Steel cylinder shot blasting machine

A shot blasting machine and steel cylinder technology, which is applied to abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems that shot blasting machines cannot handle efficiently, and achieve the effects of improving shot blasting efficiency, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

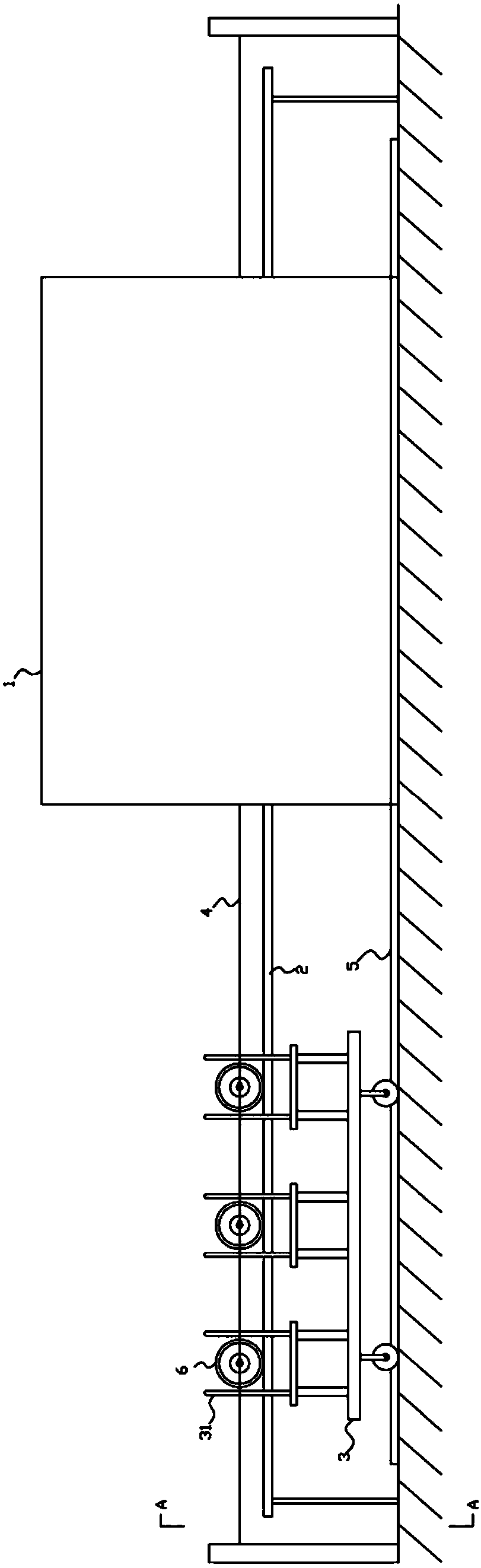

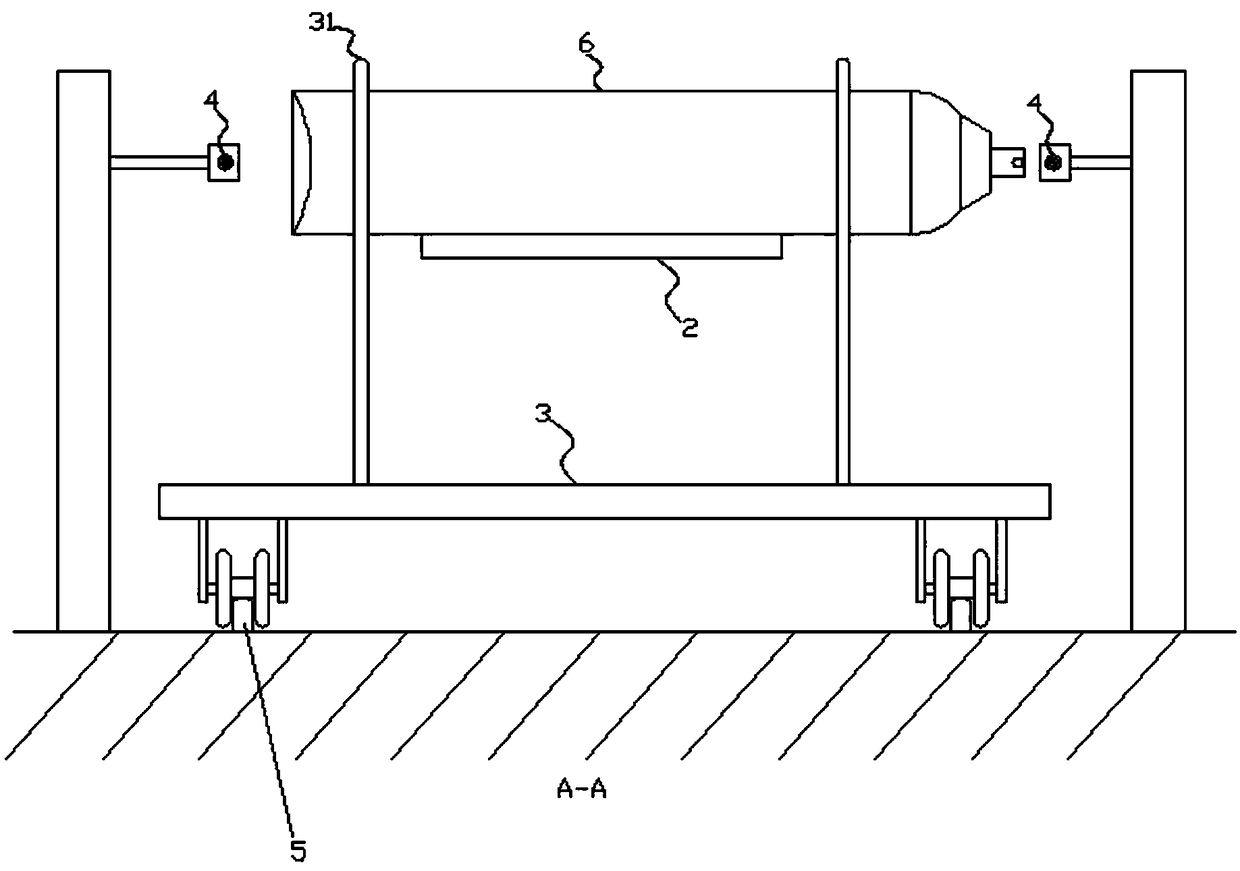

[0020] Such as figure 2 and image 3 As shown, the steel cylinder shot blasting machine of this embodiment includes a shot blasting chamber 1, a carrying platform 2, a traction trolley 3 and a protection steel rope 4;

[0021] The carrying platform 2 passes through the inside of the shot blasting chamber 1, such as Figure 4 and Figure 5 As shown, the carrying platform 2 is provided with a plurality of leak holes 21 with a square tapered cross section, and the leak holes 21 are used for the leakage of the pellets; a track 5 is installed below the carrying platform 2, and the track 5 is parallel to the carrying platform 2, and the traction trolley 3 The roller falls on track 5;

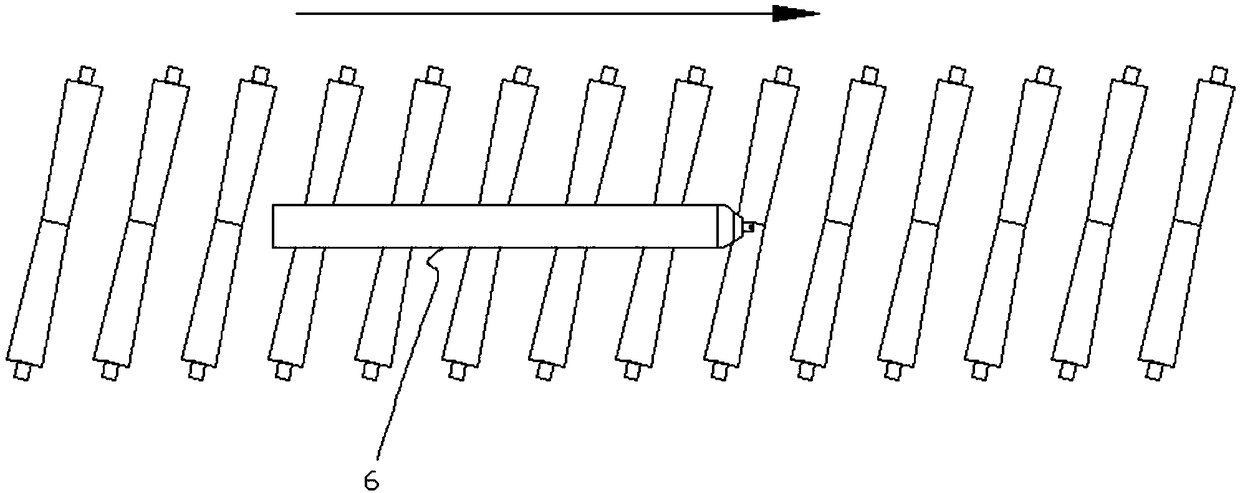

[0022] Three stations are arranged on the traction trolley 3, and each station includes four limit rods 31; Locate a steel cylinder 6; when the traction trolley 3 moves, the limit rod 31 drives the steel cylinder 6 to roll along the carrying platform 2;

[0023] Both sides of the bearing platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com