Singeing device for textile

A textile and capillary technology, applied in the field of singeing devices for textiles, can solve the problems of fabric surface scald damage, fabric scrapping, easy to burn to the surface of the fabric, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

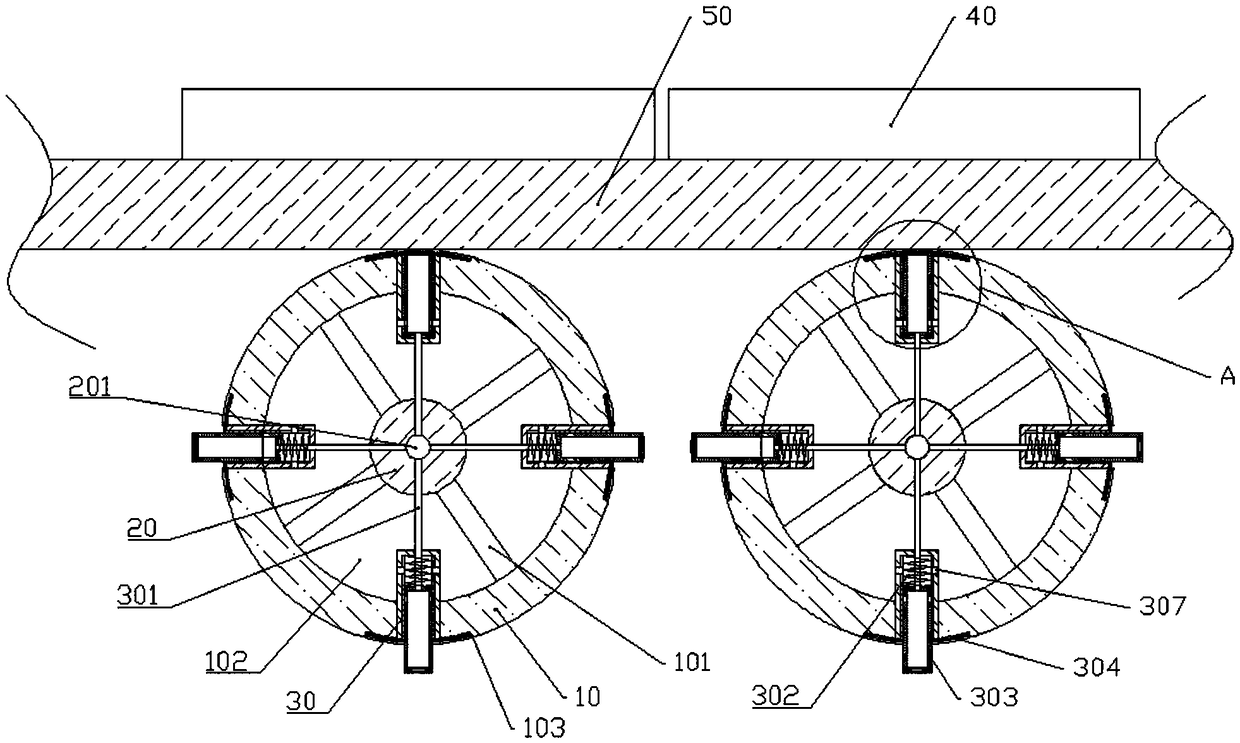

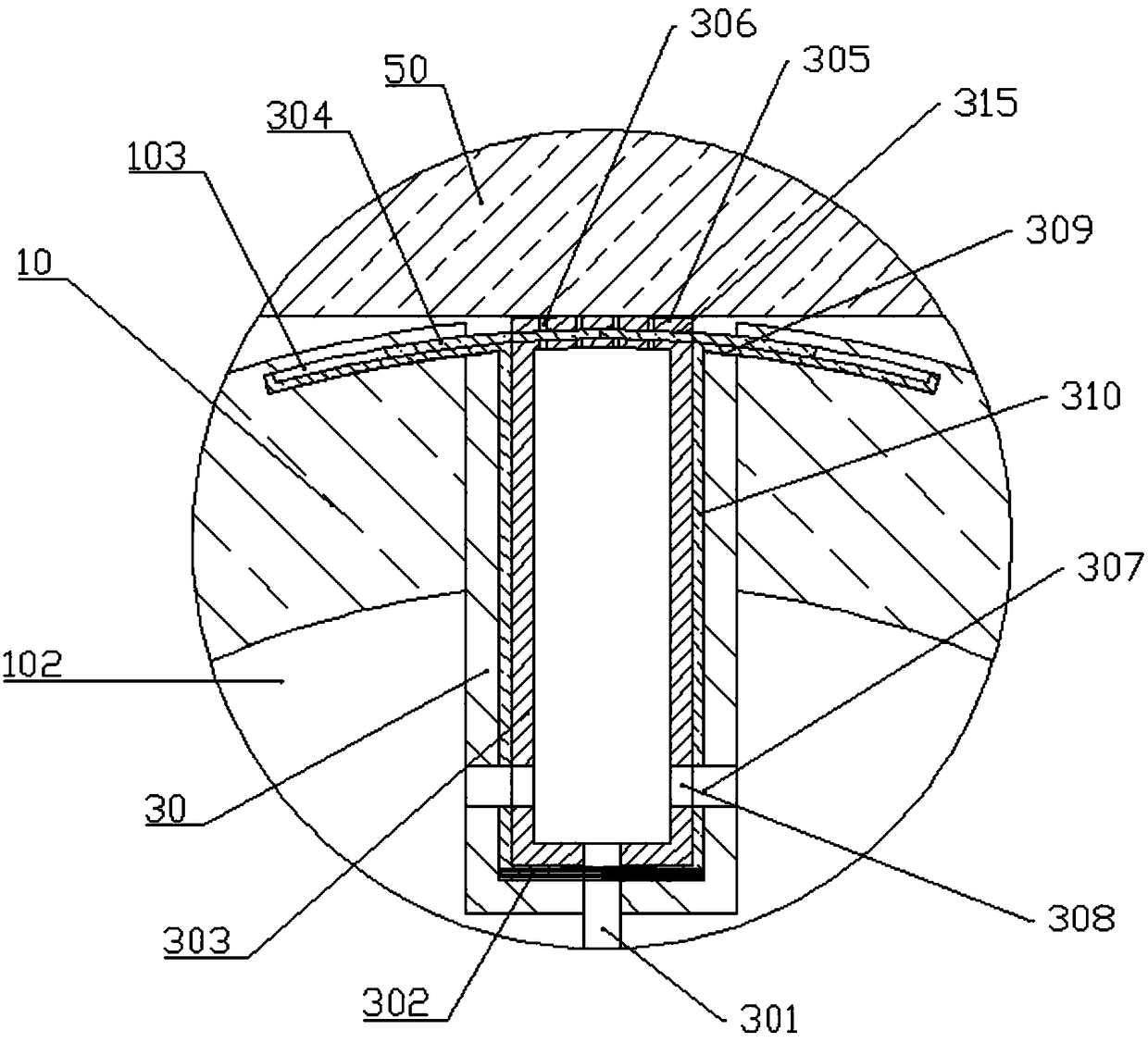

[0019] The reference signs in the drawings of the description include: drum 10, support rod 101, steam chamber 102, first chute 103, rotating shaft 20, negative pressure chamber 201, installation box 30, communication pipe 301, spring 302, hair suction pipe 303, Heating wire 304 , hair suction plate 305 , third chute 315 , first through hole 306 , second through hole 307 , third through hole 308 , second chute 309 , pull bar 310 , pressing plate 40 , fabric 50 .

[0020] The embodiment is basically as attached figure 1 And attached figure 2 Shown: the singeing device for textiles, including a drum 10, a rotating shaft 20, four singeing units and four suction units, the rotating shaft 20 is coaxially arranged in the drum 10, and four support rods are arranged between the drum 10 and the rotating shaft 20 101, the support rods 101 are all welded with the drum 10 and the rotating shaft 20, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com