A kind of brazing method between wood material and metal

A technology of wooden materials and brazing methods, applied in metal processing equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of reducing the thermal insulation of cryogenic liquid cargo tanks, increasing the processing and installation of wooden materials and cryogenic liquid cargo bulkheads Difficulty and other issues to achieve the effect of reducing energy consumption and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

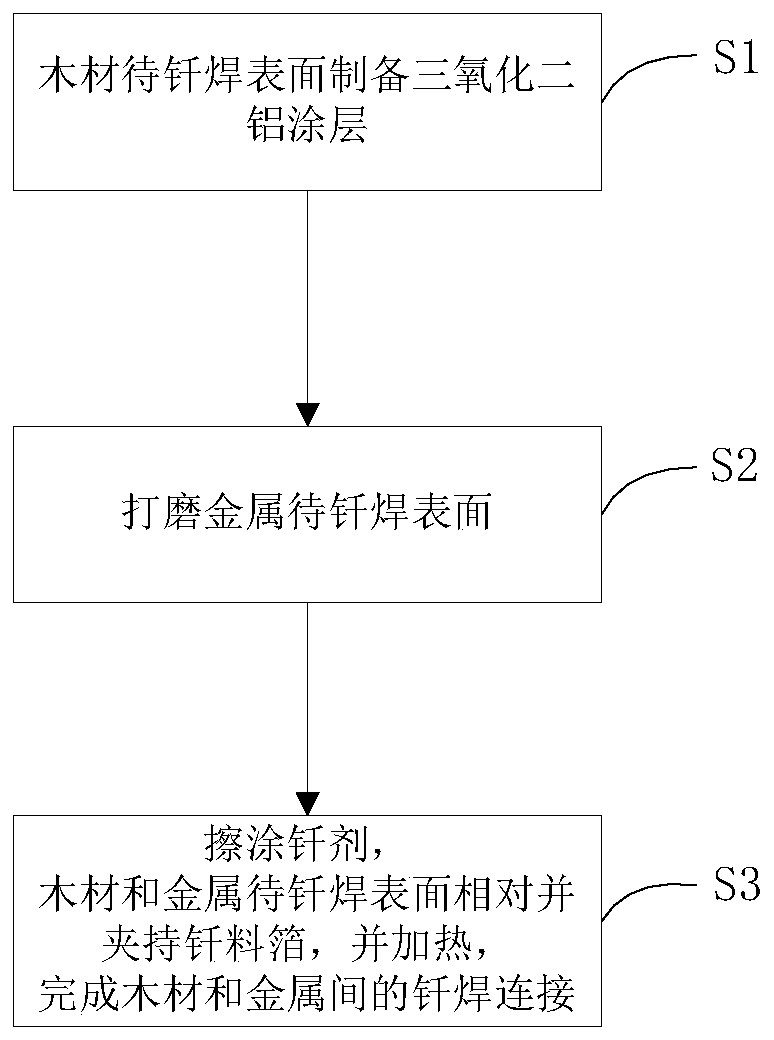

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] see figure 1 As shown, the present invention provides a brazing method between wood materials and metals, which is used to connect the wood of the insulation layer of the low-temperature liquid cargo tank wall of liquefied natural gas and liquefied petroleum gas transport ships with the low-temperature liquid cargo tank wall, and the low-temperature liquid cargo tank wall The cargo wall is generally made of Invar steel. In this example, the melting point of the metal is greater than 200°C, and the air-dry density of the wood is greater than 0.35g / cm 3 , the brazing method specifically includes the following steps:

[0024] Step S1: Prepare an aluminum oxide coating on the surface of the wood to be brazed. The aluminum oxide coating on the surface of the wood to be brazed is prepared by a low-pressure cold spraying process. The thickness of the aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com