Simple oil separator for automobile air conditioner system

An automobile air-conditioning system and oil separator technology, applied in the field of automobile air-conditioning, can solve the problems of low strength, easy to break, thin capillary, etc., and achieve the effect of fewer components, simple structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

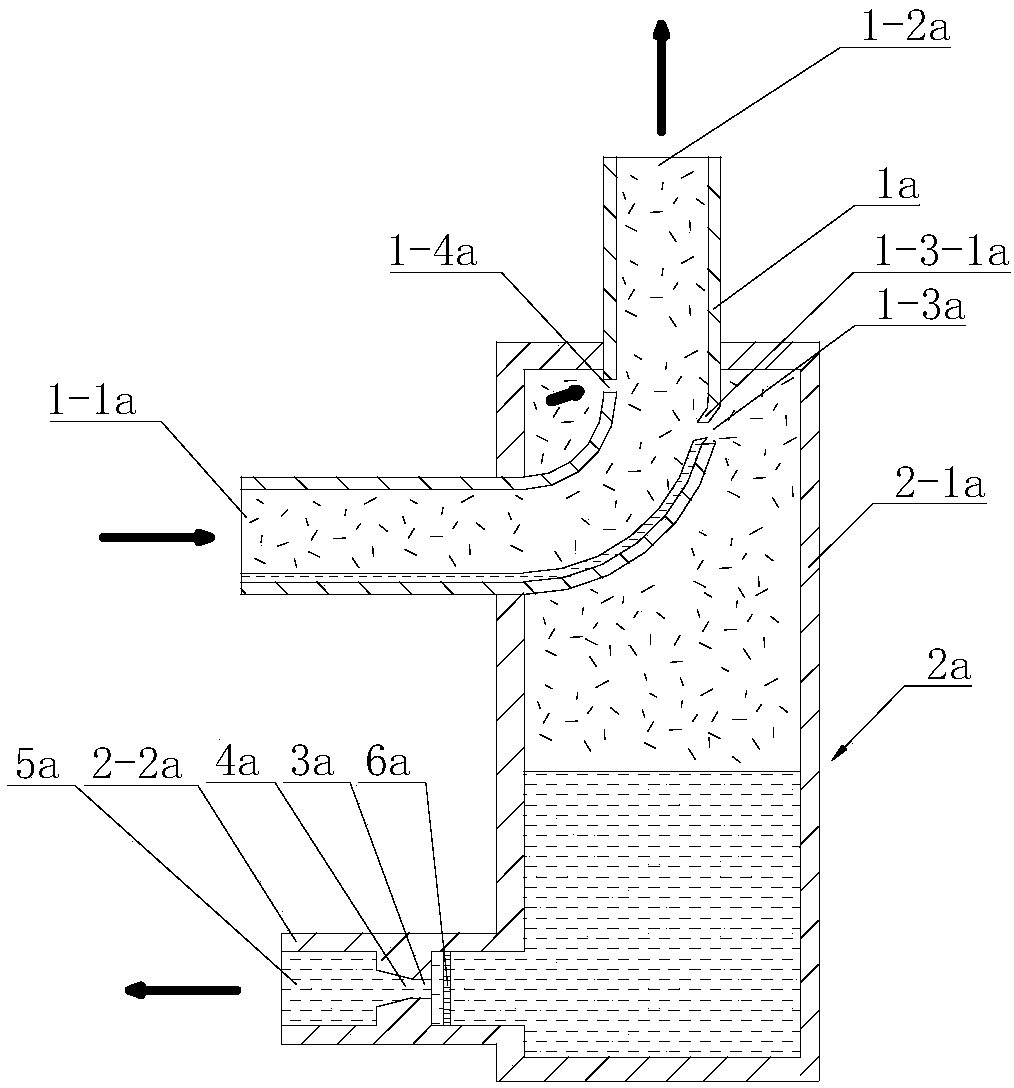

Embodiment 1

[0031] See figure 1 , a simple oil separator for automobile air conditioning system, including oil distribution elbow 1a, oil storage cavity 2a. The oil distribution elbow is composed of two straight pipe sections and an arc-shaped elbow section connecting the two straight pipe sections. The oil storage chamber is composed of a cylindrical or square column main body part 2-1a arranged upright and an oil return output extension part 2-2a arranged on one side of the main body part of the chamber near the bottom. The oil distribution elbow is worn and fixed on the upper part of the oil storage cavity with both ends exposed. The installation direction of the oil distribution elbow is preferably: the plane where it is located and the horizontal plane are within the range of 45° to 90°, preferably 90° °. One end of the oil distribution elbow is the refrigerant inlet port, and the other end is the refrigerant outlet port. Considering the ease of installation and connection and the...

Embodiment 2

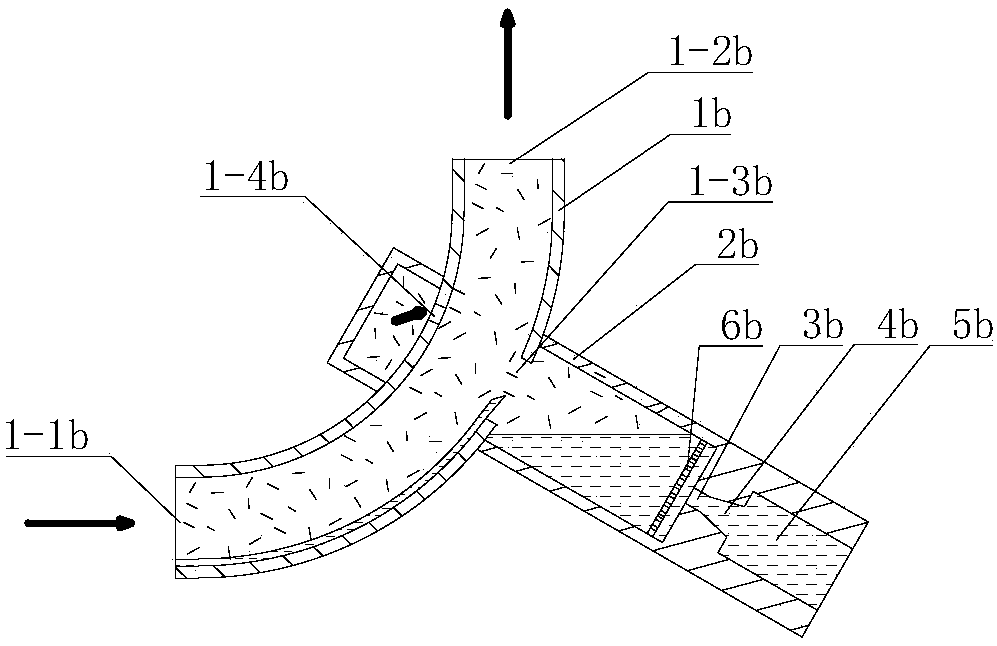

[0041] See figure 2 , the difference between this embodiment and embodiment one is:

[0042] The oil distribution elbow 1b is composed of an arc-shaped elbow, the oil storage chamber 2b is a thin straight tube arranged obliquely, the oil distribution port 1-3b is opened on the arc surface of the side with a larger curvature radius, and the air return port 1-4b The oil return structure formed by the orifice 3b, the oil discharge hole 4b and the oil return port 5b is set directly on the lower end of the oil storage cavity.

[0043] In addition to the above-mentioned features different from Embodiment 1, other structures, such as the arrangement of the refrigerant inlet port 1-1b and the refrigerant outlet port 1-2b, the preferred shape of the oil distribution port, the preferred shape and size parameters of the orifice, the filter screen The settings and the like are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

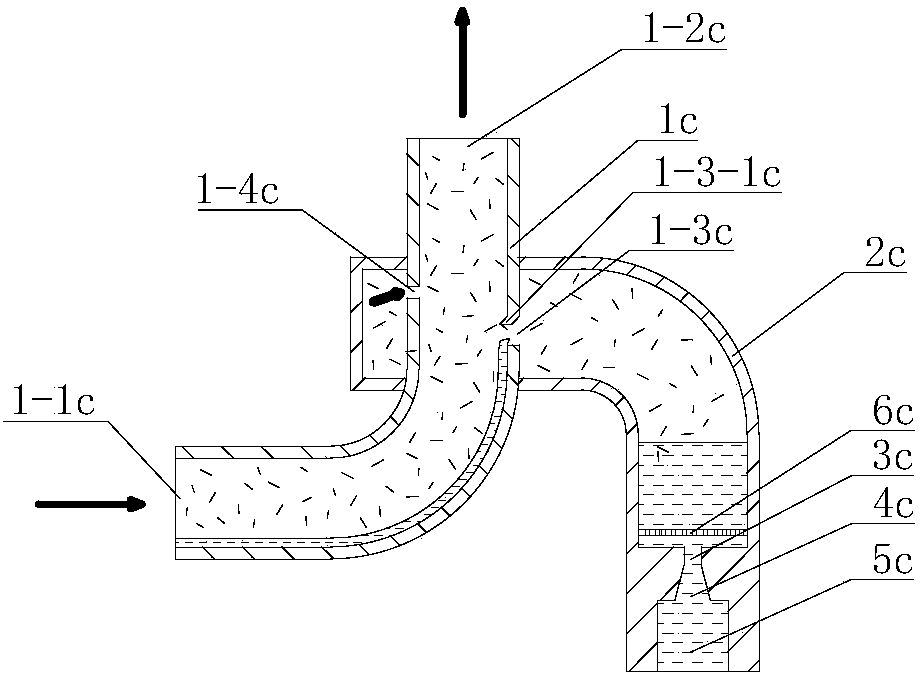

[0045] See image 3 , the difference between this embodiment and embodiment one is:

[0046] The oil storage chamber 2c adopts a thin elbow structure composed of two straight pipe sections and an arc-shaped elbow section connecting the two straight pipe sections, and an oil return structure composed of an orifice 3c, an oil discharge hole 4c and an oil return port 5c Set in the lower straight pipe section.

[0047] In addition to the above-mentioned features different from Embodiment 1, other structures, such as the shape of the oil distribution elbow 1c, the location of the oil distribution port 1-3c, the location of the return air port 1-4c, the refrigerant inlet port 1-1c and the refrigerant The setting of the outlet port 1-2c, the preferred shape of the oil distribution port, the preferred shape and size parameters of the orifice, the setting of the filter screen, the setting of the oil retaining flange 1-3-1c on the oil distribution port, etc. are all the same as in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com