On-line water suspended matter processor

A suspension and processor technology in water, which is applied in chemical instruments and methods, fixed filter element filters, filtration and separation, etc., can solve the problems of low processor efficiency, increased filter cleaning difficulty, and stuck between layers and other problems, to achieve the effect of easy implementation and application, high removal rate of suspended solids, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

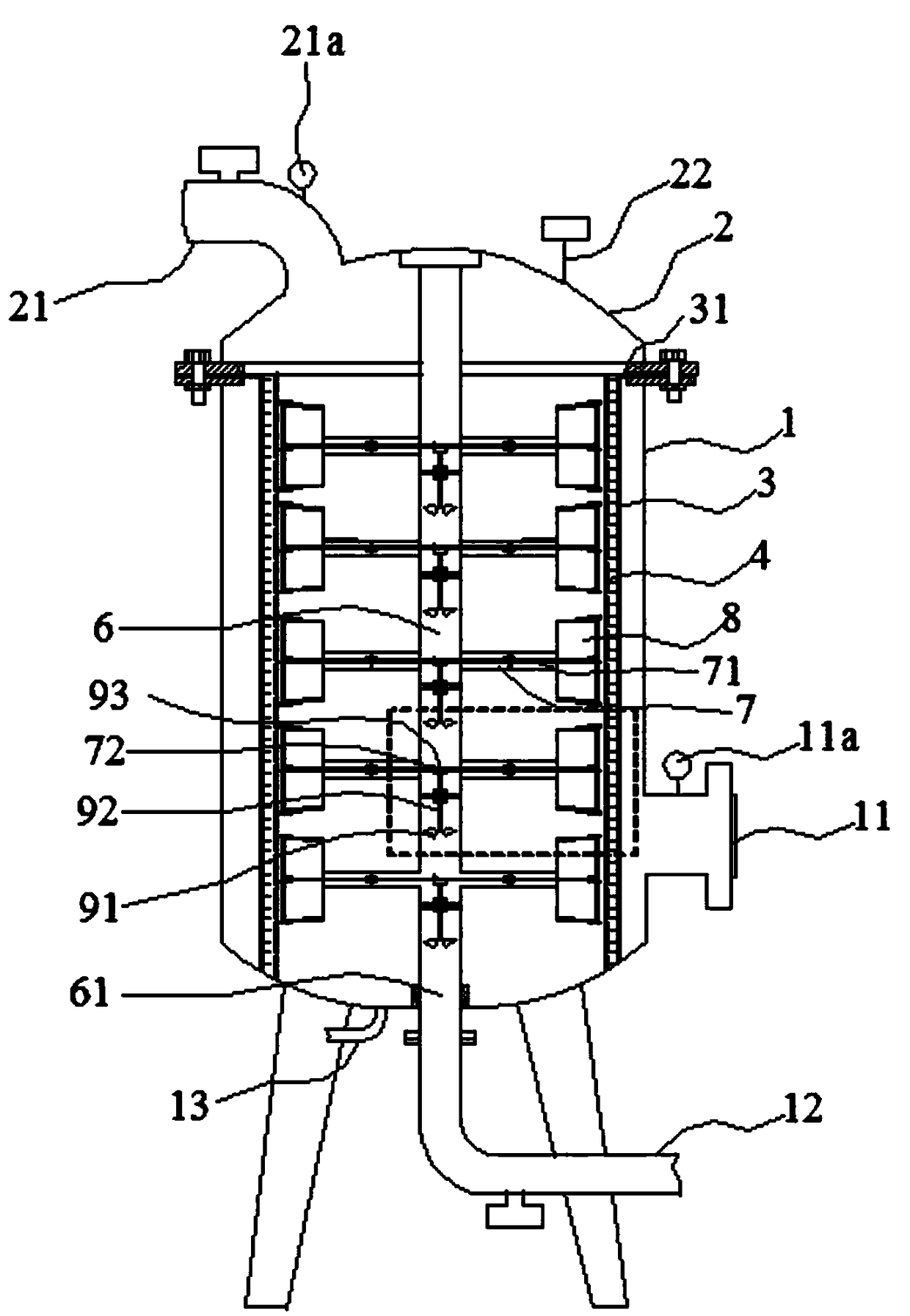

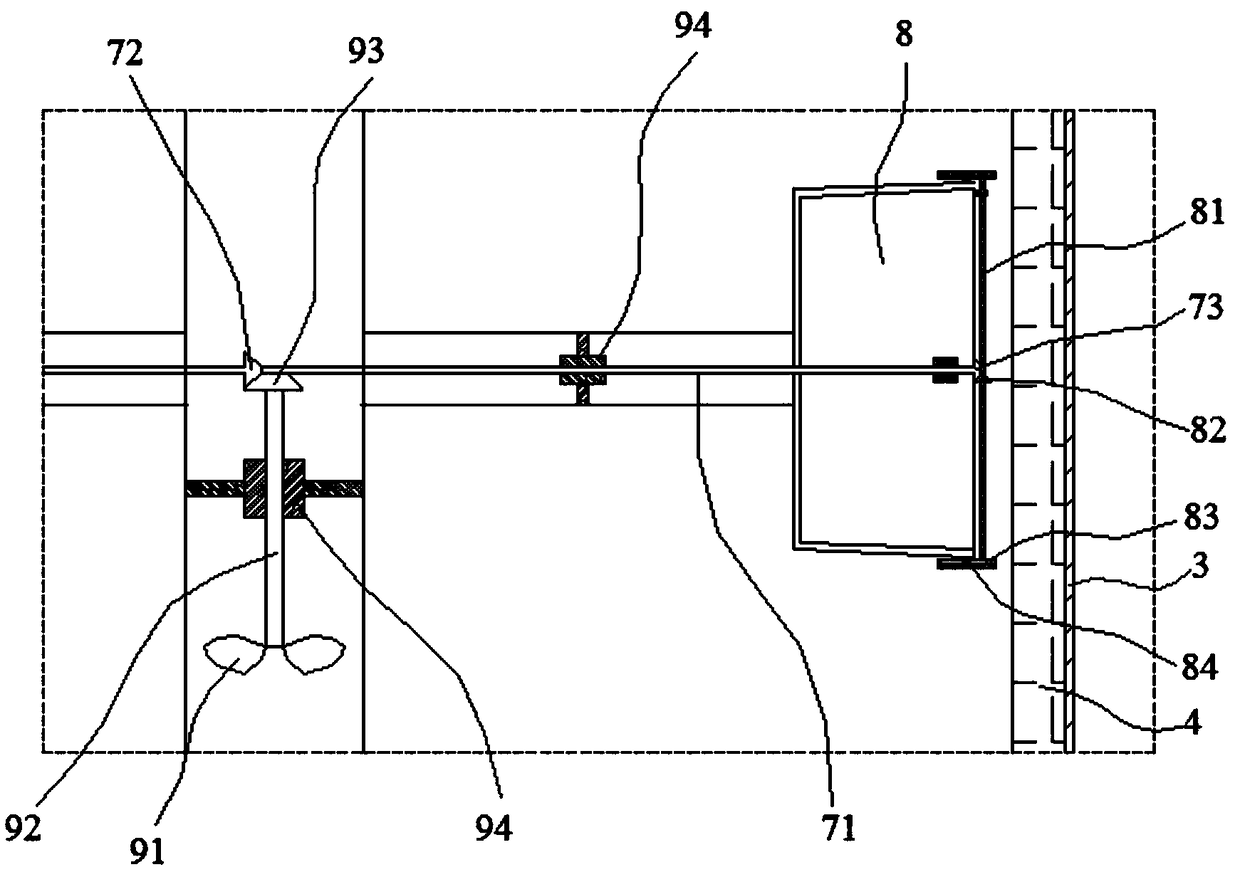

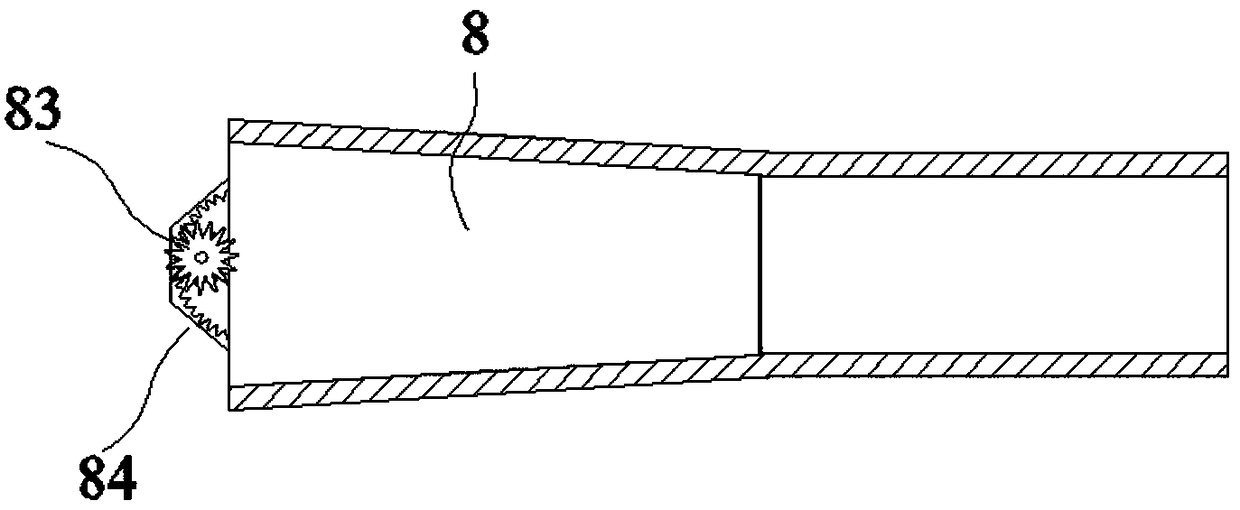

[0034] like Figure 1-3 As shown, this embodiment provides an online water suspended solids processor, comprising a tank body 1 with a water inlet 21 at the top, a water outlet 11 at the bottom, and a sewage outlet 12 at the bottom, and a filter set in the tank body 1. The net 4 also includes a sewage discharge rotating shaft 6 vertically inserted into the central position of the tank body 1. The sewage discharge rotating shaft 6 has a central through hole, and the bottom end 61 of the central through hole communicates with the sewage outlet 12, and the central axis of the central through hole is set There are several first transmission shafts 92, each first transmission shaft 92 passes through a bearing 94 fixed to the inner wall of the sewage shaft 6, and the lower end is provided with a fan blade 91, and the upper end is provided with a first bevel tooth 93; the filter screen 4 is Cylindrical and distributed around the sewage discharge shaft 6; moreover, on the side wall of...

Embodiment 2

[0036] like Figure 1-4 As shown, this embodiment provides an online water suspended solids processor, comprising a tank body 1 with a water inlet 21 at the top, a water outlet 11 at the bottom, and a sewage outlet 12 at the bottom, and a filter set in the tank body 1. The net 4 also includes a sewage discharge rotating shaft 6 vertically inserted into the central position of the tank body 1. The sewage discharge rotating shaft 6 has a central through hole, and the bottom end 61 of the central through hole communicates with the sewage outlet 12, and the central axis of the central through hole is set There are several first transmission shafts 92, each first transmission shaft 92 passes through a bearing 94 fixed to the inner wall of the sewage shaft 6, and the lower end is provided with a fan blade 91, and the upper end is provided with a first bevel tooth 93; the filter screen 4 is Cylindrical and distributed around the sewage discharge shaft 6; moreover, on the side wall of...

Embodiment 3

[0038] like Figure 1-3 As shown, this embodiment provides an online water suspended solids processor, comprising a tank body 1 with a water inlet 21 at the top, a water outlet 11 at the bottom, and a sewage outlet 12 at the bottom, and a filter set in the tank body 1. The net 4 also includes a sewage discharge rotating shaft 6 vertically inserted into the central position of the tank body 1. The sewage discharge rotating shaft 6 has a central through hole, and the bottom end 61 of the central through hole communicates with the sewage outlet 12, and the central axis of the central through hole is set There are several first transmission shafts 92, each first transmission shaft 92 passes through a bearing 94 fixed to the inner wall of the sewage shaft 6, and the lower end is provided with a fan blade 91, and the upper end is provided with a first bevel tooth 93; the filter screen 4 is Cylindrical and distributed around the sewage discharge shaft 6; moreover, on the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com