Dense oil well carbon dioxide front energy storage composite sand adding fracturing method

A carbon dioxide and sand-added fracturing technology, which is applied in earthwork drilling, wellbore/well components, and production fluids, can solve problems such as low fracture conductivity, poor fracture-making ability, and difficult-to-seal sand-mixing devices. Overcome the dependence on special airtight equipment, enhance the driving pressure and fluidity, and overcome the limited effect of energy-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

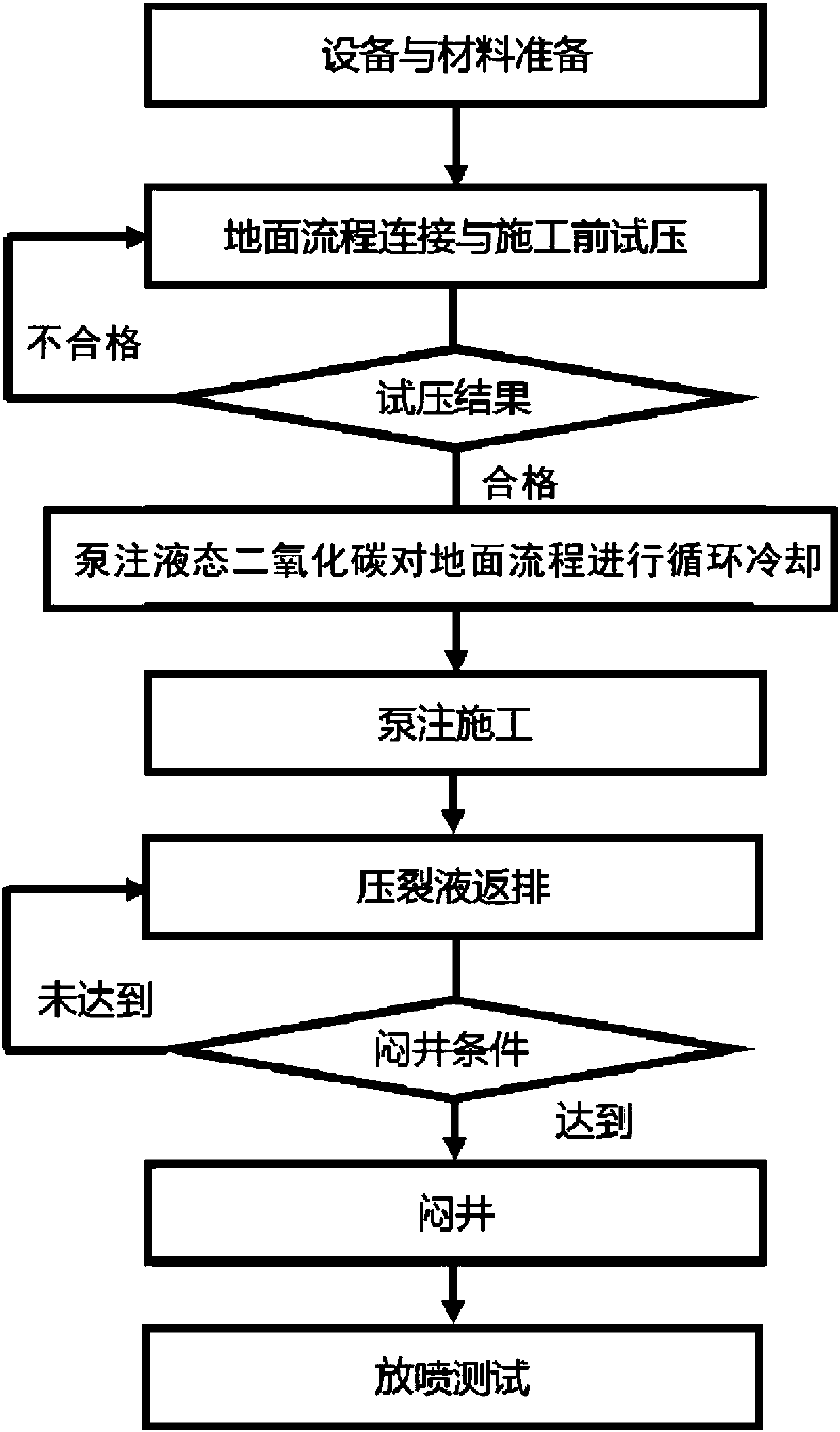

[0027] Such as figure 1 , figure 2 As shown, the carbon dioxide pre-energy storage composite sand fracturing method for tight oil wells of the present invention comprises the following steps:

[0028] ⑴ Prepare the corresponding construction equipment and well entry materials according to the design, specifically, prepare liquid carbon dioxide, slick water, carbon dioxide drag reducer, cross-linked fracturing fluid, and fracturing proppant on site, and then connect the surface process and conduct a pressure test on the surface process , the unqualified pressure test needs to be rectified, and the next step will be entered after the pressure test is passed again.

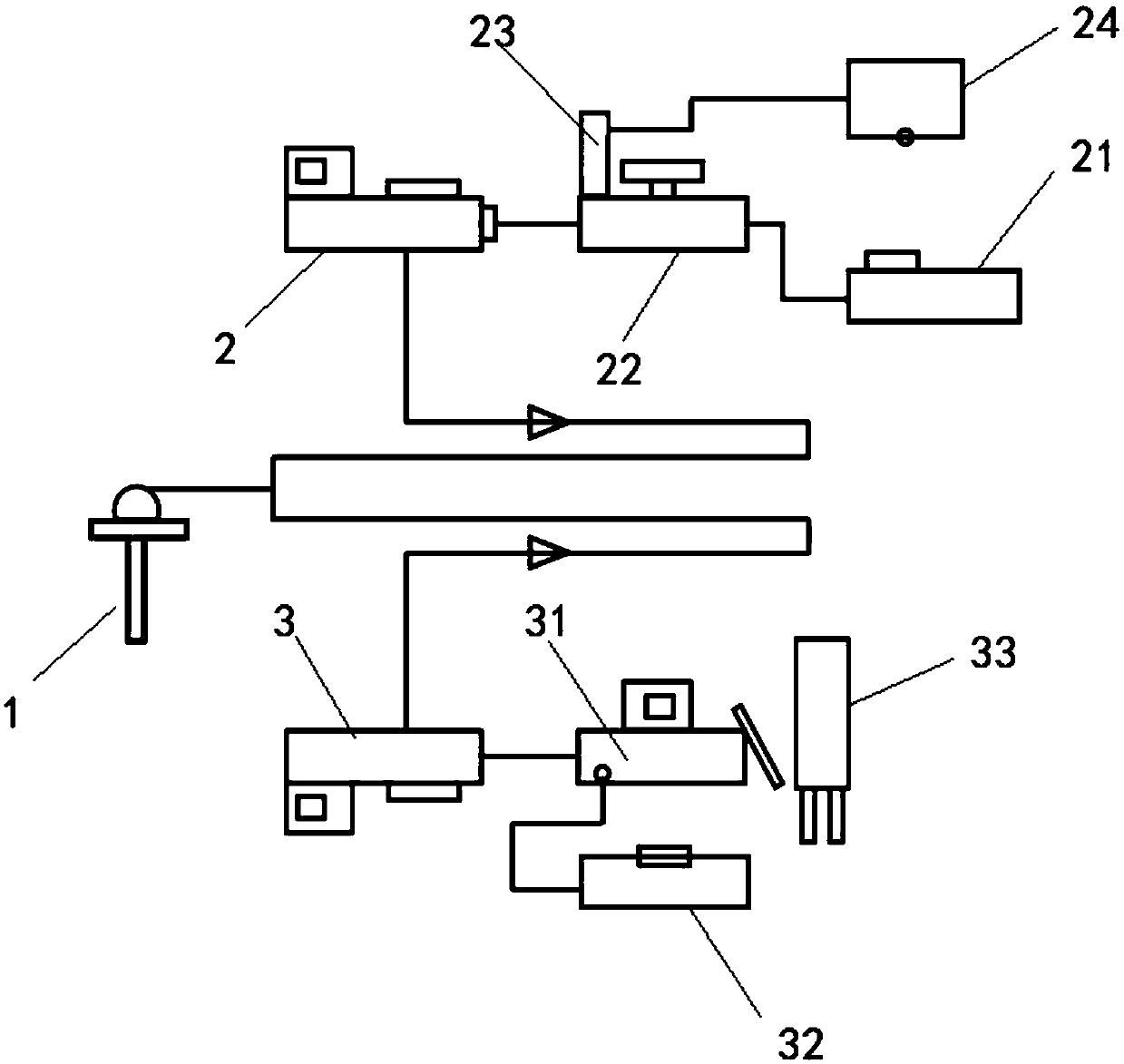

[0029] Specifically, the surface process includes a carbon dioxide fracturing pump truck 2 arranged at the wellhead 1 for pumping liquid carbon dioxide and a conventional fracturing pump truck 3 for pumping slick water, cross-linked fracturing fluid, and fracturing proppant , a carbon dioxide booster pump 22 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com