Alga filtration machine

A technology of modules and main pipes, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems that water purification equipment is difficult to meet basic requirements and different water requirements, so as to avoid cross-infection, stable filtration, and separation. The effect of water pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

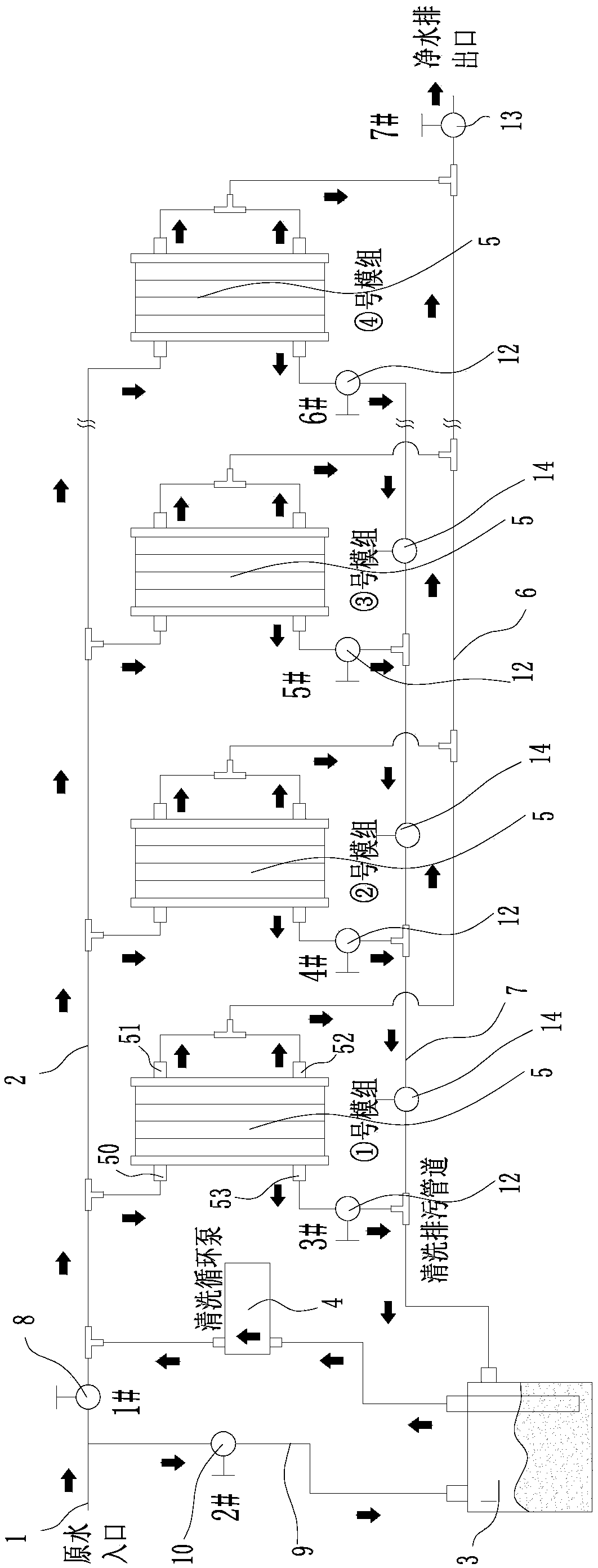

[0035] Algae filter, such as figure 1 As shown, it includes a raw water inlet 1, a raw water main pipeline 2, a water storage tank 3 providing circulating cleaning water or cleaning liquid, a cleaning circulation pump 4, four sets of algae filter modules 5, a main water purification pipeline 6 and a cleaning sewage pipeline 7, The water storage tank 3 mainly provides circular cleaning, and the liquid inside the water storage tank 3 can increase the cleaning liquid, and it is possible to choose whether to heat and keep the temperature of the internal liquid according to the demand; wherein, the raw water flowing into the raw water inlet 1 can be tap water or rough water. The water after level treatment; the pipeline between the raw water inlet 1 and the raw water main pipeline 2 is provided with a first switch control valve 8 for controlling the supply of tap water; each group of algae filter modules 5 is respectively provided with a raw water inlet 50, Two clean water outlets ...

Embodiment 2

[0053] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the two water purification outlets (51, 52) of each group of algae filter modules 5 are respectively connected to a main water purification pipe 6 to discharge the water respectively, The end of each clean water main pipeline 6 is also respectively provided with a clean water switch control valve 13 for controlling whether each clean water is discharged.

Embodiment 3

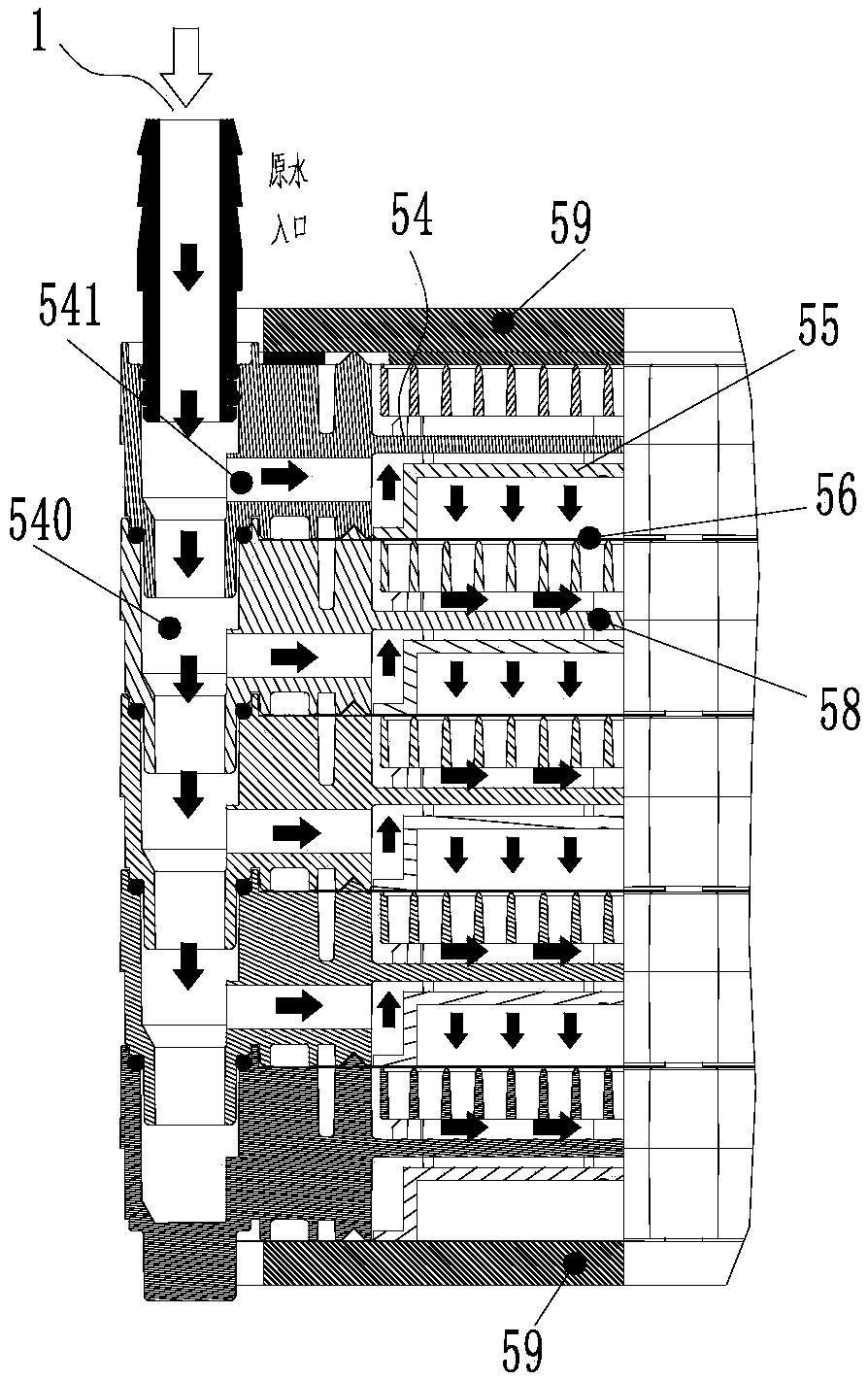

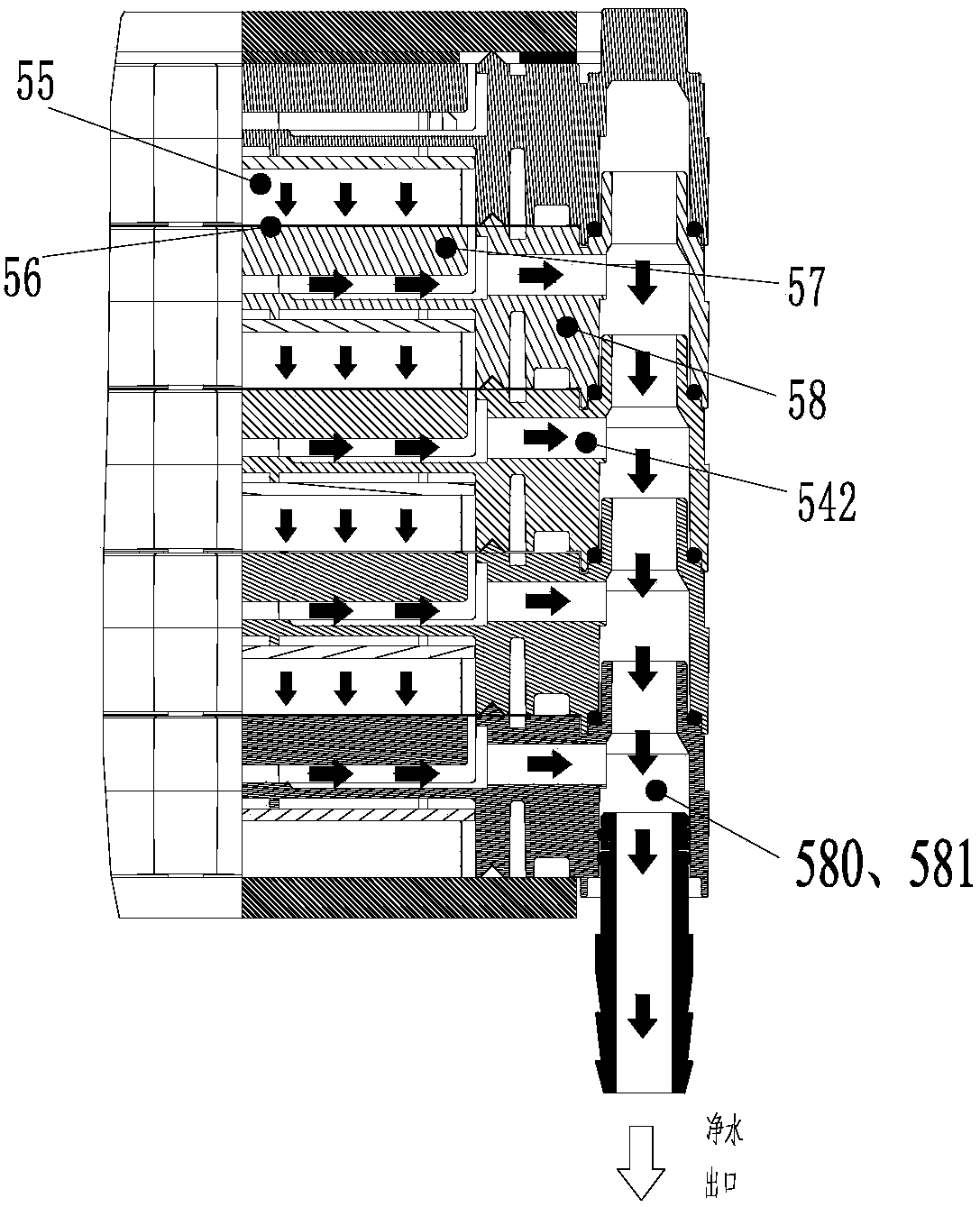

[0055] Such as Figure 7 and Figure 8 As shown, the difference between this embodiment and the first embodiment is that multiple groups of superimposed and combined raw water main pipe joints 540 and clean water main pipe joints (580, 581 ) and the end of the sewage pipe joint 582 are respectively provided with a one-way closed pipeline pipe plug 60; of course, according to the needs of the water inlet or water outlet position, the pipe plug 60 can also be arranged on the raw water main pipe joint 540, the water purification main The initial ends of the pipe joints (580, 581) and the sewage pipe joint 582 are correspondingly fed from the other side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com