Stirring device with adjustable stirring radius

A technology of stirring device and stirring radius, which is applied to mixers with rotating stirring devices, transportation and packaging, mixers, etc., can solve the problems of limited stirring range, simple structure, poor stirring effect, etc., and achieve good stirring effect, full mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

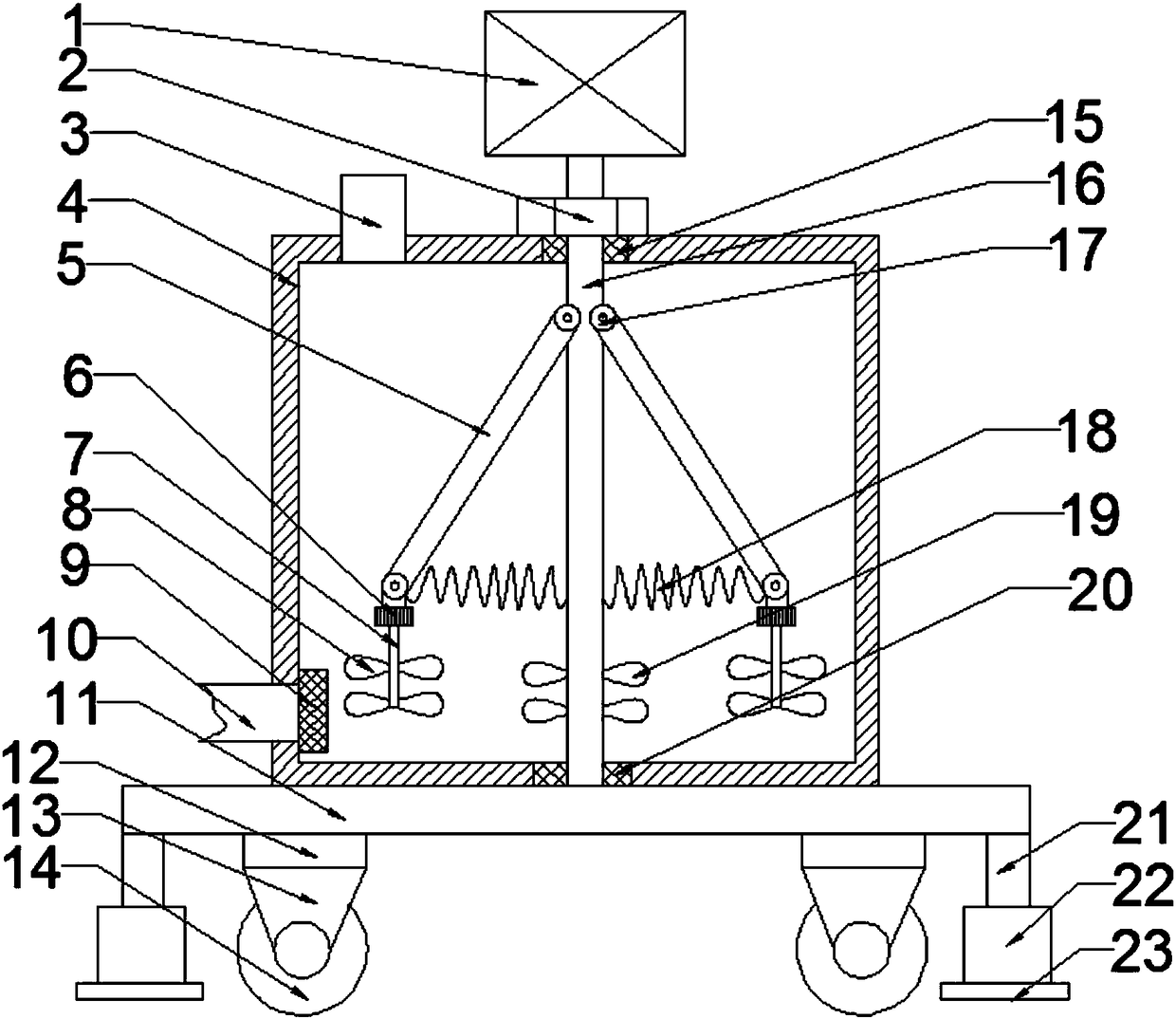

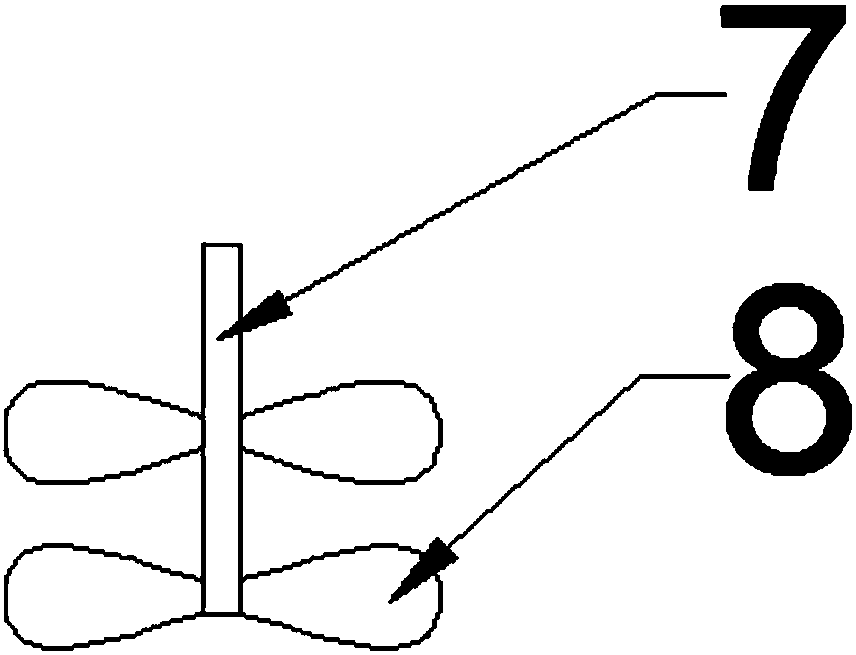

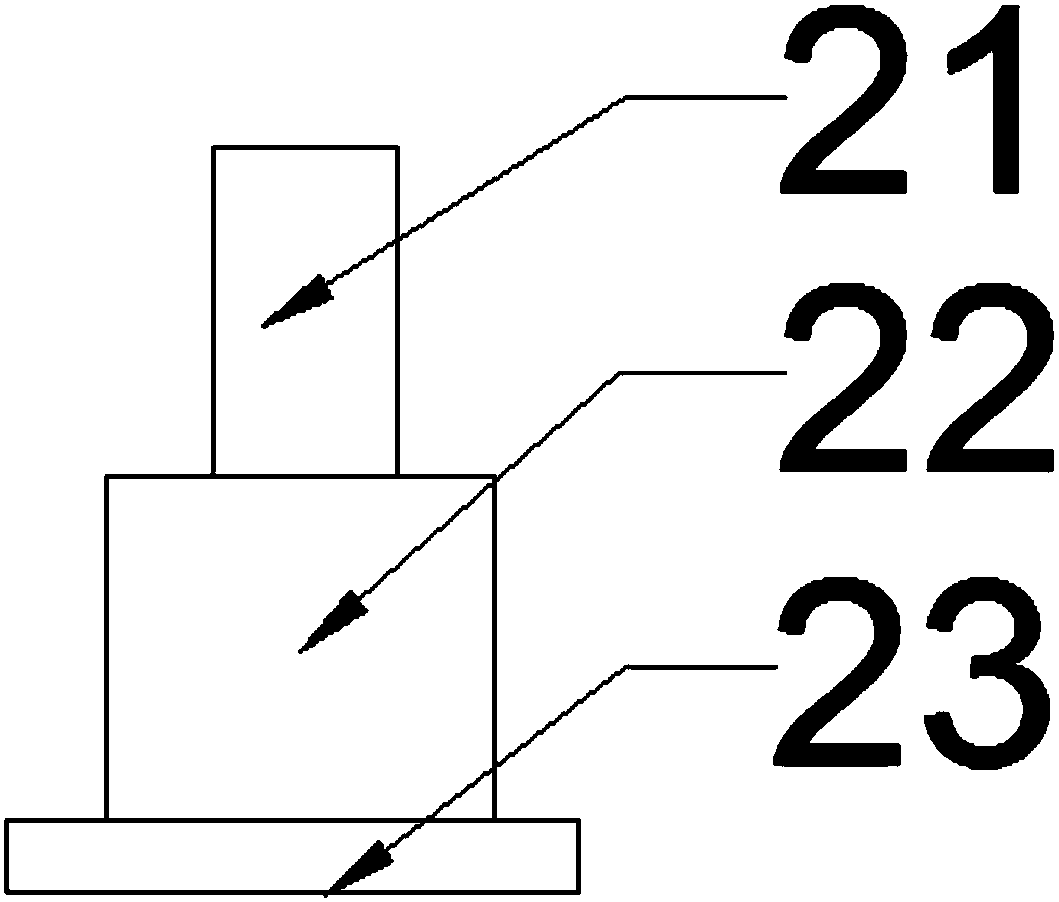

[0016] see Figure 1-3 , a stirring device with adjustable stirring radius, including a support device and a stirring device; the support device includes a base plate 11, a shock absorber 12, a wheel bracket 13, a wheel 14, a telescopic rod 21, a hydraulic cylinder 22 and an anchor 23; The four corners of the lower end surface of the base plate 11 are respectively provided with a hydraulic cylinder 22, and the hydraulic cylinder 22 is connected with the base plate 11 through a telescopic rod 21; the anchor 23 is fixedly arranged below the hydraulic cylinder 22, and the anchor 23 has the function of a stabilizing device; The shock absorber 12 is fixedly arranged on the lower end surface of the bottom plate 11 inside the telescopic rod 21, and the shock absorber 12 has the function of reducing the damage of the protection device while walking; Wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com