Method for quantizing and adjusting edge airflow of blast furnace

An edge airflow, blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of collapsing sliding scales, unfavorable blast furnace longevity, and complicated operating conditions and distribution methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. Calculation of coke load index and distribution platform width

[0015] This article uses the paper "Research and Application of Large Blast Furnace Fabric Model" (published in "Journal of Northeastern University" (Natural Science Edition), Volume 37, Issue 5, May 2016, Authors: Li Zhuangnian, Liu Zhenggen, Chu Mansheng, Chen Shuwen) The method establishes a blast furnace charge distribution model, and calculates the falling point of the blast furnace charge and the radial thickness of each ring of charge under different charge parameters. Explanation: The calculation method of the charge drop point and the radial thickness of each circle of charge is not limited to the calculation method of the charge distribution model.

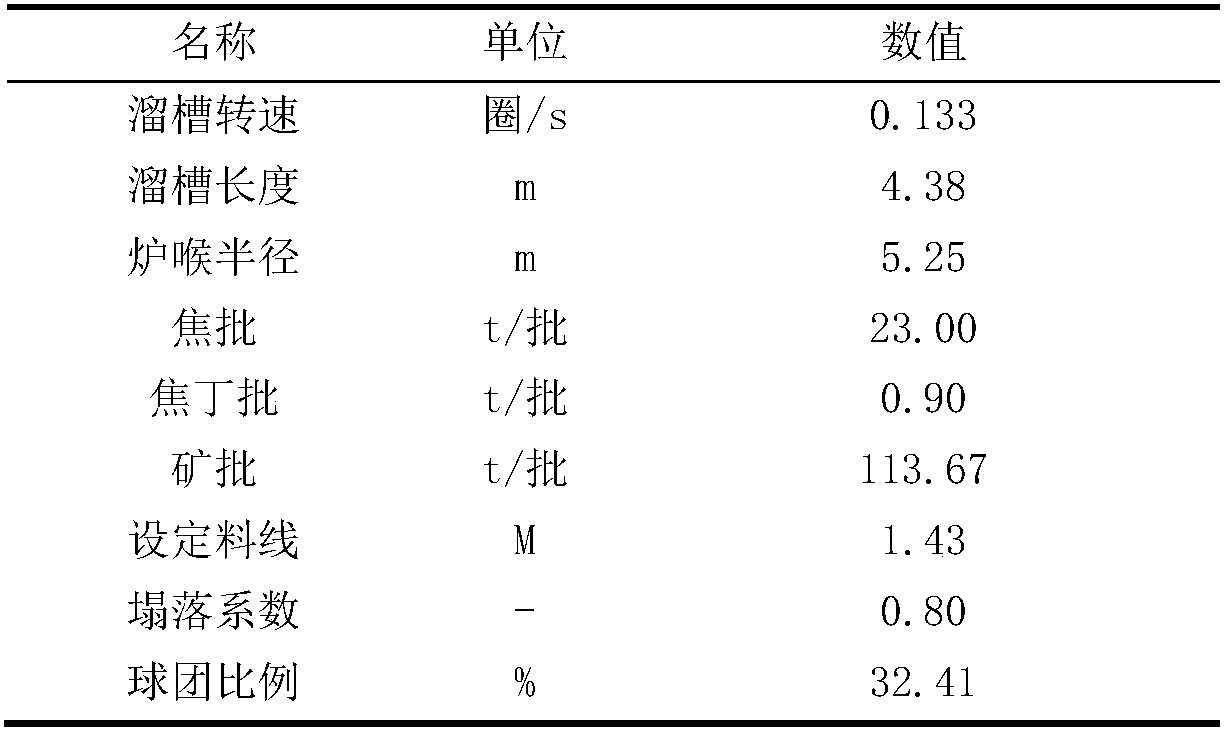

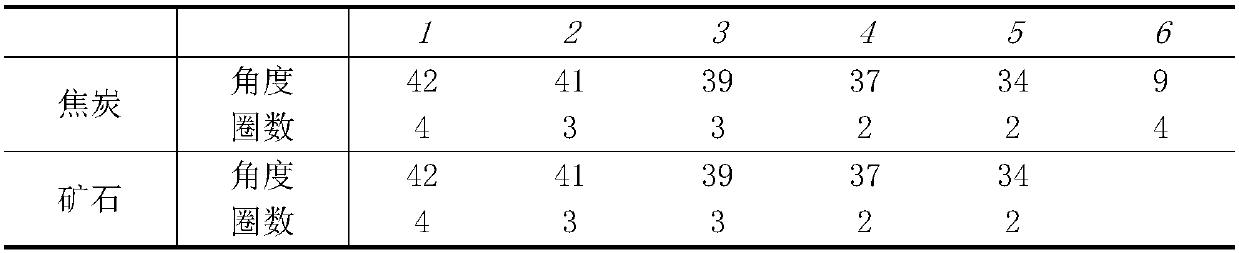

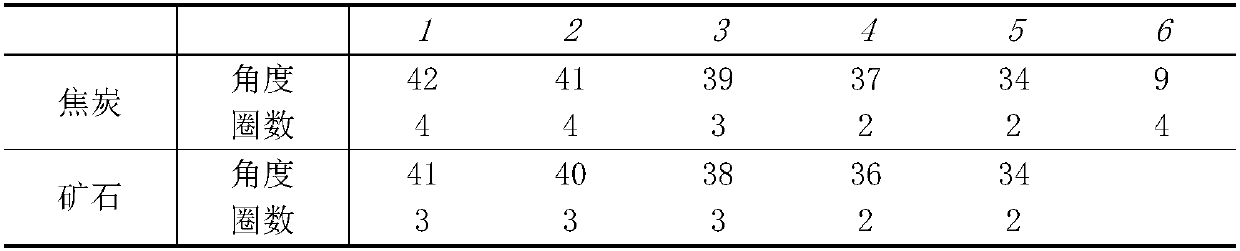

[0016] The input items of the cloth distribution model include: the speed of the chute, the length of the chute, the radius of the furnace throat, the mass of the charge (sintering, pellets, coke, coke) m 炉料 , charge ratio, natural pile angle, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com