A reaction device and reaction method for catalytic dehydrogenation of alkanes

A reaction device and catalytic dehydrogenation technology, applied in chemical instruments and methods, dehydrogenation to hydrocarbons, organic chemistry, etc., can solve problems such as the complexity of the reaction regeneration system, and achieve the effect of eliminating potential safety hazards and avoiding flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of alkane dehydrogenation to olefins by using the above-mentioned reaction device for alkane dehydrogenation to olefins comprises the following steps, the raw material enters the reaction section from the feed distributor, and is contacted with the catalyst for catalytic reaction, wherein the raw material is upward in the reaction section The average linear velocity of the flow is controlled at 0.01-3.0m / s, the reaction temperature is controlled at 500-650°C, and the mass space time of the reaction is 0.1-15h.

[0067] In certain embodiments, the reaction temperature is controlled between 550°C and 620°C.

[0068] In certain embodiments, the mass space time of the reaction is 1-8 hours.

[0069] The pressure at the top of the settling section of the reaction device is controlled at -0.01 to 0.1 MPa, preferably 0 to 0.05 MPa (table).

[0070] In some embodiments, the superficial gas velocity in the riser is 1-20 m / s, preferably, 3-10 m / s.

[0071...

Embodiment 1

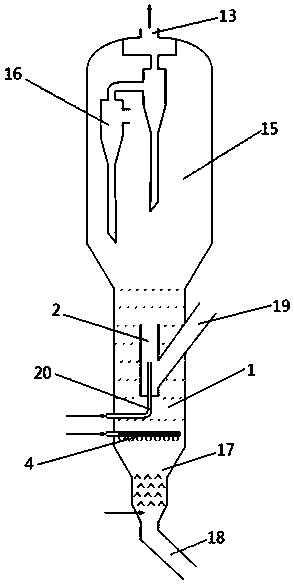

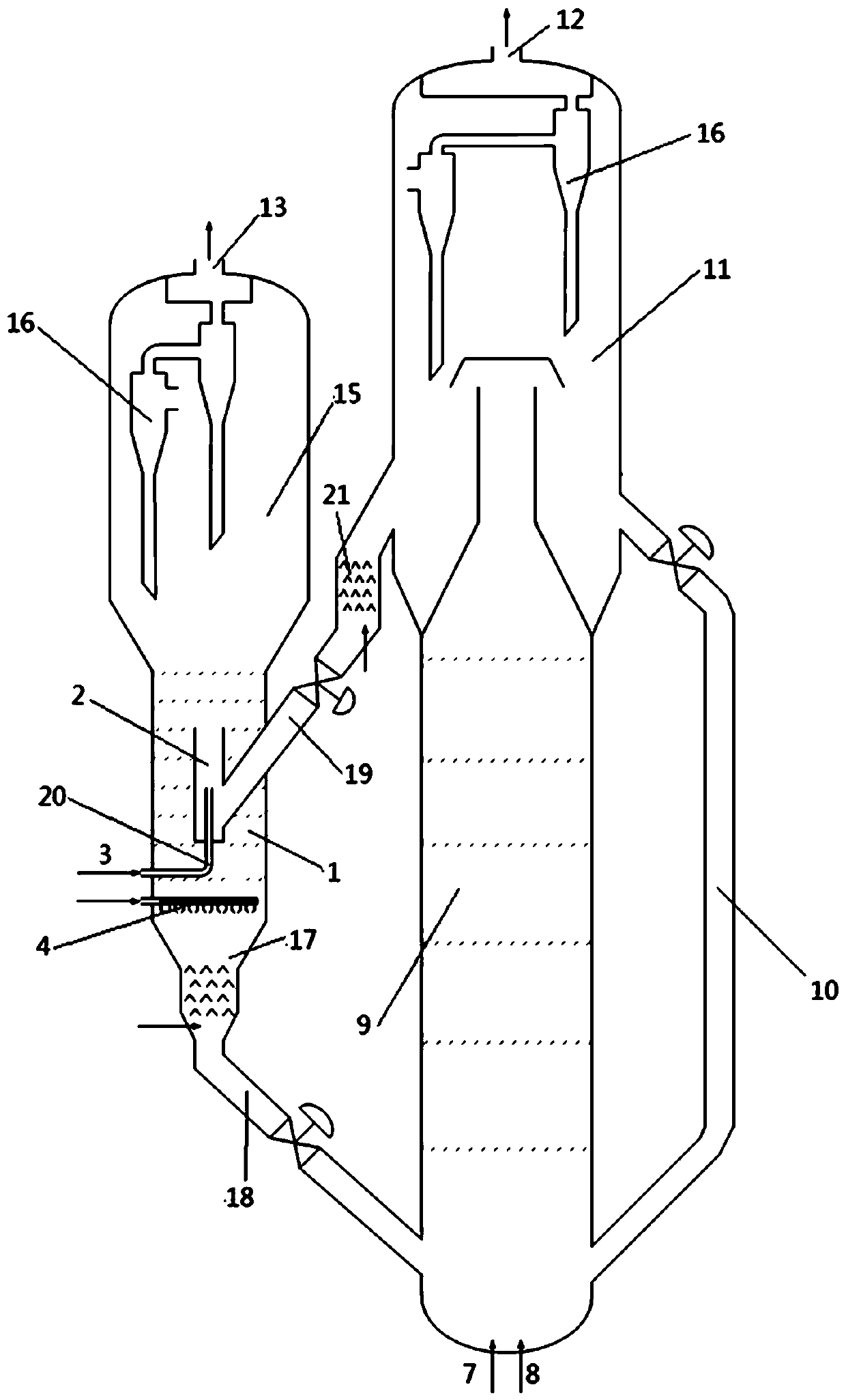

[0094] This embodiment refers to the attached figure 1 As shown, the reaction device for the catalytic dehydrogenation of alkanes provided in this application is used in combination with the catalyst regeneration device provided in this application. These two sets of devices can be used separately, and respectively used in combination with other reaction devices or catalyst regeneration devices in the prior art.

[0095] attached figure 1 The reaction device for the catalytic dehydrogenation of alkane comprises a reaction section 1 and a settling section 15, the settling section 15 is located on the top of the reaction section 1, the settling section 15 is an equal-diameter tank structure, and the reaction section 1 is an equal-diameter cylindrical structure. Section 1 has a smaller diameter than settling section 15 . The lower part of the reaction section 1 is a diameter-reducing section 17 (stripping section), which is connected with the inclined tube 18 for the catalyst t...

Embodiment 2

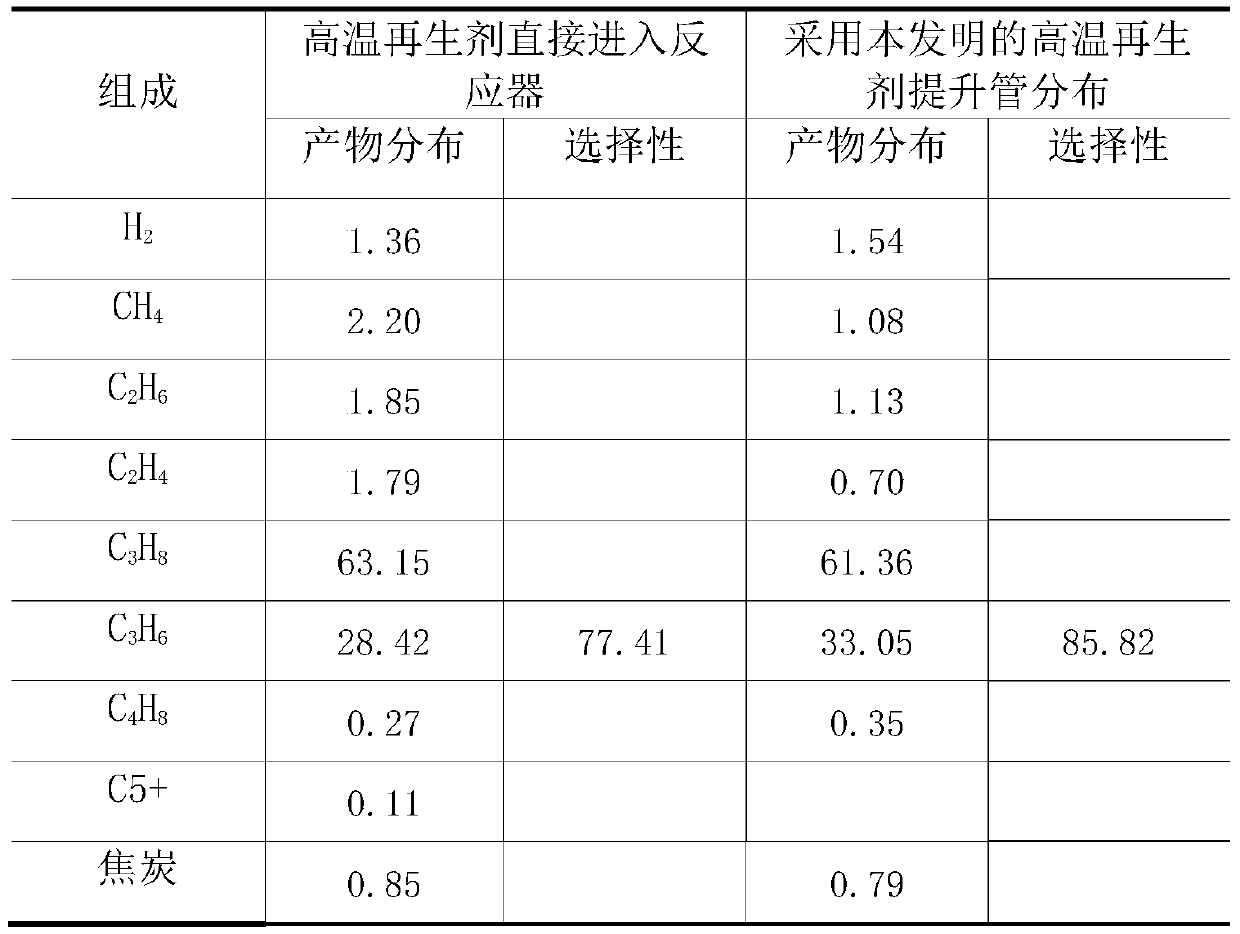

[0107] Propane dehydrogenation produces propylene, adopts the equipment of embodiment 1 of the present invention

[0108] Raw material: 99.87wt% propane, feed rate 0.5t / h

[0109] Catalyst: Environmentally friendly metal oxide catalyst ADHO-1 (ZL 2011 1012 3675.1)

[0110] Reaction conditions: the average temperature of the bed is 600°C; the pressure of the settler is 0.025MPa; the mass space time is 4h; the superficial gas velocity of the gas in the bed is 0.6m / s. The superficial gas velocity in the riser is 5m / s; the lifting medium is raw gas; the outlet of the riser is 2m away from the bed interface.

[0111] Regeneration conditions: Catalyst regeneration temperature, 700°C

[0112] The distribution mode of the high-temperature regenerant in the reactor: in the present invention, the distribution of the riser; in contrast, it directly enters the gas phase of the reactor

[0113] Table 1. Propane dehydrogenation product distribution and propylene selectivity with 99.87 wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com