Production method for utilizing electric sparks to remove relay touch oxidation film

A technology of relay contacts and production methods, applied in relays, circuits, electrical components, etc., can solve the problems of stable operation of vehicles, difficult to pass tests, unstable resistance, etc., to extend the service life of equipment, easy to implement, Reasonable effect of production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

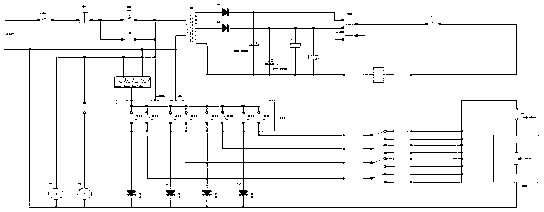

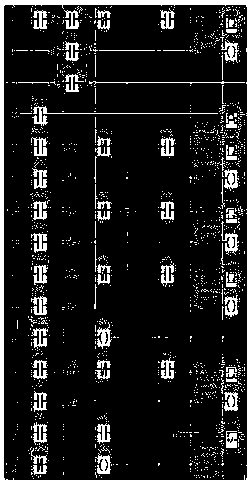

[0022] refer to Figure 1-2 , a production method utilizing electric sparks to remove oxide films on relay contacts, comprising the following steps,

[0023] S1, prepare the following materials: one LOGO or PLC with 220V eight-channel output, one 120Ω 200W resistor, one voltage and current two-in-one digital display meter, two buttons, one 3A circuit breaker, one intermediate relay, one time relay, One rocker switch, one voltage regulating board, one chassis, some common electronic components and consumables;

[0024] S2, Wiring construction: The main functional requirements of the wiring are: a. The start-stop circuit of the power supply; b. The circuit for switchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com