Adjustable temperature limiting ring and temperature adjusting structure comprising same

An adjustable, temperature-limiting technology, applied to the valve housing structure, the device to prevent accidental or unauthorized action, the valve operation/release device, etc., can solve the difference, some are 42 ℃, some are 45 ℃ or 49 ℃, the overall pass rate of faucet products is low, and the faucet product inspection is unqualified, etc., to achieve the effect of good practicability, ingenious overall design, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

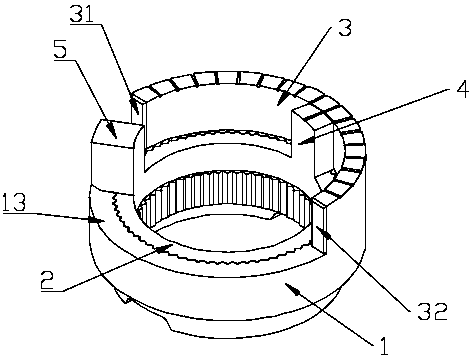

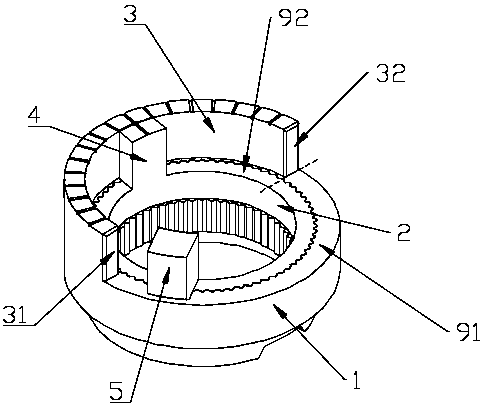

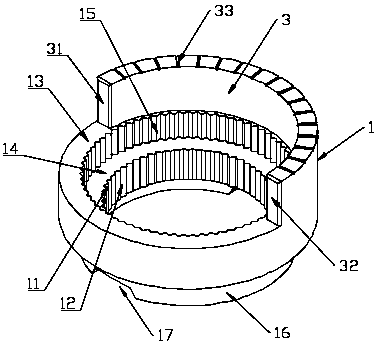

[0039] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0040] Such as Figure 8 , 9 , 10 is the temperature adjustment structure in the prior art, including the thermostatic valve core 6, the temperature adjustment handwheel 7, in order to avoid the excessive rotation of the temperature adjustment handwheel 7, the water temperature is too high so as to burn, between the thermostatic valve core 6 and the temperature adjustment handwheel 7 A temperature limiting ring 8 (also called a positioning ring) is set between the temperature handwheels 7 . The temperature adjustment hand wheel 7 rotates to drive the thermostatic valve core 6 to adjust the water temperature, and the temperature limiting ring 8 is used to limit the rotation range of the temperature adjustment hand wheel 7, thereby limiting the water temperature, so that the thermostatic valve core 6 can keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com