Supporting device for industrial carrying robot

A technology for handling robots and supporting devices, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of reduced work efficiency, lack of flexibility, time-consuming and labor-intensive, etc., and achieve the effect of high work efficiency, diverse functions, and increased stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

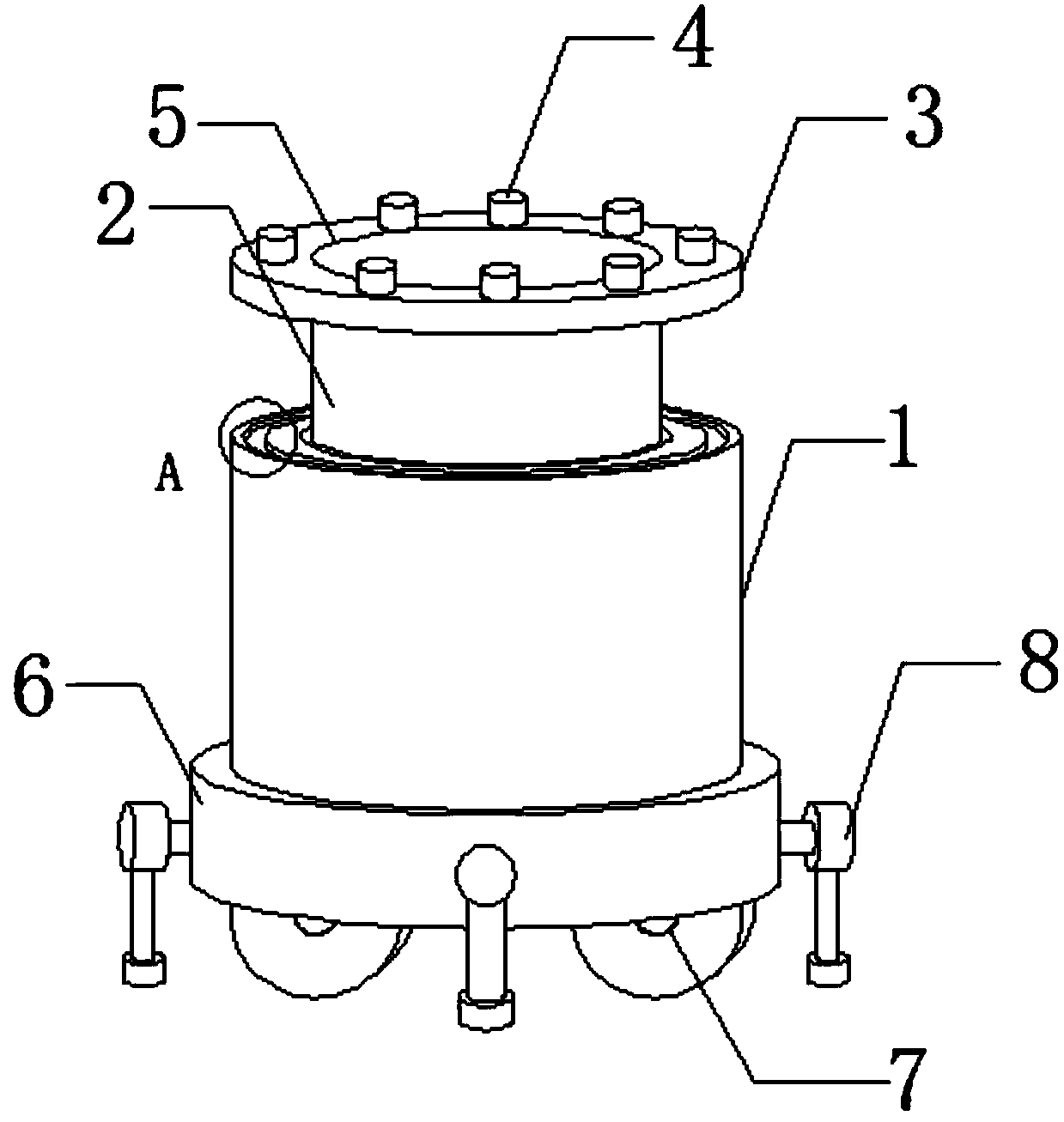

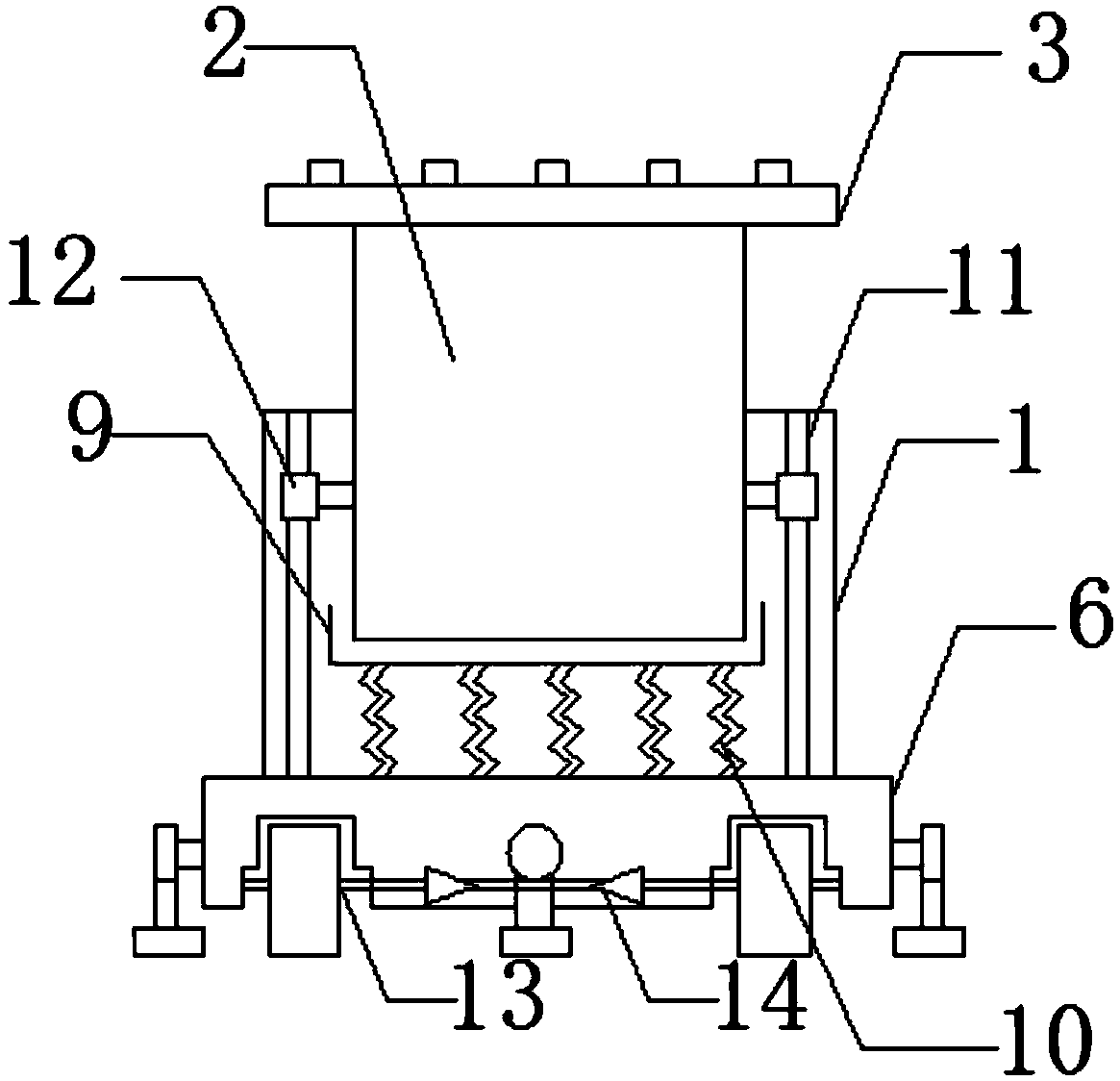

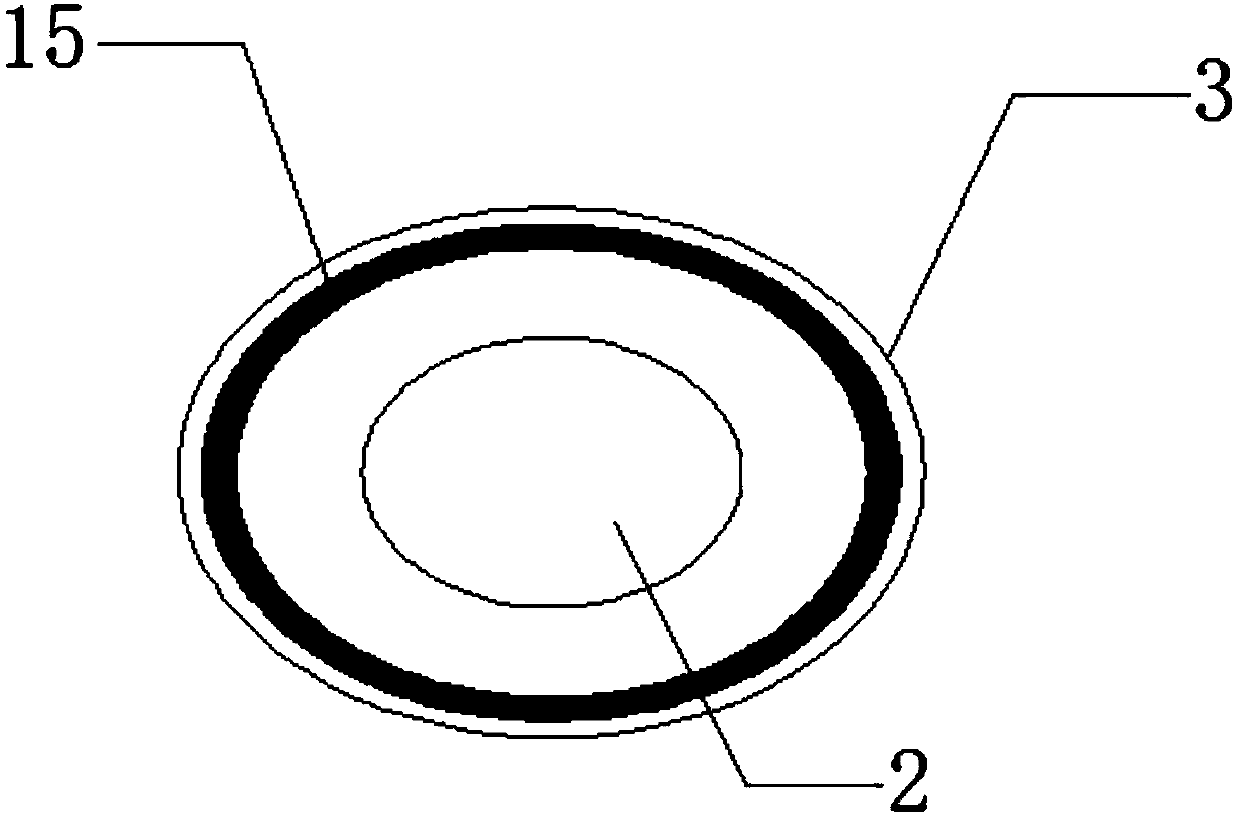

[0025] see Figure 1-5 As shown, a support device for an industrial handling robot includes a sealing box 1, a tray 3 and a base 6, an extension column 2 is installed on the top of the sealing box 1, and a tray 3 is installed on the top of the extension column 2, and the tray 3 is used as a supporting plate for the robot The top of the tray 3 is provided with several connection bolts 4, and the middle part of the tray 3 is provided with a notch 5, and the robot is stably installed on the tray 3 through the connection bolts 4 and the notches 5; The main supporting point; several walking wheels 7 are installed on the bottom of the base 6, and the device has the ability to move through the walking wheels 7; several supporting components 8 are installed on the side wall of the base 6, and the top pressure plate 9 is installed inside the sealing box 1, and the top pressure plate 9 Several return springs 10 are installed at the bottom, and several longitudinally placed sliding rods ...

Embodiment 2

[0027] see figure 2 , image 3 and Figure 5 The difference between it and the above embodiment is that a connecting rod is provided at one end of the sliding bolt 12, and the sliding bolt 12 is fixedly connected with the extension column 2 through the connecting rod, so that the extension column 2 can move up and down stably through the fixing of the sliding bolt 12 and the sliding rod 11 ; when the support bar 20 is vertically placed, the position of the rubber pad 21 is flush with the walking wheel 7, so that the support bar 20 and the rubber pad 21 can stably support the device while not affecting the stable contact between the walking wheel and the supporting surface; the servo motor 19 The internal rotor is rotationally connected to the shaft wheel 17 through the shaft sleeve 18, and the shaft sleeve 18 is flexibly connected to the shaft wheel 17, so that the servo motor 19 can give the shaft wheel 17 the required power source without affecting the stability and fixati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com