Corner brace fixing and edge closing part, prefabricated tile external corner and mounting method of prefabricated tile external corner

An installation method and a technology for fixing connectors, which are applied in covering/lining, construction, building construction, etc., can solve the problems of low construction efficiency, messy site, and cumbersome installation process of external corners of tiles, etc., and achieve convenient and fast installation , the effect of increasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

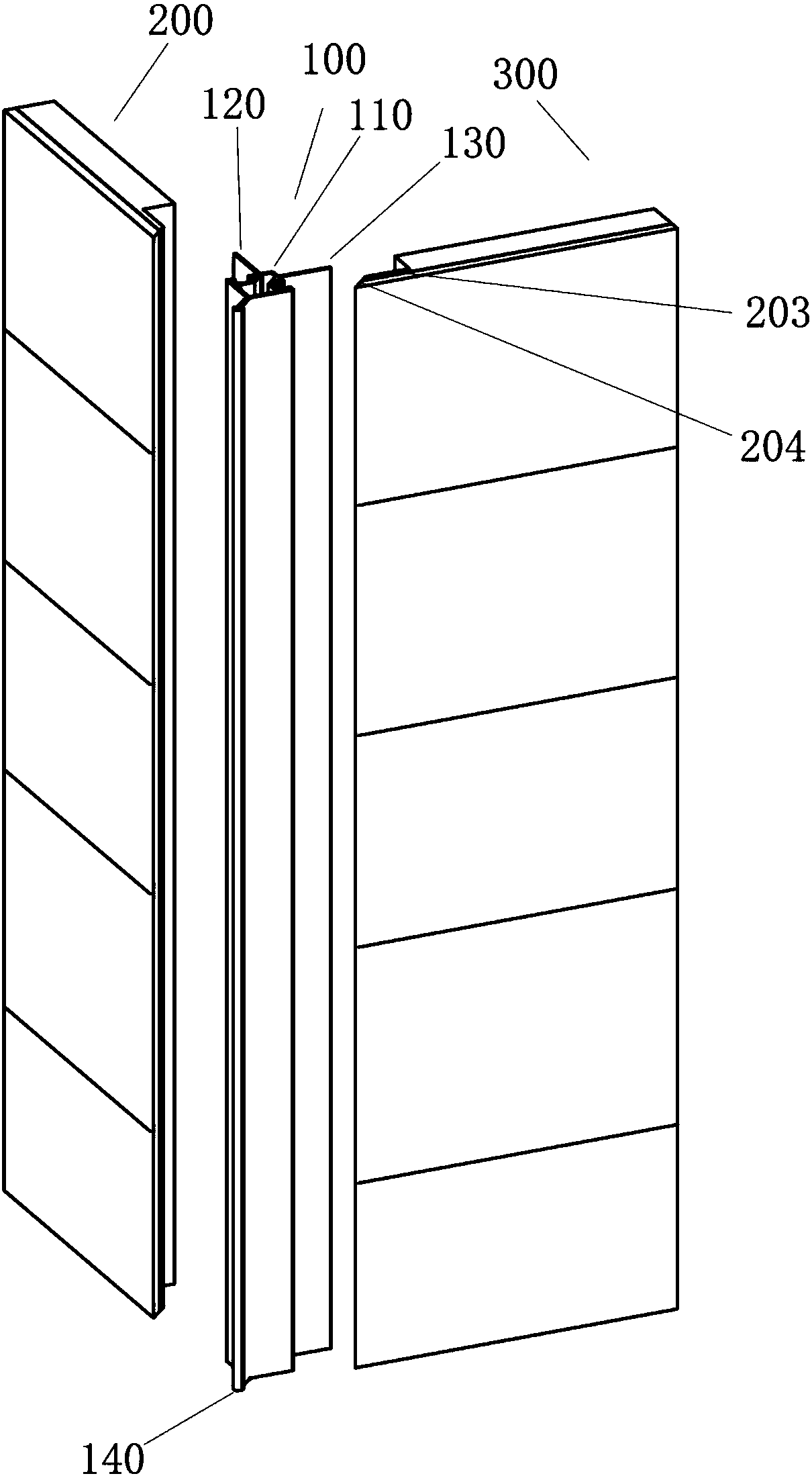

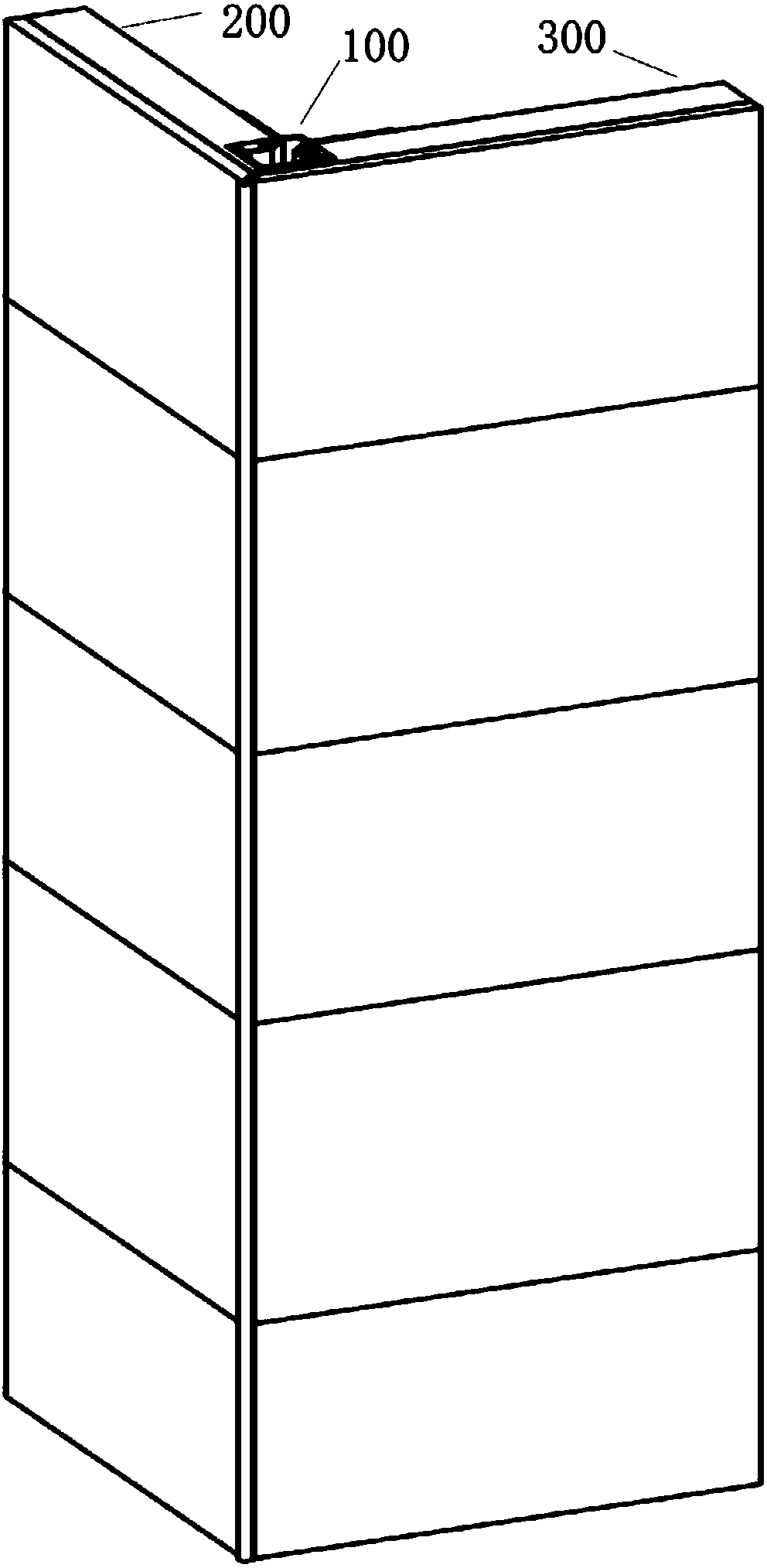

[0023] Such as figure 1 As shown, in the exploded schematic view of the male corner of the prefabricated tile in the first embodiment of the present invention, the corner fixing fixing part 100 , the first board 200 and the second board 300 are shown.

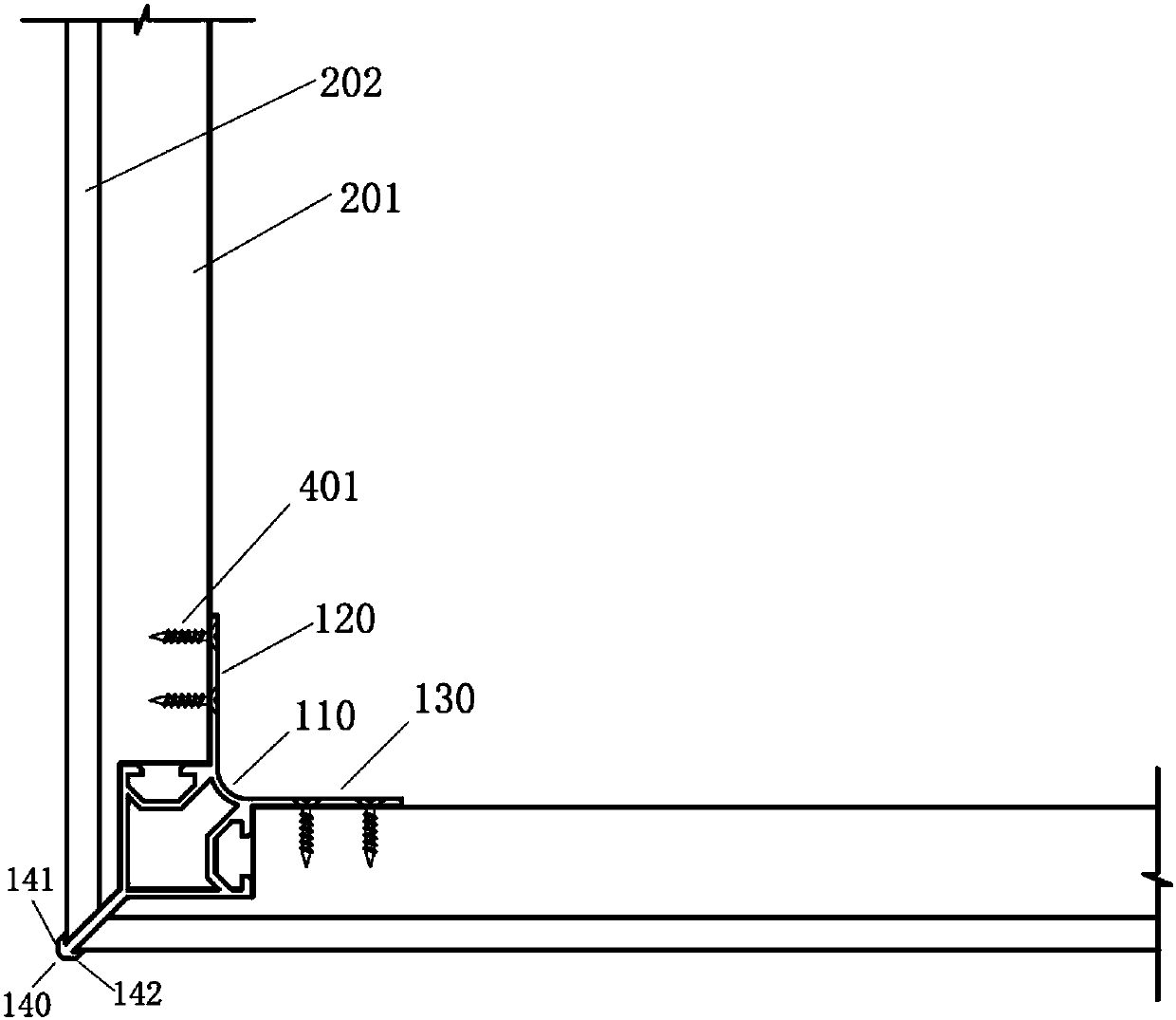

[0024] The corner code fixing edge trimming component 100 includes a frame body 110 , a first panel connecting portion 120 , a second panel connecting portion 130 , and a third panel connecting portion 140 . in:

[0025] The first panel connecting portion 120 for connecting the first panel 200, the second panel connecting portion 130 for connecting the second panel 300, and the second panel connecting portion 130 for connecting the first panel 200 and the second panel 300 at the joint The third panel connecting portions 140 of the first panel and the second panel both extend outward from the frame body 110 . In this embodiment, the frame body 110 , the first panel connecting portion 120 , the second panel connecting portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com