An automatic cable plugging and unplugging device for mass centroid measurement

A technology for automatic plugging and measuring devices, which is applied in the direction of measuring devices, coupling devices, parts of connecting devices, etc., can solve the problems that small changes affect the accuracy of mass center of mass measurement results, improve accuracy and measurement efficiency, and improve work efficiency. Effects of improved efficiency, accuracy, and measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

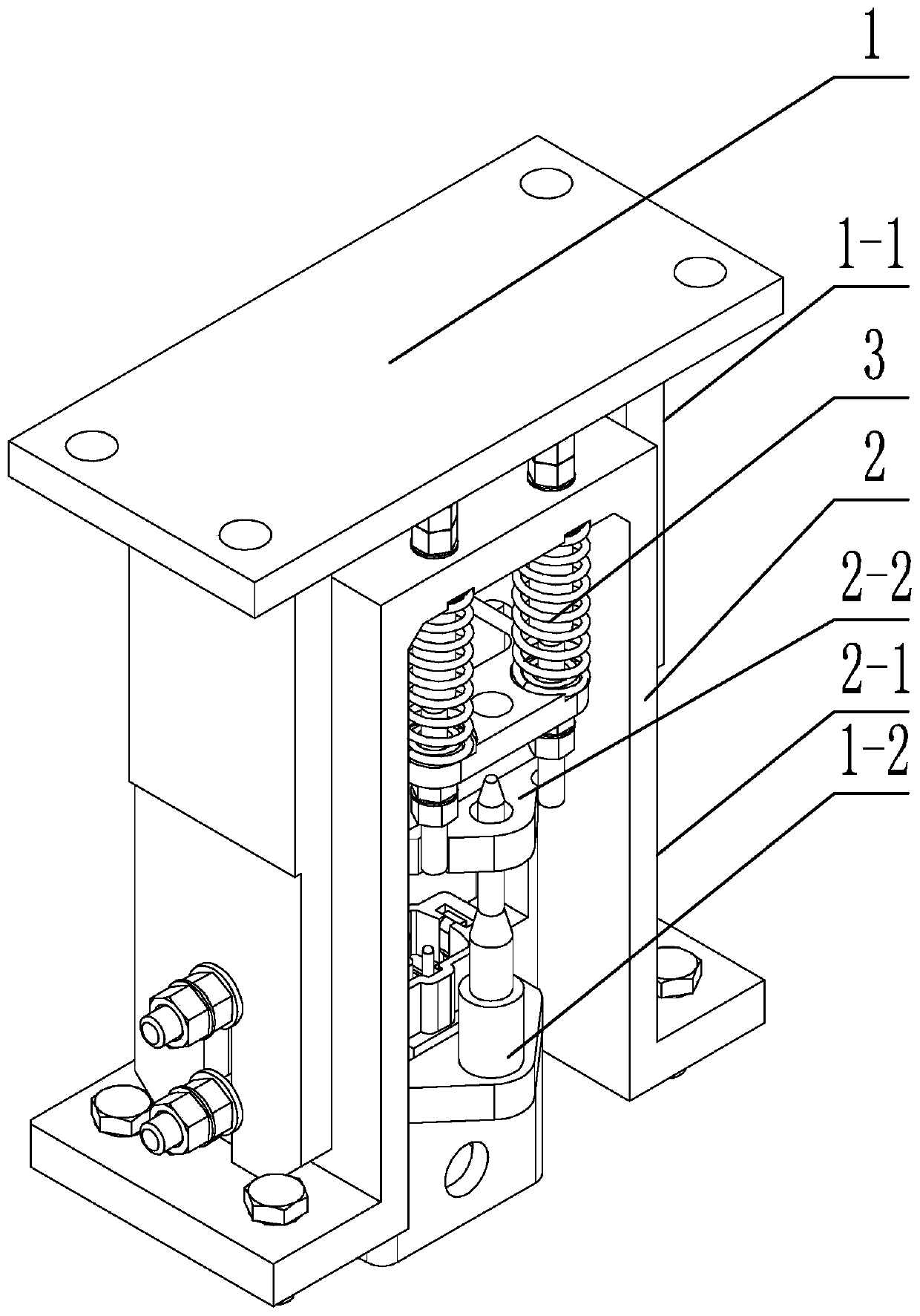

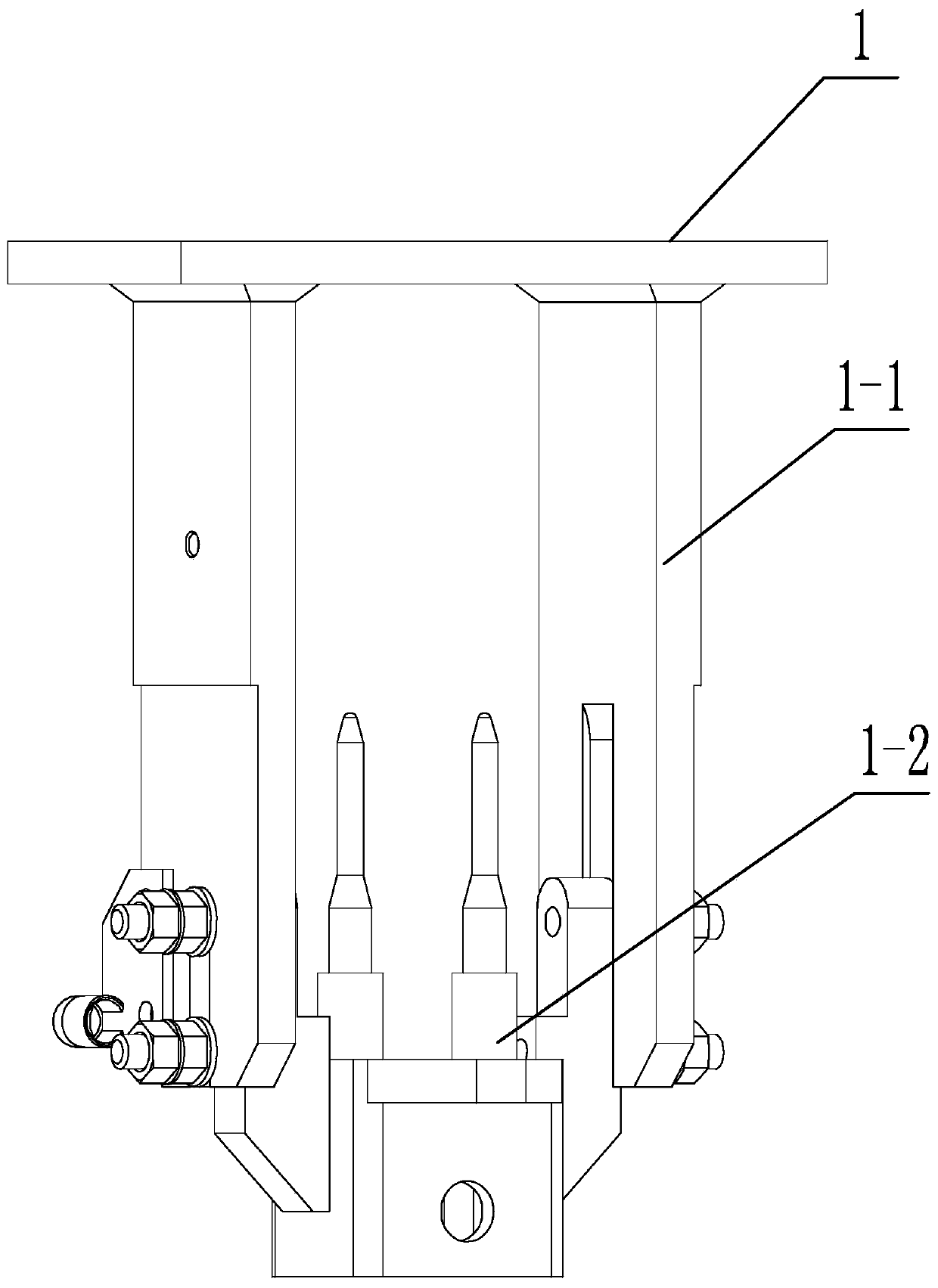

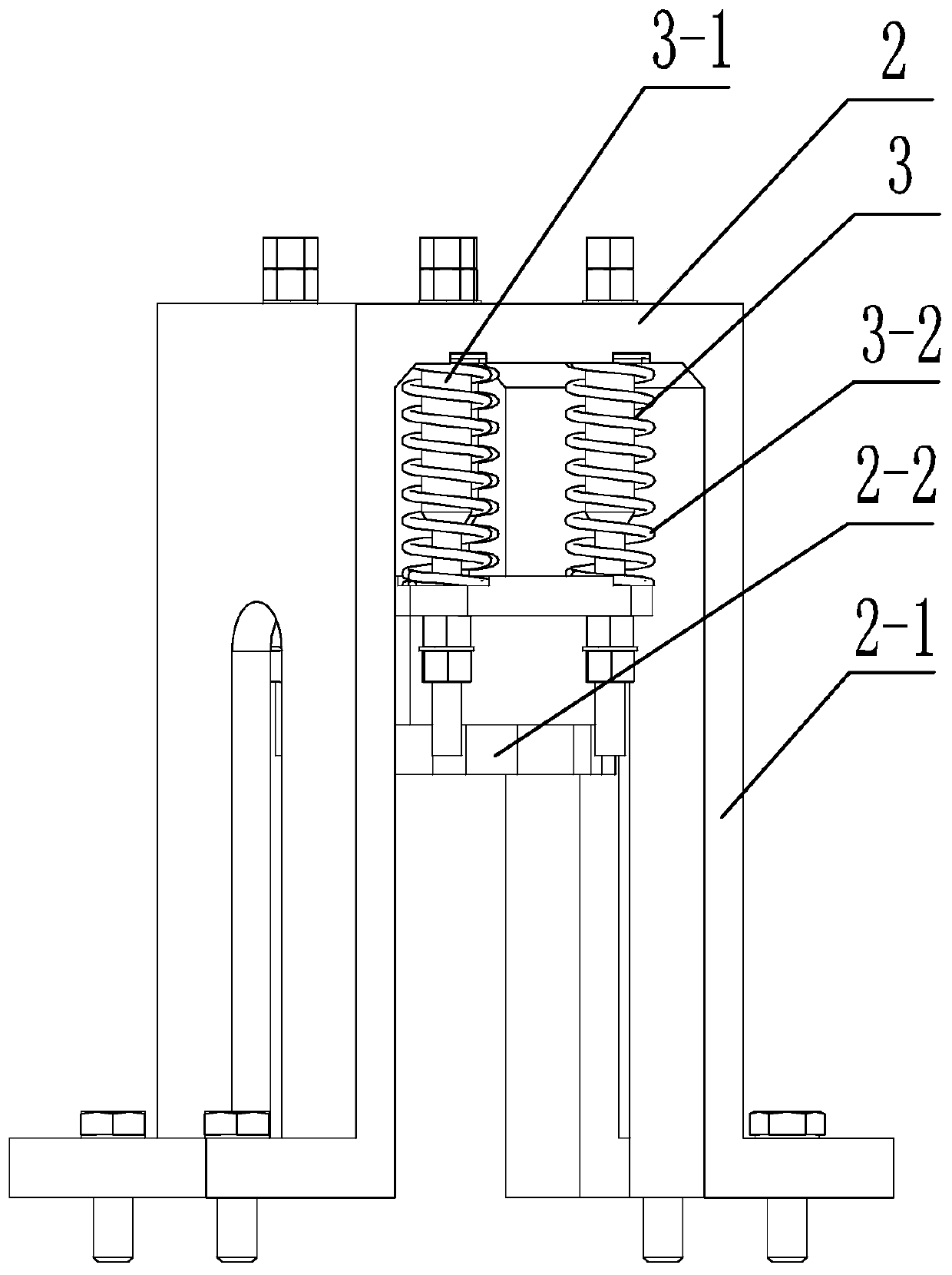

[0031] Specific implementation mode one: as Figure 1-5 As shown, the automatic cable insertion and removal device for mass centroid measurement in this embodiment includes an upper layer pin mechanism 1 and a lower layer jack mechanism 2. On the end face, the lower end face of the lower jack mechanism 2 is fixed on the upper end face of the bottom measuring device; the upper pin mechanism 1 includes a door-shaped fixing seat 1-1 and a pin fixing seat 1-2, and the pin fixing seat 1- 2 is installed on the bottom of the door-shaped fixed seat 1-1, the lower socket mechanism 2 includes the socket mounting seat 2-1, the elastic mechanism 3 and the cable socket 2-2, and the cable socket 2-2 passes through the elastic mechanism 3 Installed on the upper part of the socket mounting base 2-1, when the upper tooling falls to the lowest point, the pins of the pin holder 1-2 are separated from the cable jack 2-2, and when the upper tooling rises to the highest point, The pins of the pin ...

specific Embodiment approach 2

[0034] Specific implementation mode two: as figure 1 and figure 2 As shown, the upper end surface of the door-shaped fixing seat 1-1 in this embodiment is provided with an outer edge, and the outer edge of the door-shaped fixing seat 1-1 is fixedly integrated with the upper layer tooling of the mass centroid measuring device through four bolts. Such a design facilitates the installation of the gate-shaped fixing seat on the upper tooling of the mass centroid measuring device. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: as figure 1 and image 3 As shown, the outline of the socket mounting seat in this embodiment is in the shape of a "door", and the lower end of the socket mounting seat 2-1 is provided with an outer edge, and the outer edge of the socket mounting seat 2-1 passes through four bolts and the bottom measuring device Fixed as one. It is designed so that the socket mount can be easily installed on the bottom measuring device. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com