Medium-temperature solar heat collecting tube suitable for industrial application and manufacturing method for medium-temperature solar heat collecting tube

A technology for solar collector tubes and industrial applications, applied in the field of medium-temperature solar collector tubes and manufacturing, which can solve the problems of short heating time of heat transfer medium, inability to make full use of the vacuum volume of all-glass vacuum heat collector tubes, and small heating area to achieve increased The effect of light-receiving and heat-absorbing area, increasing heat transfer path, and increasing heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

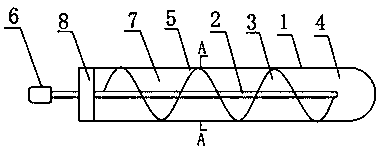

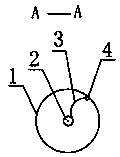

[0020] Such as figure 1 , 2 As shown, the medium-temperature solar heat collection tube includes an outer tube 1, a central tube 2 located in the outer tube 1, and a heat-absorbing plate 3 connected to the central tube 2 in a spiral shape. The outer tube 1 is a glass tube, and one end of the outer tube 1 is closed. The other end is open, and the open end is provided with an axially deformable metal end cap. The other side of the heat-absorbing plate 3 is also spirally connected with a peripheral pipe 4, and the central pipe 2 communicates with the peripheral pipe 4, that is, one end of the peripheral pipe 4 is connected to the bottom end of the central pipe 2, and the peripheral pipe 4 The other end is connected to the central tube 2 at the central tube 2 and the metal end cover 8, the central tube 2 and the peripheral tube 4 are copper tubes, the central tube 2 and the peripheral tube 4 are provided with a heat transfer medium, and the inside of the outer tube 1 is The vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com