Mobile terminal with antenna-structure intermediate frame and manufacturing method of mobile terminal

An antenna structure and mobile terminal technology, applied in the directions of antennas, antenna parts, antenna supports/installation devices, etc., to save placement space and placement, improve signal transmission, and enhance the overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

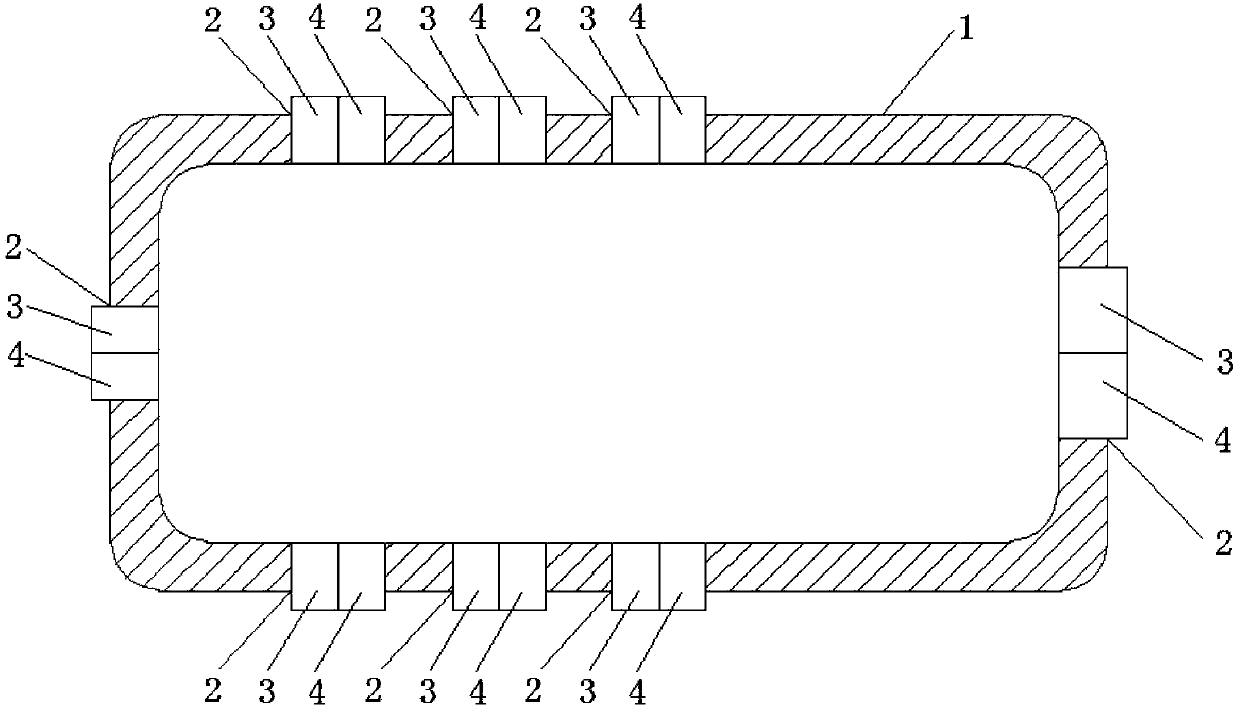

[0030] see figure 1 As shown, a mobile terminal with a middle frame of an antenna structure includes a body and a middle frame surrounding the body, the middle frame includes a middle frame body 1, and the middle frame body is provided with mounting holes 2. The integrated functional device 3 and antenna structure 4 are installed in the installation hole, and the integrated functional device and antenna structure are electrically connected to the circuit board arranged in the body. The antenna structure includes an antenna module, and the antenna module is electrically connected to a signal processor provided on the circuit board. The specific structures of the circuit board, the antenna module and the signal processor are not shown in the figure, and they are existing known technologies, so they will not be repeated here. The integrated middle frame body is made by integral injection molding of amorphous metal. At least one antenna structure is also provided on the partitio...

Embodiment 2

[0036] Embodiment 2. This embodiment is improved on the basis of Embodiment 1. The content described in Embodiment 1 is also included in this embodiment, and will not be repeated here.

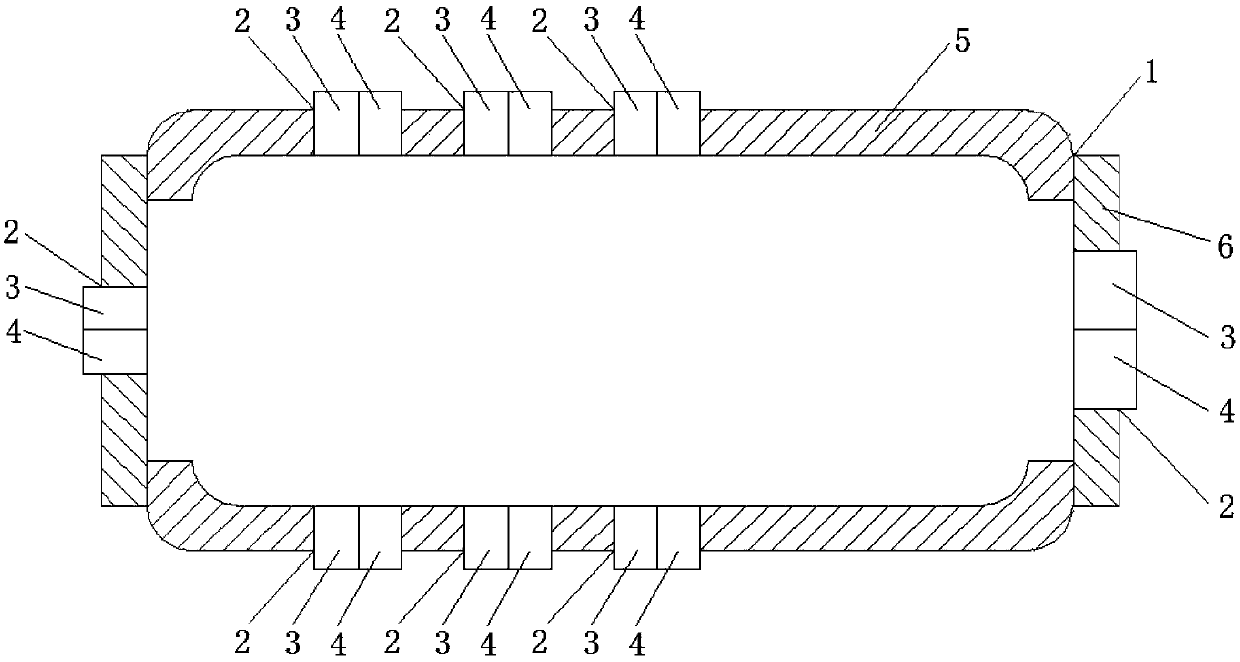

[0037] see figure 2 As shown, the difference from Embodiment 1 is that the middle frame body includes a non-partition frame 5 and a partition frame 6, and the non-partition frame and the partition frame are connected by other processes such as nano-injection molding process, and the Both the partition frame and the partition frame are provided with the installation holes, and the installation holes are installed with functional devices and antenna structures integrated into one component, and the functional devices and antenna structures are integrated into one component It is electrically connected with the circuit board arranged in the body. The power of the antenna structure installed on the partition frame is not less than the power of the antenna structure mounted on the non-partition f...

Embodiment 3

[0040] Embodiment 3, this embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

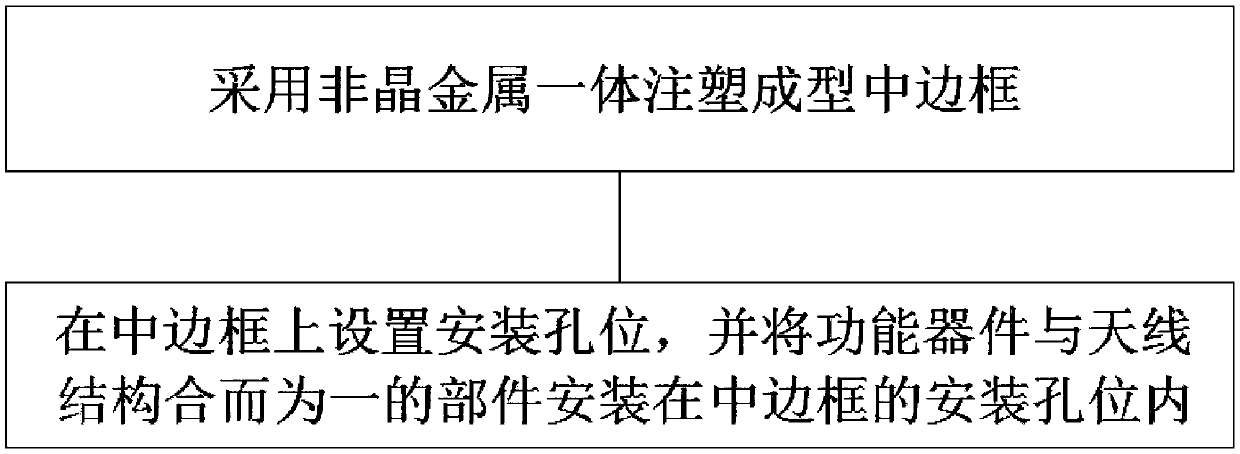

[0041] see image 3 Shown, a kind of manufacturing method of mobile terminal comprises the following steps:

[0042] The middle frame is integrally injection-molded with amorphous metal.

[0043] The manufacturing method of the mobile terminal also includes:

[0044] Mounting holes are provided on the middle frame, and components integrating the functional device and the antenna structure are installed in the mounting holes of the middle frame.

[0045] In the manufacturing method of the mobile terminal with the middle frame of the antenna structure described in this embodiment, a plurality of installation hole positions for installing the signal antenna are designed around the integrally formed metal middle frame. And the signal antenna is integrated with various components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com