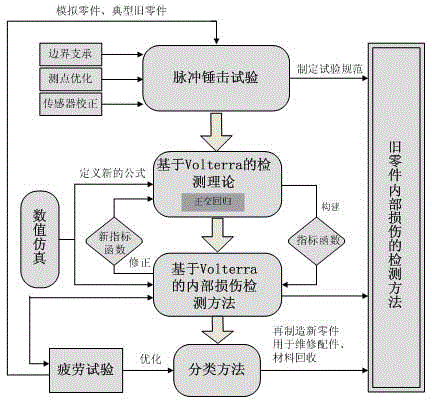

Internal damage detection method for old mechanical part based on Volterra series

A technology for damage detection and mechanical parts, applied in the direction of measuring devices, testing material strength by applying repetitive force/pulsation force, instruments, etc., to achieve the effect of reliable quality, simple operation and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Select the old crankshaft parts of No. 45 steel as the test piece. The first step: analyze the fatigue nucleation, micro-crack formation, and macro-cracks of the test piece in the tensile test through the fatigue test equipment combined with the fracture scanning electron microscope observation and X-ray energy spectrum. Acoustic emission characteristics of the four stages of expansion and final fracture, combined with fracture mechanics to analyze the mechanism of the four stages, and obtain the simulated part specimens in the four stages; then use the pulse hammer to excite the simulated part specimens to make them reach Resonance or critical resonance, that is, its vibration response reaches a maximum, on which acceleration sensors are preferably arranged at multiple measurement points to pick up its output response under pulse excitation. The second step: by sorting out the response signals of the first step, the Volterra nonlinear model of the system is analyzed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com