A kind of palladium/carbon material catalyst preparation method and application of carbon material in situ immobilized palladium nanoparticles

A carbon material, palladium nanotechnology, applied in the field of catalyst preparation, can solve the problems of high cost, inconsistent with the development concept of green chemical industry, large pollution, etc., and achieve the effect of no reduction in activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

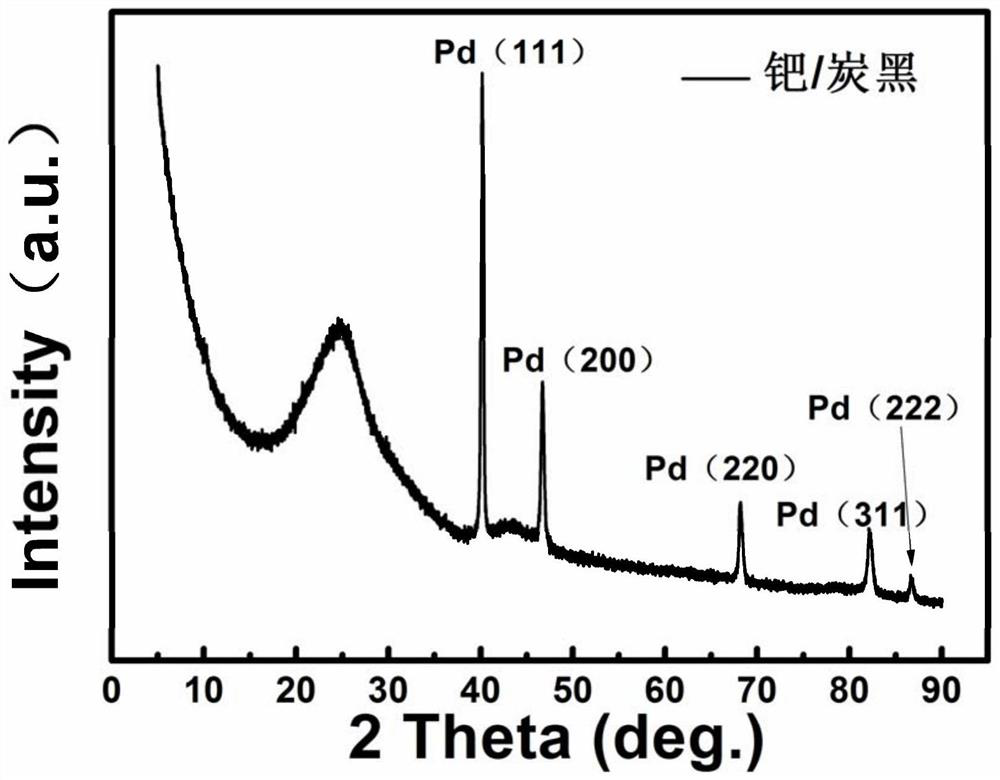

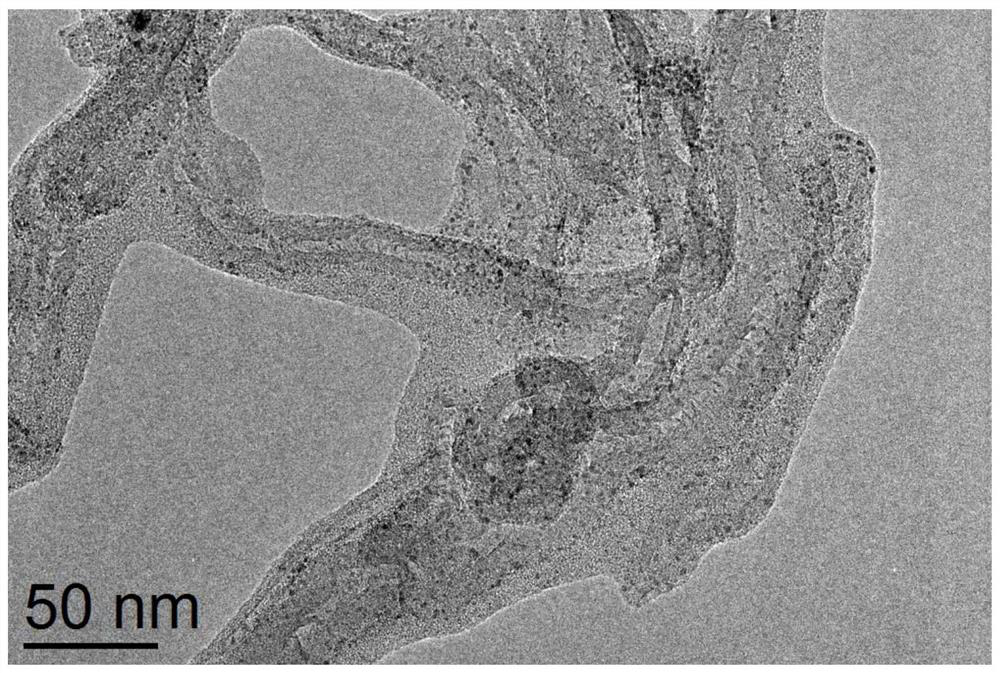

[0021] Step 1, 50ml of acetic acid was added to 500ml of deionized water, stirred for 5min to prepare an aqueous solution of acetic acid; step 2, 50mg of palladium acetate and 500mg of carbon black were placed in the aqueous solution of acetic acid prepared in step 1, and evenly stirred for 60min to prepare To obtain a mixed solution, step 3, place the mixed solution prepared in step 2 for ultrasonic dispersion in an ultrasonic cleaning machine, control the time at 100min, and control the ultrasonic power at 400W, take it out and then stir for 60min; step 4, prepare the mixed solution obtained in step 3 The final dispersion was placed in a rotary evaporator at 90°C and dried for 24 hours to prepare a palladium / carbon black catalyst in which carbon black supported palladium nanoparticles in situ. From the XRD pattern of the sample, such as figure 1 As shown, it can be seen that (111), (200), (220), (311), (222) characteristic diffraction peaks of palladium and (002) graphite br...

Embodiment 2

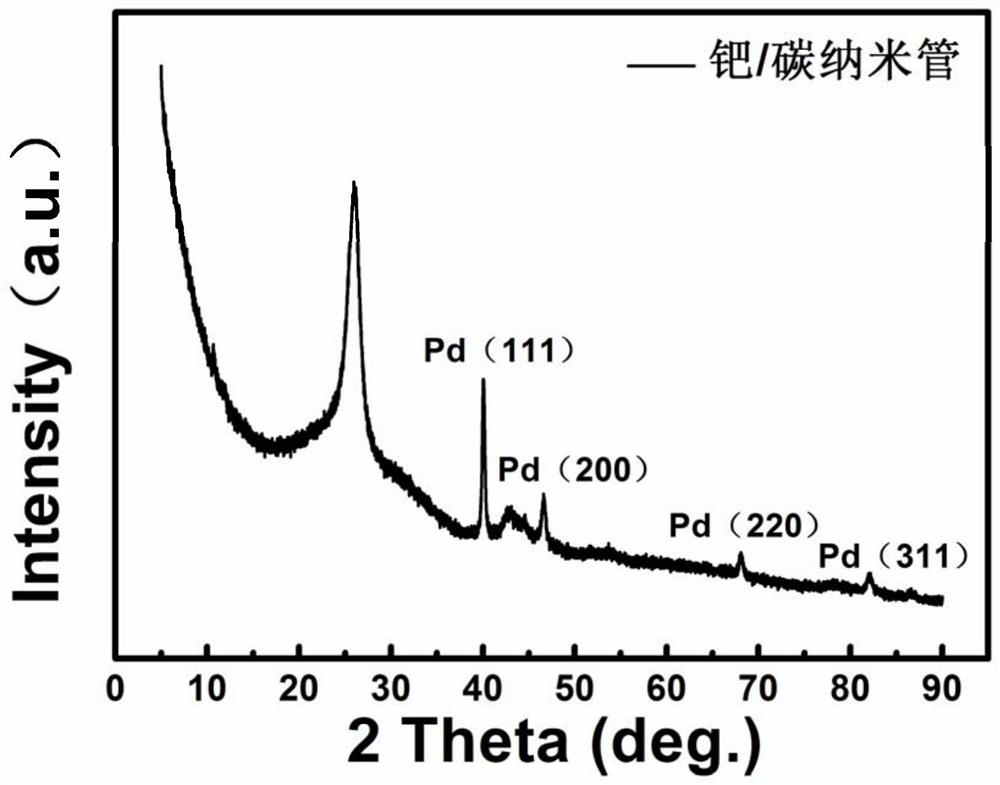

[0023] Step 1, 30ml of acetic acid was added to 350ml of deionized water, stirred for 5min to obtain an aqueous solution of acetic acid; step 2, 40mg of palladium acetate and 300mg of carbon nanotubes were placed in the aqueous solution of acetic acid prepared in step 1, and stirred evenly for 60min, Prepare the mixed solution, step 3, place the mixed solution prepared in step 2 in an ultrasonic cleaner for ultrasonic dispersion, control the time at 100min, control the ultrasonic power at 400W, take it out and then stir for 60min; step 4, prepare the mixed solution in step 3 The mixed dispersion was placed in a rotary evaporator at 60° C. and dried for 36 hours to prepare a palladium / carbon nanotube catalyst in which palladium nanoparticles were immobilized on carbon nanotubes in situ. From the XRD pattern of the sample, such as figure 2 As shown, it can be seen that (111), (200), (220), (311) characteristic diffraction peaks of palladium and (002) characteristic peaks of car...

Embodiment 3

[0025] Step 1, 20ml of acetic acid is added to 200ml of deionized water, stirred for 5min to prepare an aqueous solution of acetic acid; step 2, 20mg of palladium acetate and 150mg of graphene are placed in the aqueous solution of acetic acid prepared in step 1, stirred evenly for 60min to prepare To obtain a mixed solution, step 3, place the mixed solution prepared in step 2 for ultrasonic dispersion in an ultrasonic cleaning machine, control the time at 100min, and control the ultrasonic power at 350W, take it out and then stir for 60min; step 4, prepare the mixed solution obtained in step 3 The final dispersion was placed in a rotary evaporator at 90° C. and dried for 18 hours to prepare a palladium / graphene catalyst in which palladium nanoparticles were immobilized on graphene in situ. From the XRD pattern of the sample, such as Figure 5 As shown, it can be seen that the (111), (200), (220) characteristic diffraction peaks of palladium and the (002) graphite broad peak of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com