Axial load applying device for products

A technology of axial load and loading device, applied in the field of mechanical testing, to achieve the effect of saving test space, significant production practice significance, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

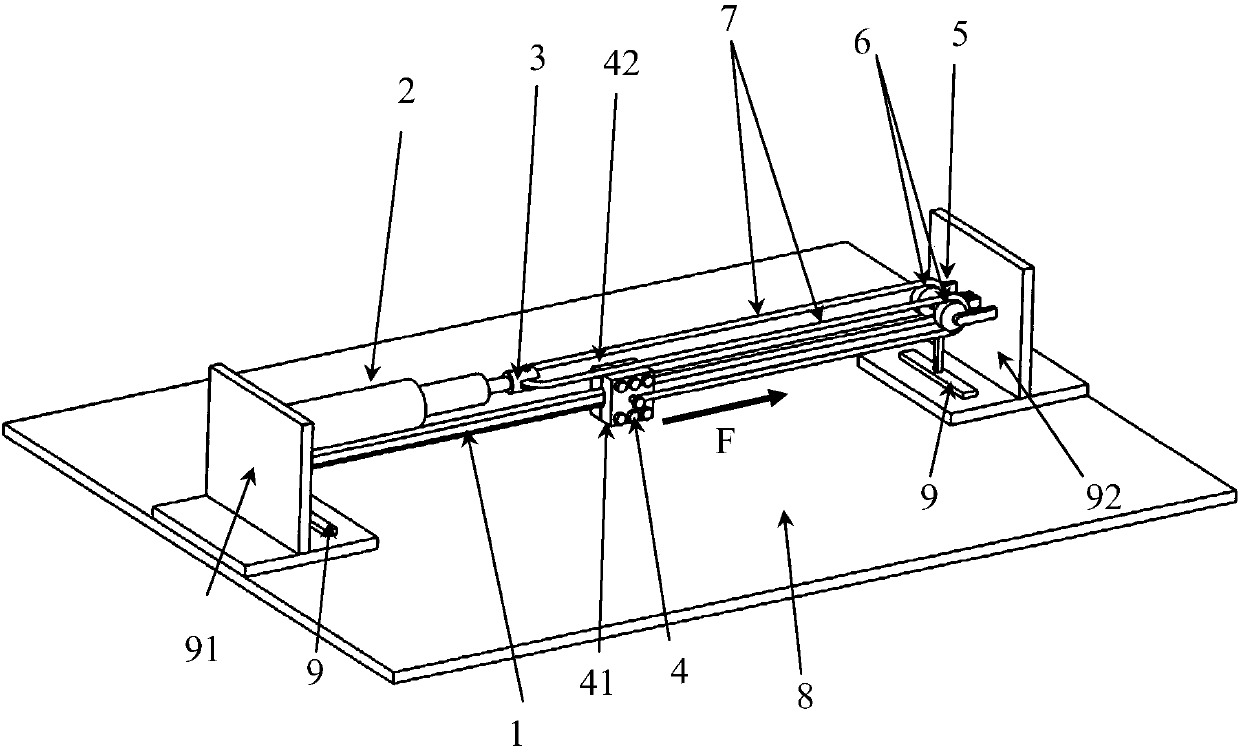

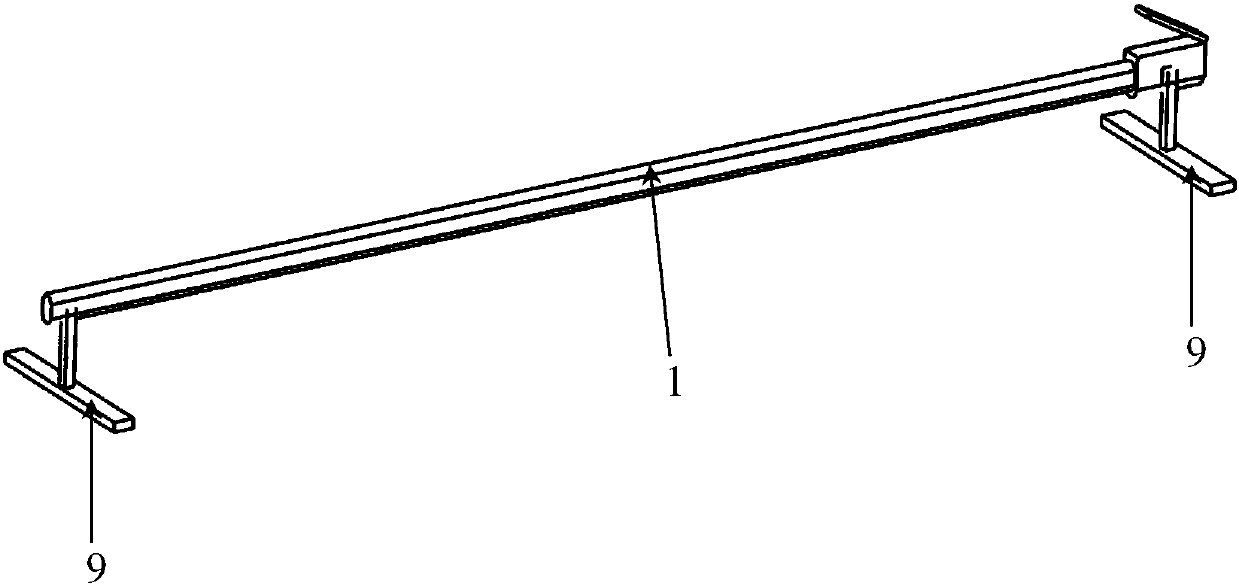

[0025] see Figure 1 to Figure 2 , an axial load loading device for products provided by the present invention, which is mainly used to safely and reliably apply axial loads to products extending in the axial direction, such as telescopic rods, lengthened slide rail combinations, etc., so as to meet the requirements for these products. The product load loading requirement before the axial static load test occupies a small space and can save valuable test space.

[0026] It should be noted that, in the present invention, the product provided by the present invention: the word "telescopic" of the telescopic rod in the combination of telescopic rod and extended slide rail means that when the telescopic rod and the long slide rail cooperate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com