Concrete construction vibrating device and construction method

A technology of vibrating device and construction method, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of large error in results and inability to intuitively reflect the compactness of artificially vibrated concrete, so as to reduce over-vibration. and under-vibration, reducing over-vibration and leakage, avoiding the effects of under-vibration and over-vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the description below, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

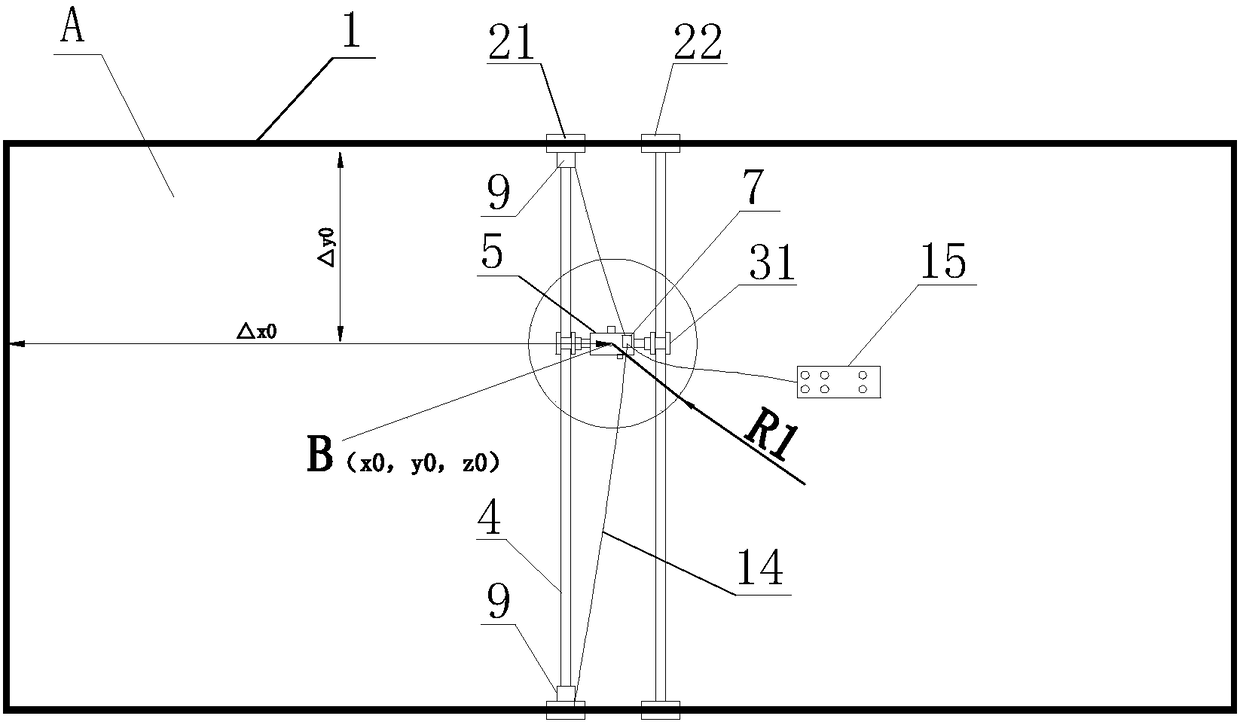

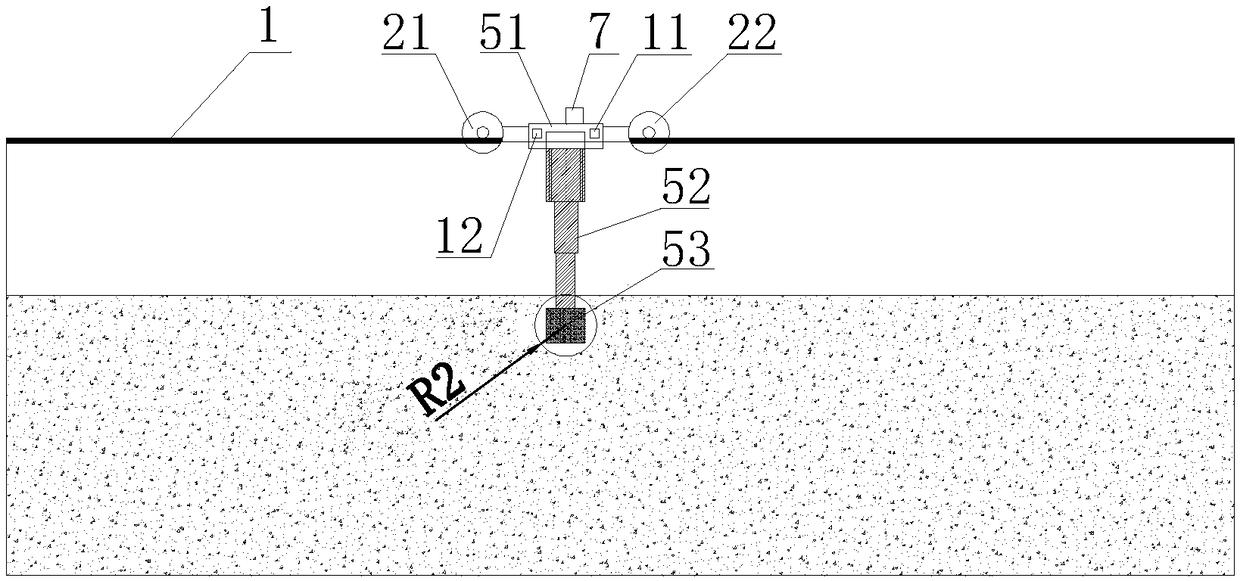

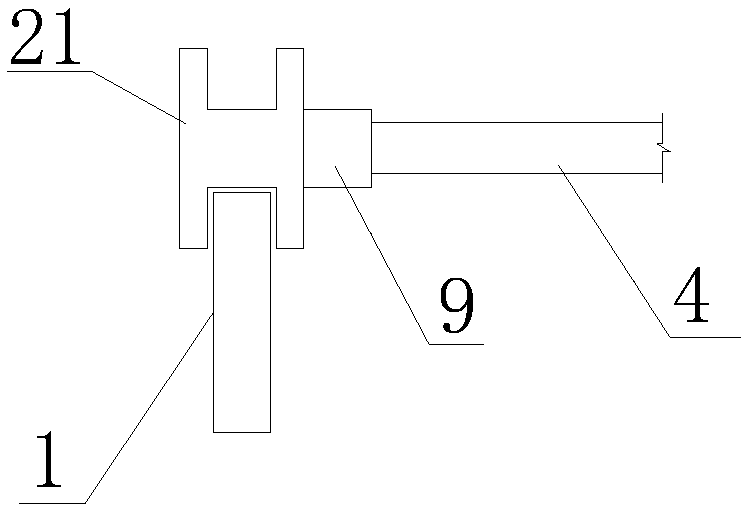

[0046] combine figure 1 , figure 2 shown and refer to Figure 7 , a vibrating device for concrete construction, comprising two transverse guide rails 1, longitudinal guide rails 4 appearing in pairs, a telescopic vibrating rod 5, a brake system 7 installed on the top of the telescopic vibrating rod 5, and a data acquisition card 8 and monitoring computer 10. Among them, two transverse guide rails are installed at the boundary position of construction area A. One of the longitudinal guide rails 4 is equipped with a driving wheel 21 controlled by a drive motor 9 at both ends, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com