Load measurement system of rotation part in hinge structure

A technology of load measurement and parts, applied in the field of load measurement, can solve the problems such as the inability to measure the B load of the part, the lack of universal applicability of the load measurement method, and the low accuracy of the measurement results, so as to improve the scope of use and universal applicability. , the effect of less interference and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

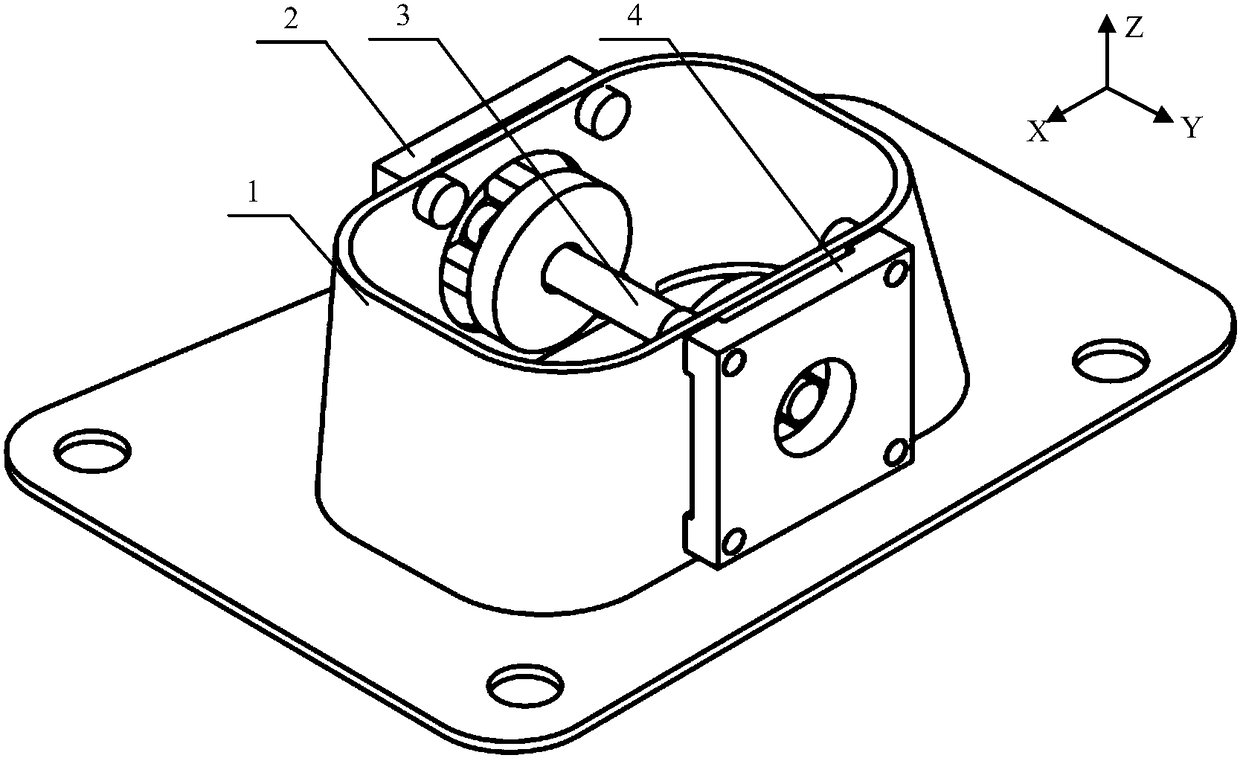

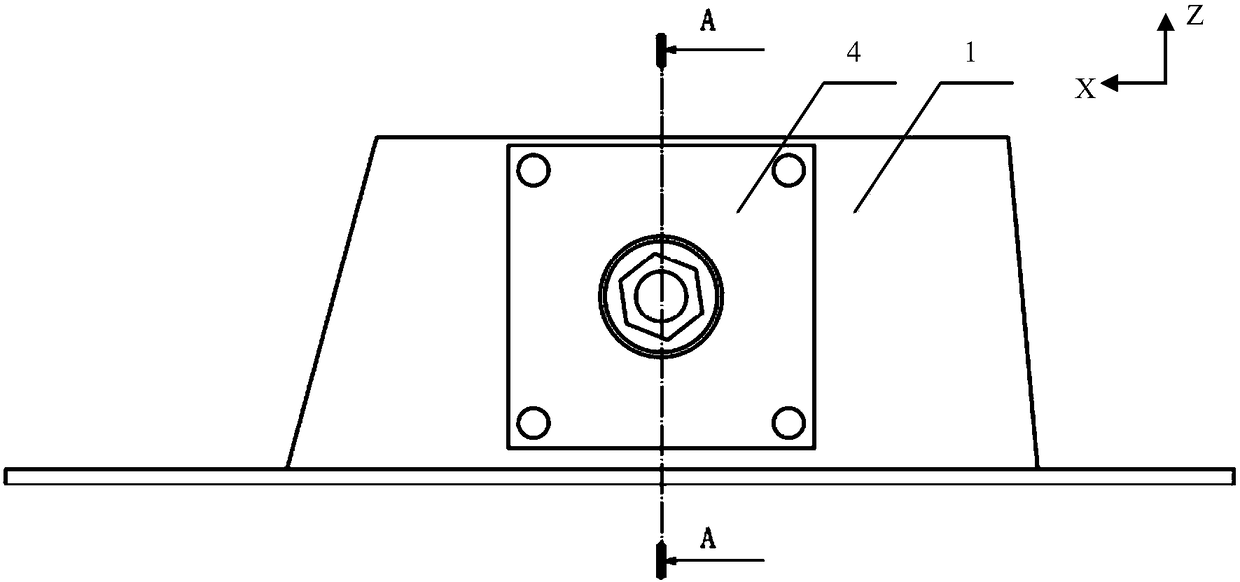

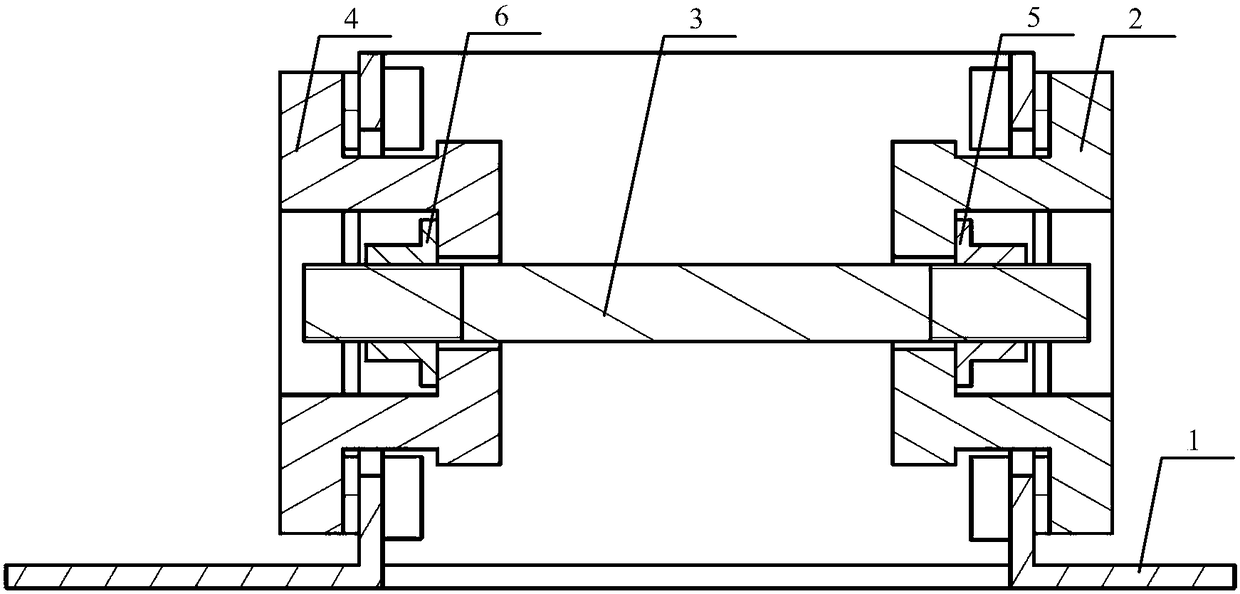

[0040] The connection points between vehicle chassis parts and the connection points between chassis parts and powertrain parts are widely used in hinged structures. Due to the compact structure of the chassis, the hinge point on the vehicle is usually reflected in two parts connected to each other. Suppose the two parts are part A and part B respectively, wherein: part A is the fixed end, and the hinge point of part A is located at Two metal plates arranged in parallel with a certain distance and processed with through holes. The hinge point of part B adopts a bushing structure, that is, there is a metal inner tube at the hinge point, and rubber and other materials are used to fill the space between the metal inner tube and the body of part B.

[0041] Part A and part B are clamped and connected by bolts to form a hinged structure. When working, part A and part B mainly transmit force through contact friction between each other, while the bolt basically does not bear shear f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com