Large-size wind power gear box

A gear box, wind power technology, used in belts/chains/gears, transmission boxes, components with teeth, etc., can solve the problem of time-consuming and laborious handling, disassembly, and reassembly, difficult to process bearing holes, and difficult machining accuracy. Guarantee and other issues to achieve the effect of shortening production cycle, improving processing quality and production efficiency, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following drawings and in conjunction with the preferred embodiment illustrate the present invention in detail.

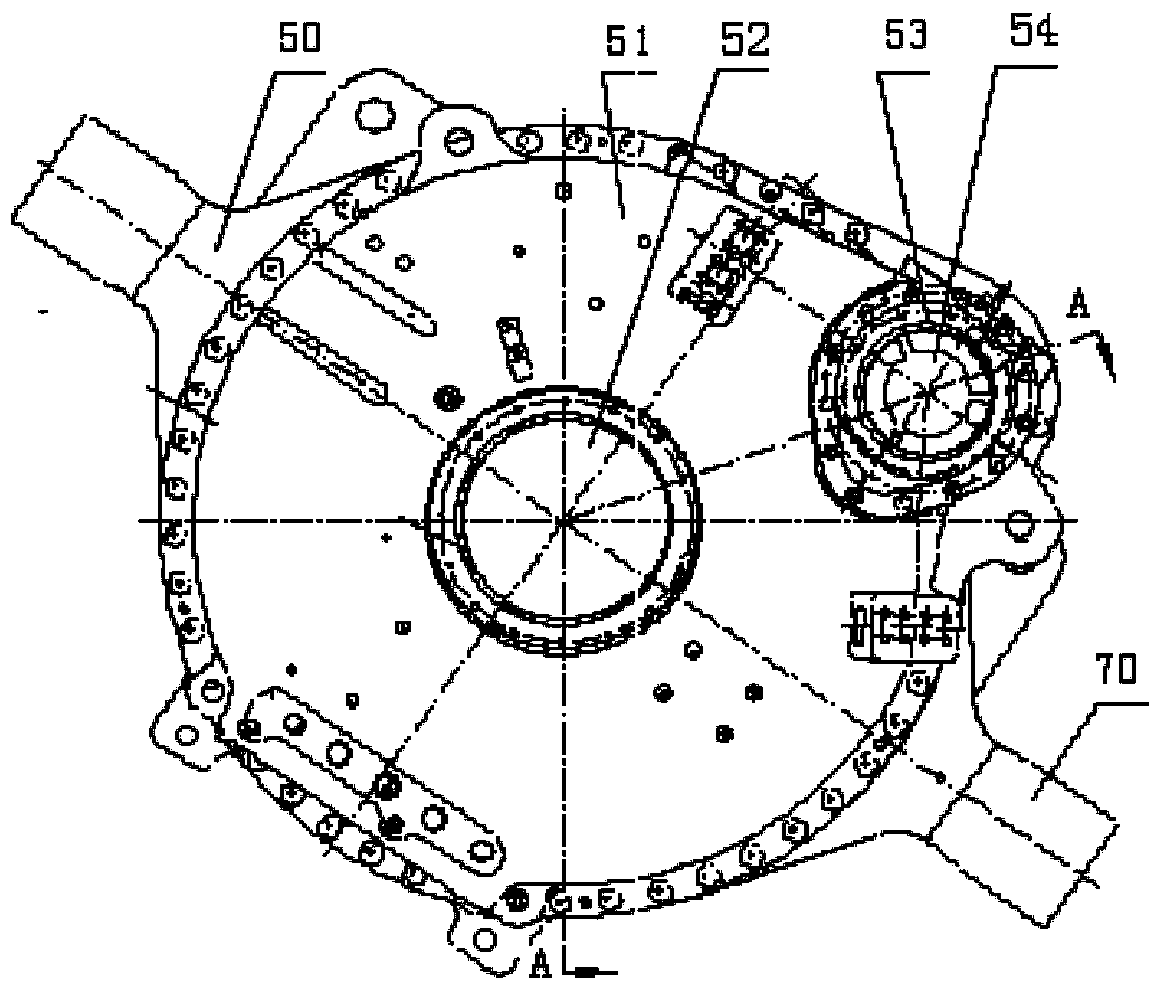

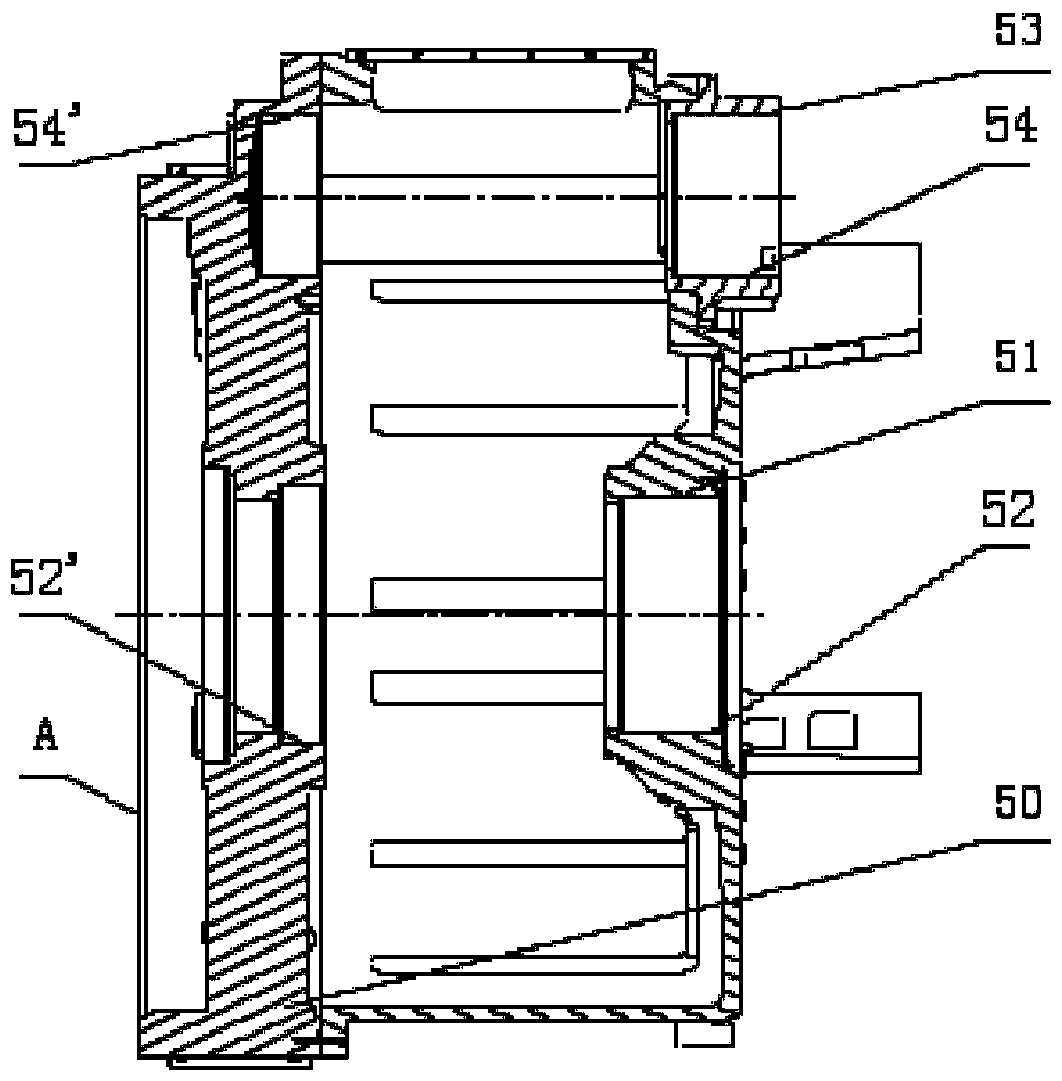

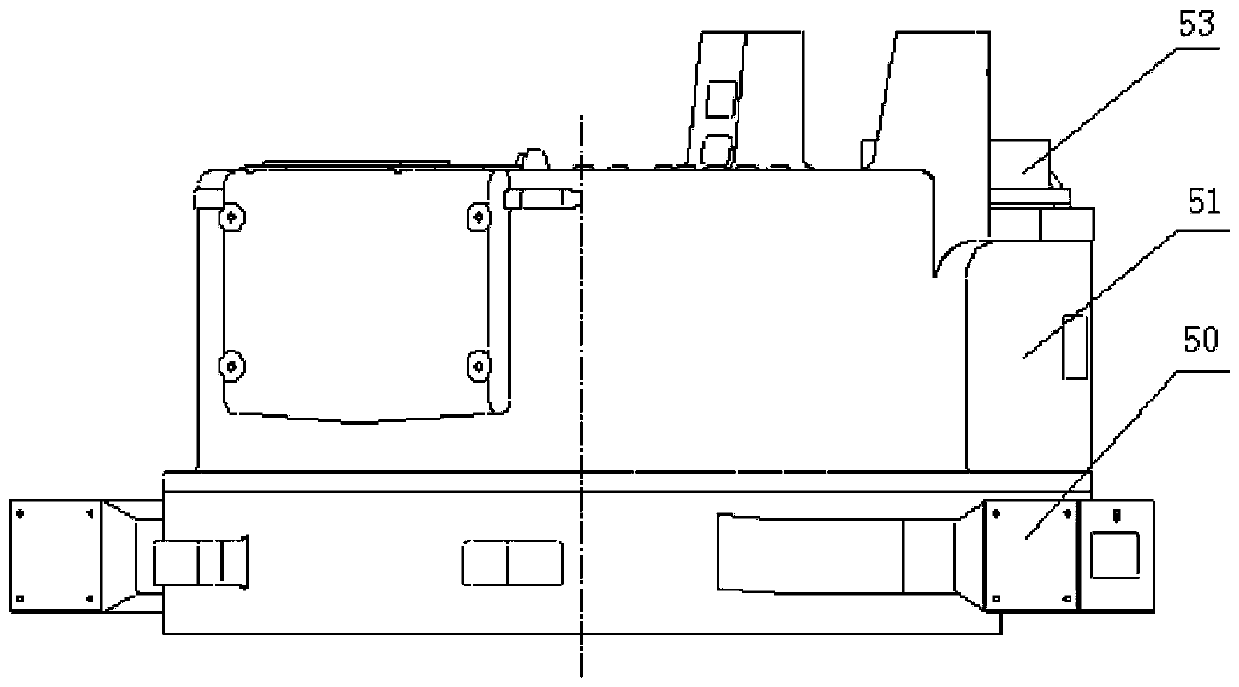

[0029] see Figure 4 to Figure 8 , the large-scale wind power gear case of the present invention includes a rear case 51 and a middle case 50 assembled front and rear, and a rear case cover 53 assembled on one side of the rear case 51 . Wherein, the rear box body 51 is an open box body with a front end and one side opening; the middle part of the middle box body 50 and the rear box body 51 is respectively provided with a coaxial front bearing hole 152 and a rear bearing hole 152 corresponding to the front and rear. '52', on one side of the middle box body 50 and corresponding to the rear box cover 53, there are respectively coaxial front side bearing hole II54 and front side bearing hole II54' which are coaxial and correspond to the front and back. Figure 4 to Figure 8 It can be seen that the present invention also includes four support structures 60, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com