Molding device suitable for automobile trim processing

A technology for forming equipment and automotive interiors, applied in the field of automobile manufacturing, to achieve the effects of firm connection, leak prevention, and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

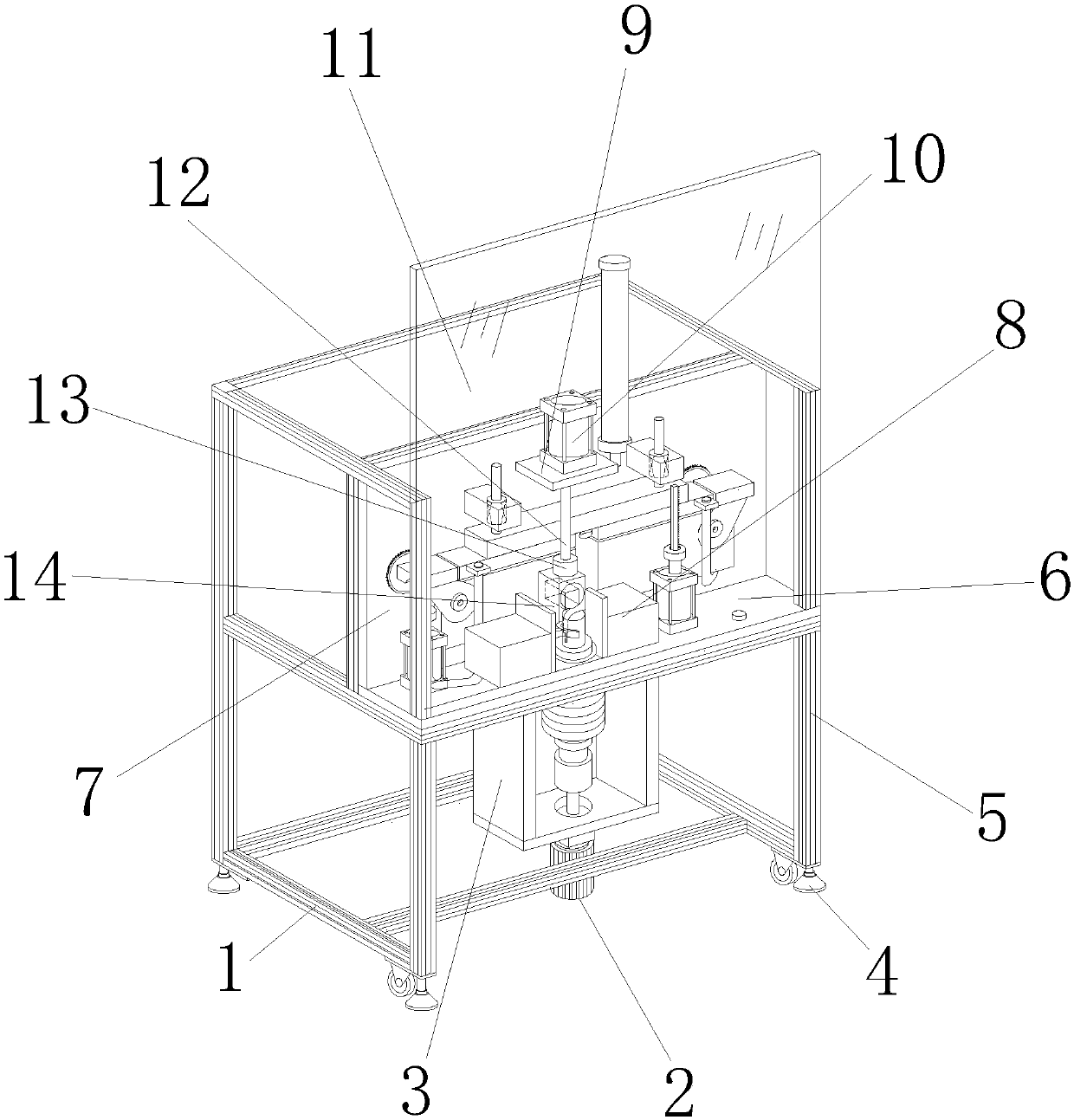

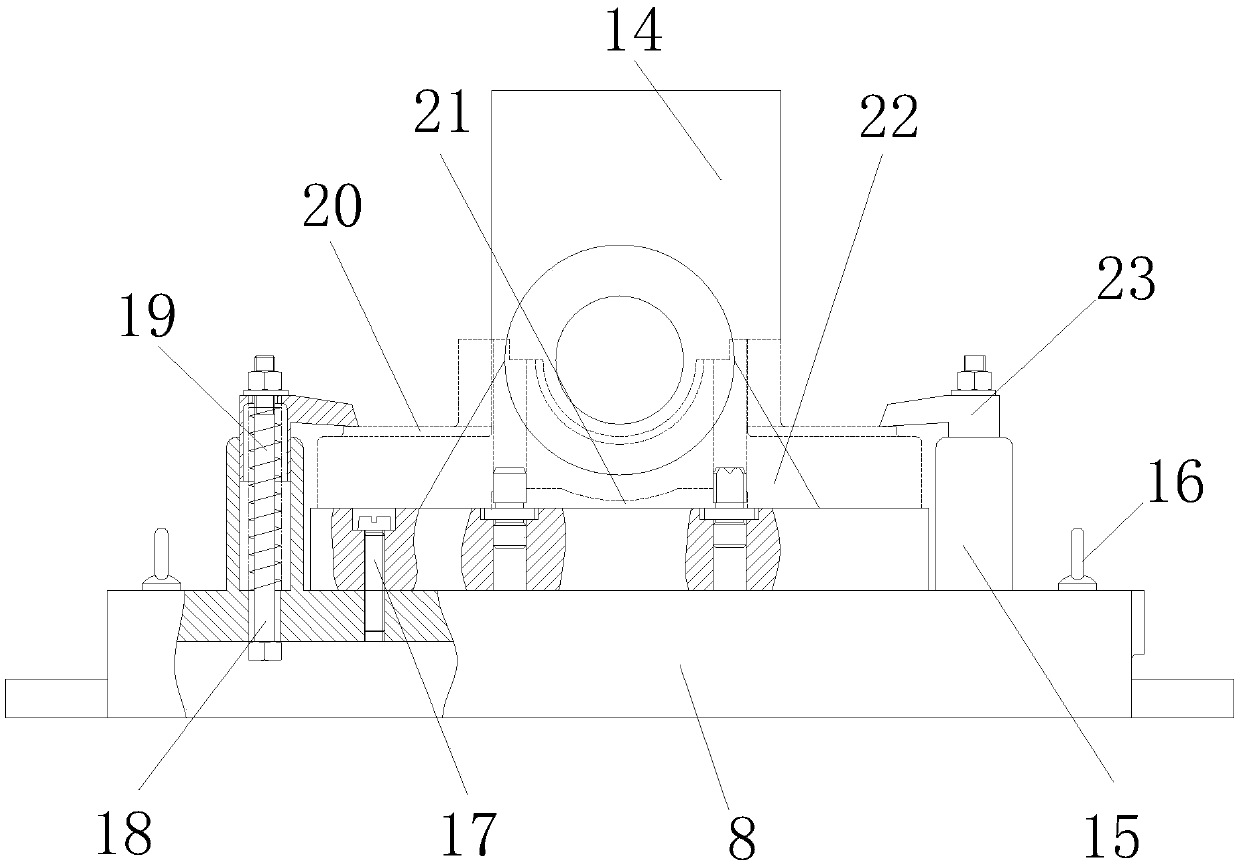

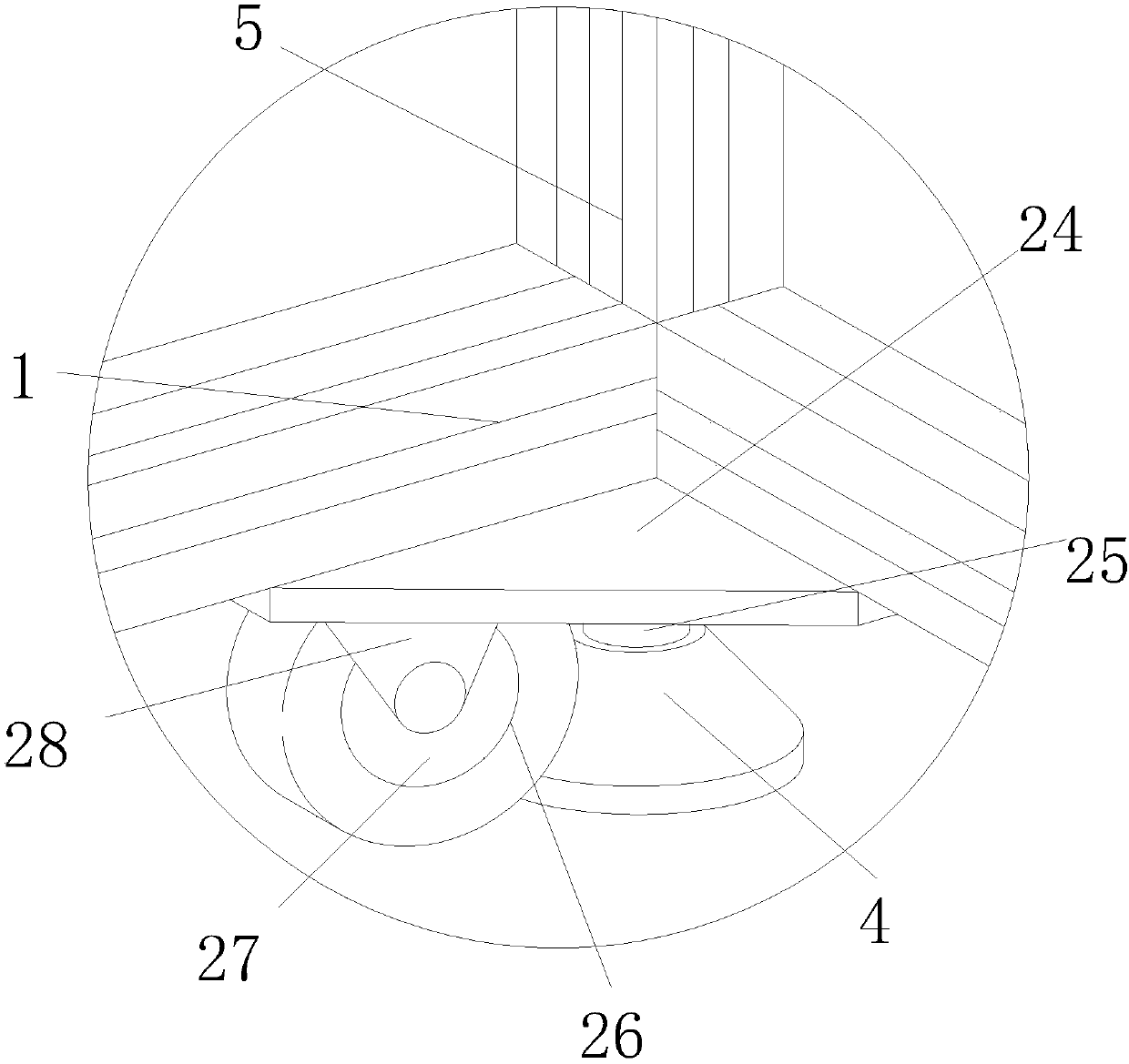

[0015] see Figure 1-3, the present invention provides a technical solution: a molding equipment suitable for the processing of automobile interior decoration, including a base 1, the base 1 is made of stainless steel, and is used to install the frame 5, and the junction between the outer wall of the base 1 and the outer wall of the frame 5 is installed with Supporting plate 24, supporting plate 24 is made of stainless steel, is used for fixing roller 26 and rubber pad 4, uses when being used for mobile equipment, the inner wall of supporting plate 24 is connected with the outer wall of base 1 and frame 5 respectively, the lower surface of supporting plate 24 Bearing pin 25 is installed, and pin shaft 25 is made of stainless steel, is used for installing and fixing rubber pad 4, and the inner wall of pin shaft 25 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com