Corner installation structure

An installation structure and corner technology, applied in building components, building structures, buildings, etc., can solve the problems of increased manufacturing cost, exposed surface wear, increased processing area, etc., so as to reduce installation gaps, reduce gaps, and improve aesthetics. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

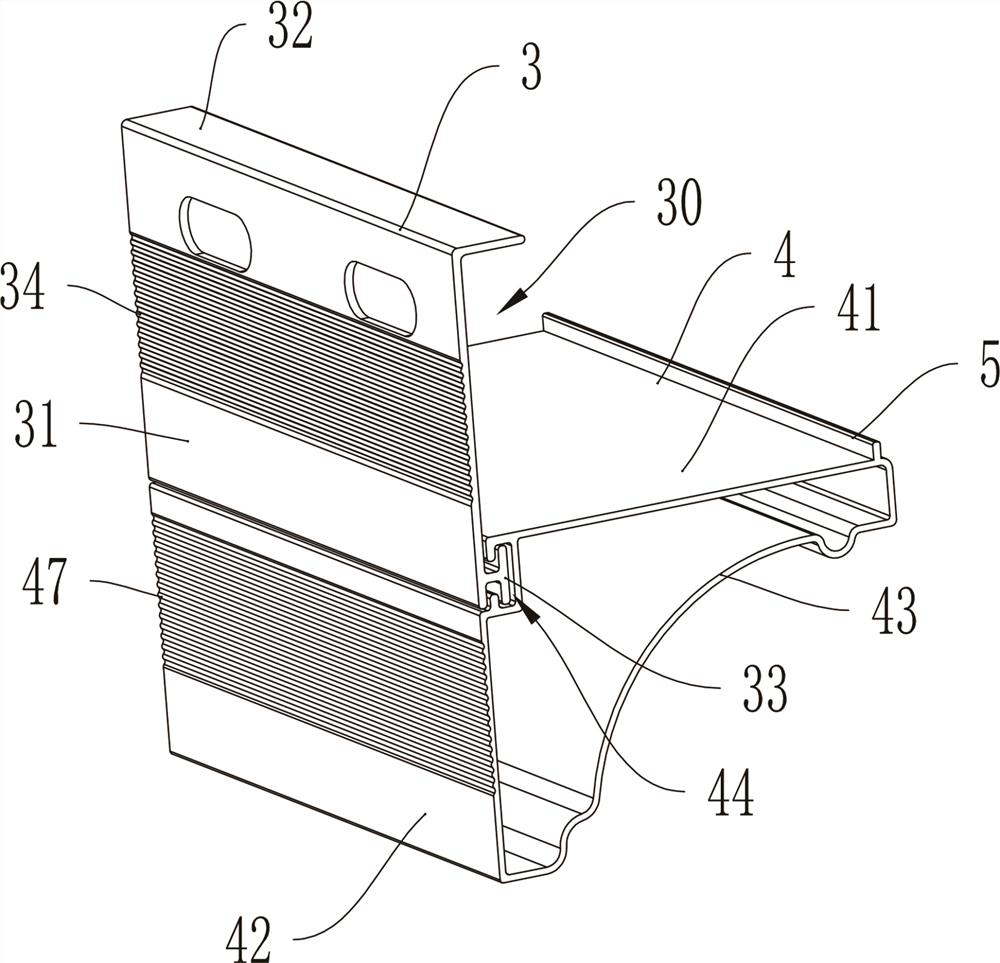

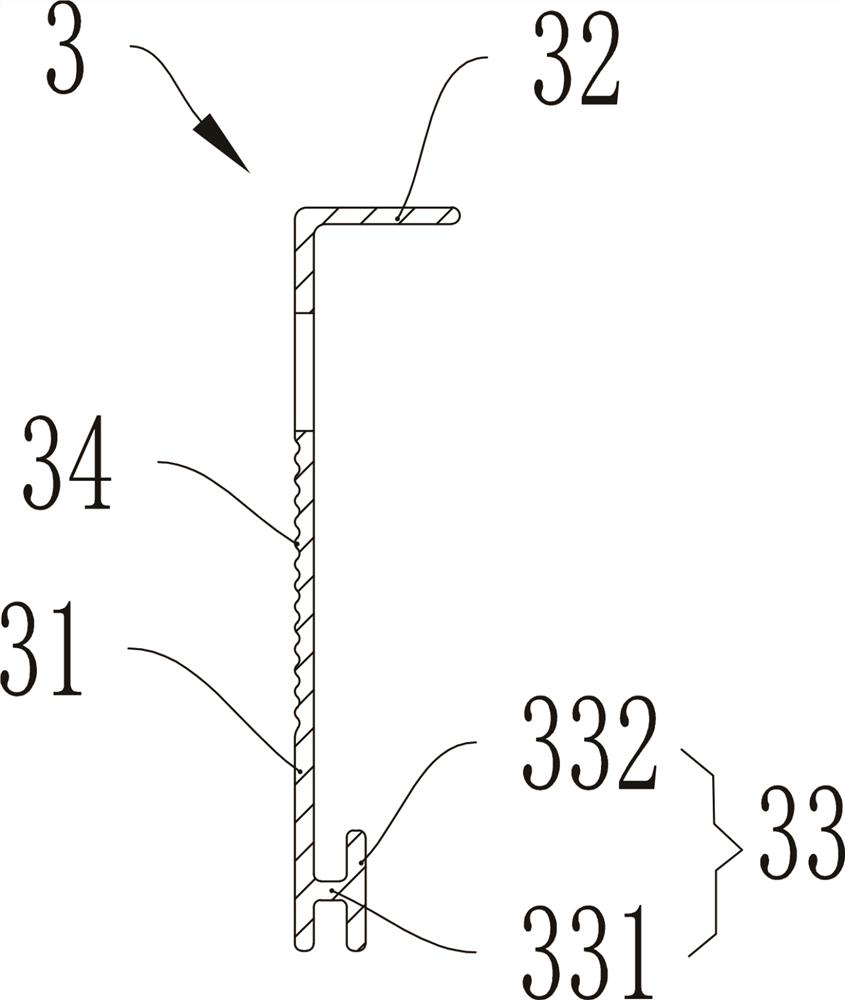

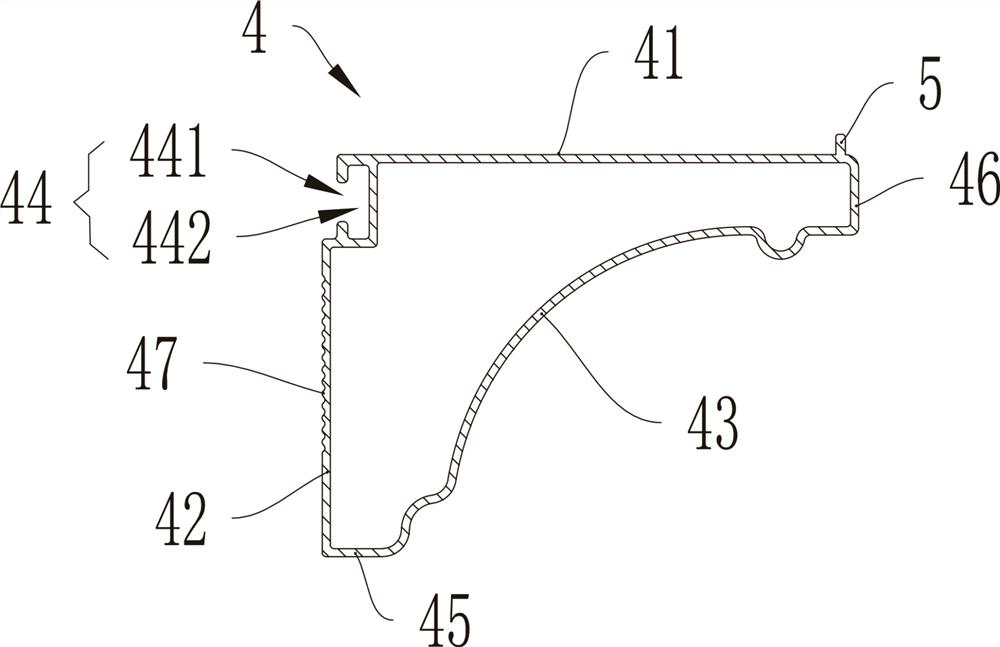

[0026] When installing the ceiling, using the corner installation structure can well solve the connection and transition problem between the ceiling layer 1 and the vertical wall facade 2, and in order to further improve the connection effect between the corner installation structure and the ceiling layer 1 and the vertical wall facade 2 , the corner installation structure applying the technical solution of the present invention will be further described below in conjunction with the accompanying drawings. In addition to clearly stating that they belong to equivalent or optional implementations, the various implementation details disclosed below can be selectively applied or combined in one embodiment even if there is no direct correlation or synergistic relationship in terms of functions. .

[0027] Such as figure 1 and Figure 4 As shown, the corner installation structure is arranged at the corner of the suspended ceiling layer 1 and the vertical wall facade 2, and the corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com