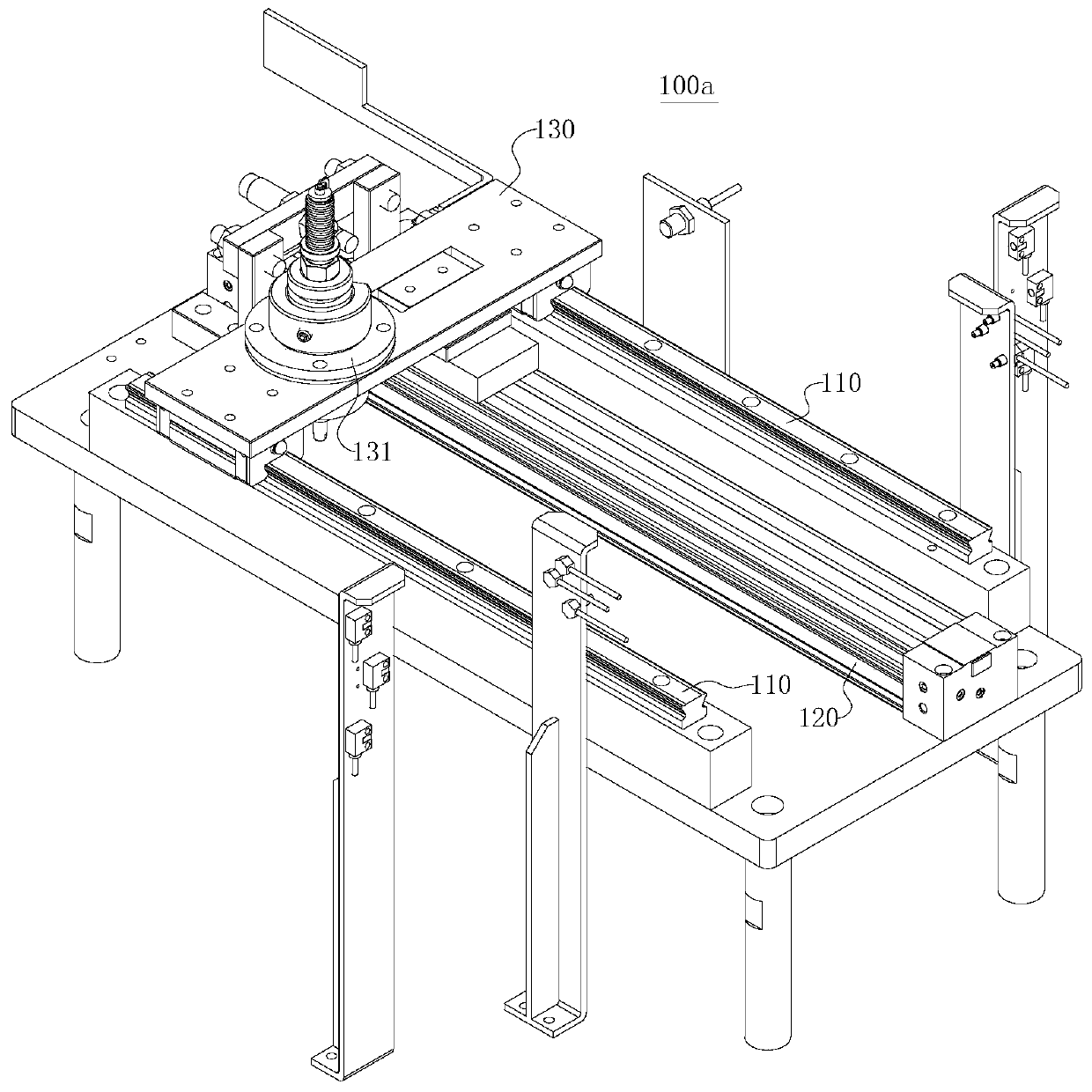

[0045] Please also refer to figure 1 and figure 2 , the present embodiment provides a spark plug thread detection device 100, which includes a spark plug input part 100a and a thread detection part 100b.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A spark plug thread detection device and method belong to the technical field of spark plug detection. The spark plug thread detection device includes a workbench which is used for fixing a spark plugand exposing the installation thread of the spark plug, a first detection part which includes first clamping parts having threaded parts matching the installation thread, and a detection component which is used for detecting the displacement of the first clamping parts from a preset position to a detection position and judging whether the effective diameter of the spark plug is qualified or not.The method includes the following steps: a spark plug is fixed on the workbench, and the installation thread of the spark plug is exposed; the first clamping parts having threaded parts matching the installation thread are moved from a preset position to a detection position to engage with the installation thread; and the detection component detects the displacement of the first clamping parts andjudges whether the effective diameter of the spark plug is qualified or not. The steps of thread detection are simple, and the efficiency of detection is high. The threaded parts are rotationally arranged and can be used to correct the tiny scratch of the teeth of the installation thread, which is beneficial to ensuring the safe and high-quality production of spark plugs.

Description

technical field [0001] The invention relates to the technical field of spark plug detection, in particular to a spark plug thread detection device and method. Background technique [0002] The engine is the heart of the locomotive, and the pacing part of the entire heart is the spark plug of the locomotive, which is the premise and basis for ensuring the efficiency and quality of the engine. One of the important structures of the spark plug is its installation thread, which is installed on the top of the combustion chamber of the internal combustion engine to seal the cylinder spark plug hole to maintain the pressure in the cylinder. However, the working pressure in the cylinder combustion chamber is about 45 times the atmospheric pressure, and the spark plug needs to Often in the high-temperature combustion chamber, at the same time it must maintain extremely high airtightness, so the installation thread of the spark plug is particularly important. [0003] The matching ac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01T13/58

CPCH01T13/58

Inventor 张俊刘海生李冬平刘亚丽付正飞张海燕陈国华

Owner 桐城市建设投资发展有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com