Cantilevered large-flying-wing unit type curtain wall system and installing method thereof

A unitary, flying-wing technology, applied in the field of exterior decorative curtain walls, can solve the problems of large impact on construction quality, complex procedures, slow construction progress, etc., and achieve the effect of reducing construction and installation procedures, ensuring appearance effects, and reducing overall costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to fully illustrate the technical means and creative features for realizing the present invention, the present invention will be further described below in conjunction with specific embodiments.

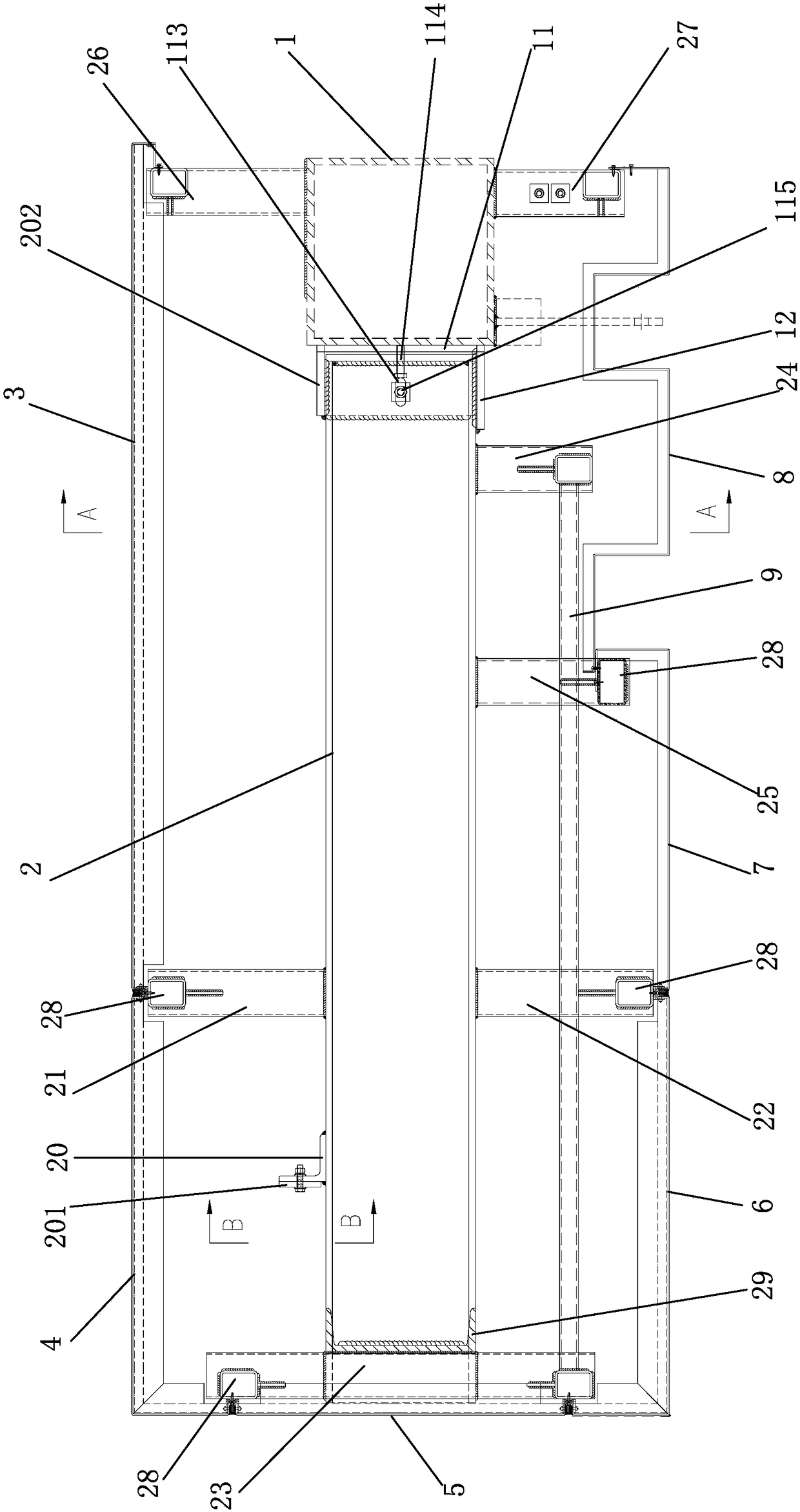

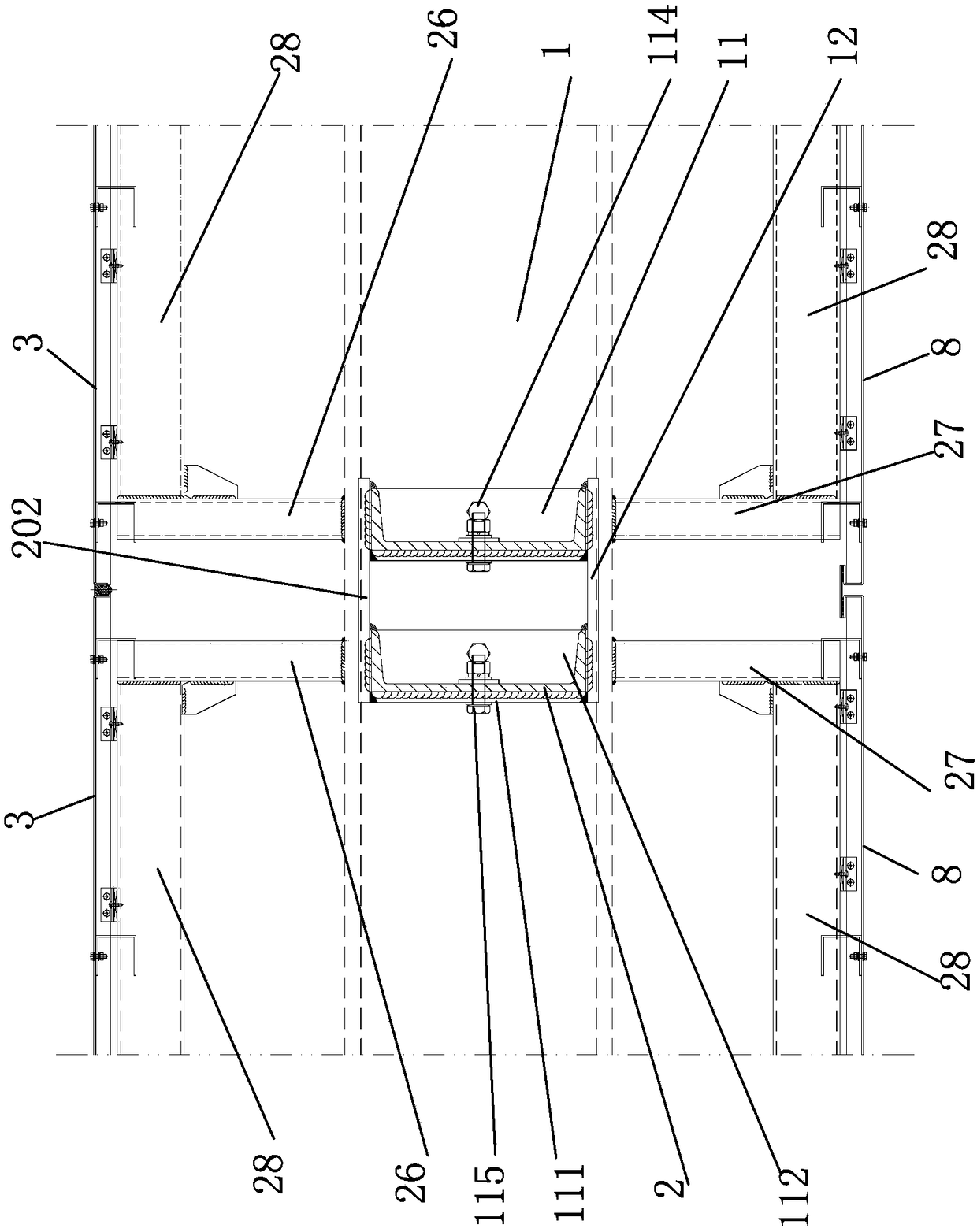

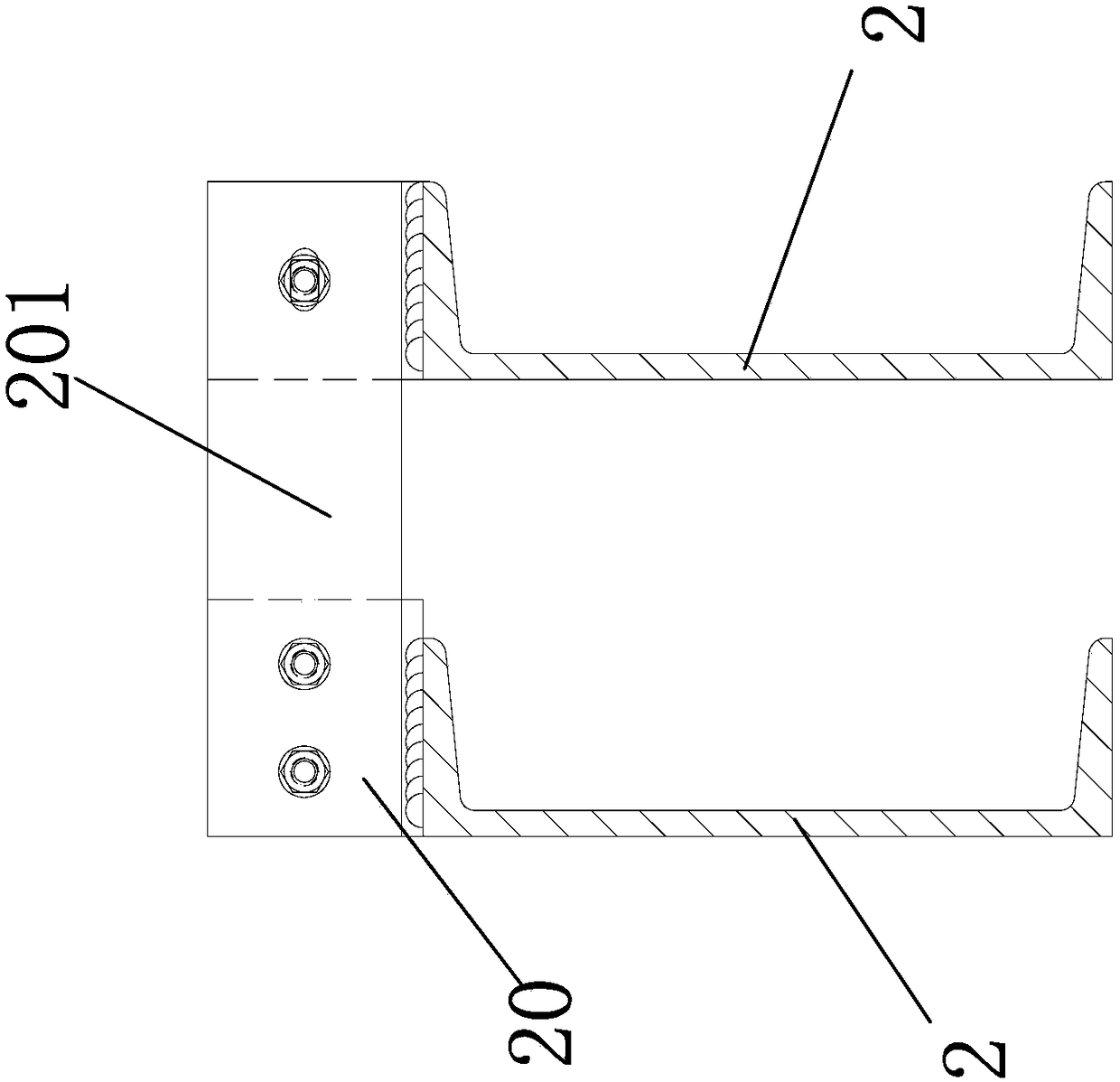

[0032] Such as Figure 1-Figure 3 As shown, the present invention provides a cantilevered large flying wing unit type curtain wall system, which includes a horizontal main body steel beam 1 fixed to the building main body and several flying wing units. The outer surface of the main body steel beam 1 is fixedly provided with several L-shaped connecting angle brackets 11 . The connecting angle bracket 11 has a first surface 111 and a second surface 112 perpendicular to each other, the first surface 111 is fixedly connected with the main body steel beam 1 , and the second surface 112 is provided with a horizontal adjusting slot 113 . The first surface 111 is fixedly connected to the main body beam 1 by connecting bolts 114 , and at the same time is fixedly connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com