Novel non-power bogie assembly of motor train unit with speed per hour of 250 km/h

A technology for EMUs and bogies, which is applied to the lateral relative movement device between the chassis and the bogie, and the installation of axle boxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

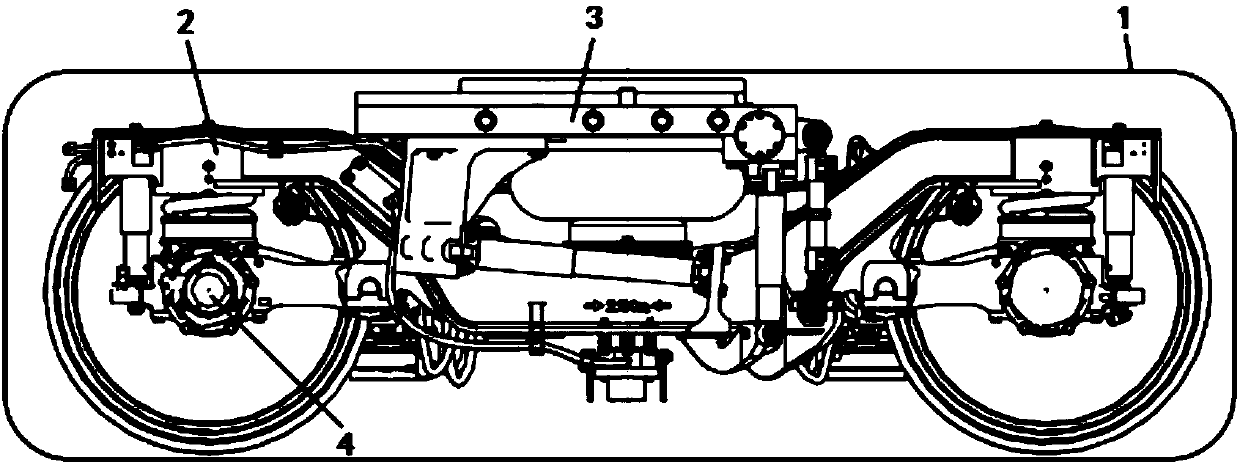

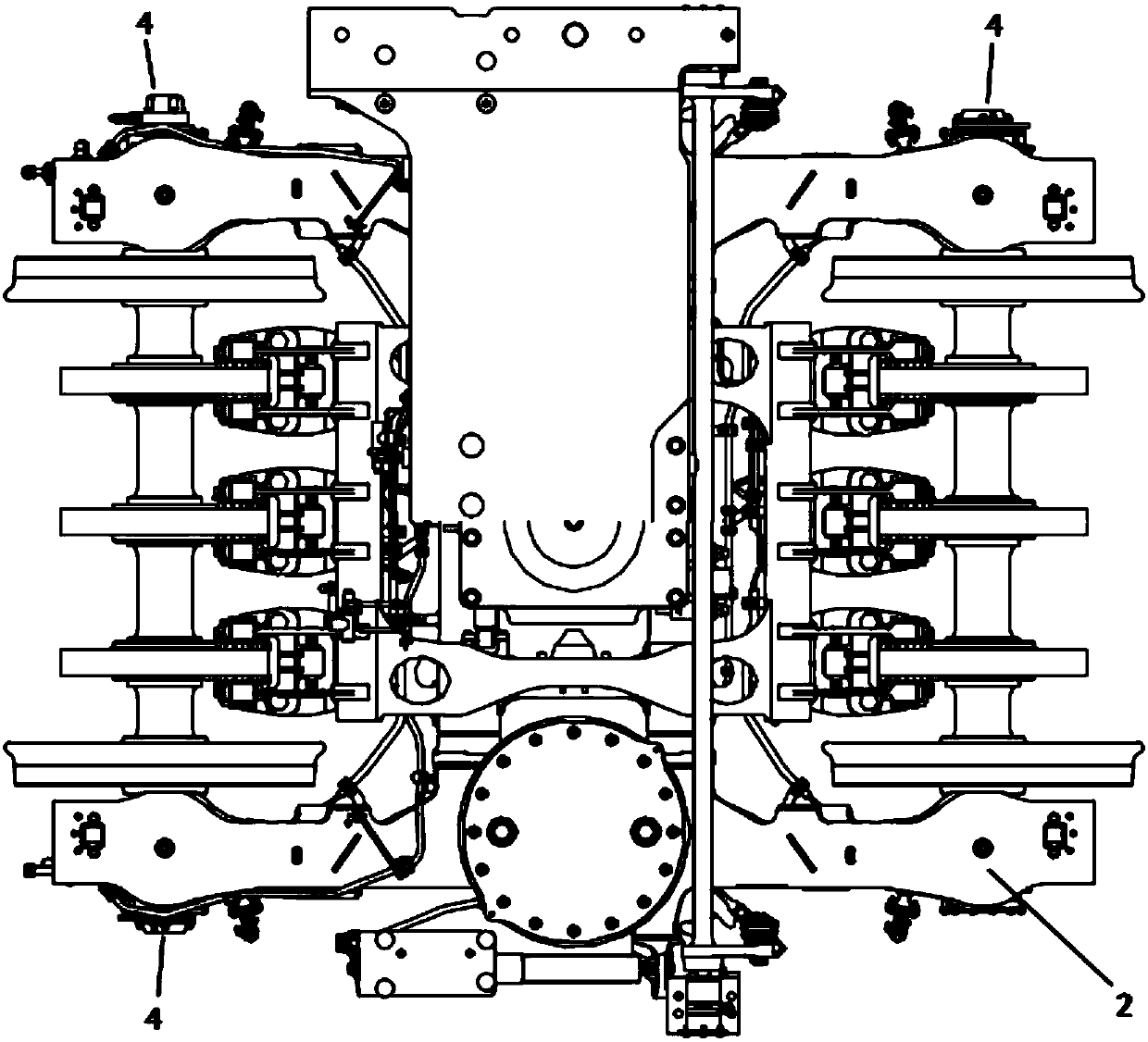

[0017] Such as figure 1 , figure 2 Shown is the new type 250km / h EMU non-powered bogie assembly 1 of the present invention, and its innovative point is to redesign the frame 2, the contact bolster 3, and the axle end 4.

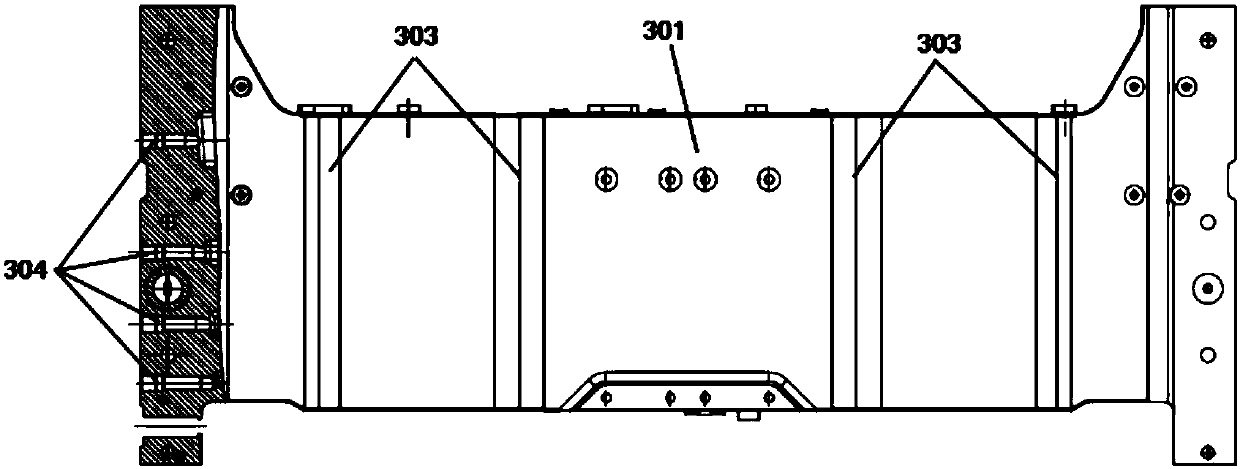

[0018] Such as Figure 3-Figure 6 The frame shown: its innovative point is the structural design of the anti-snaking shock absorber seat 201, the secondary vertical shock absorber seat 202, and the anti-rolling torsion bar seat 203. Among them, the anti-snaking damper seat 201 is the interface 204 designed for the anti-snaking damper, and the rib plate 205 is used to connect the anti-snaking damper seat and the frame, which simplifies the structure relatively and is suitable for 200-250km / h Speed grade; the secondary vertical shock absorber seat 202 is designed to install the cylindrical nut with an installation interface of 206. After setting this interface, in order to make the single part meet the strength requirements, the remaining dimensions are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com