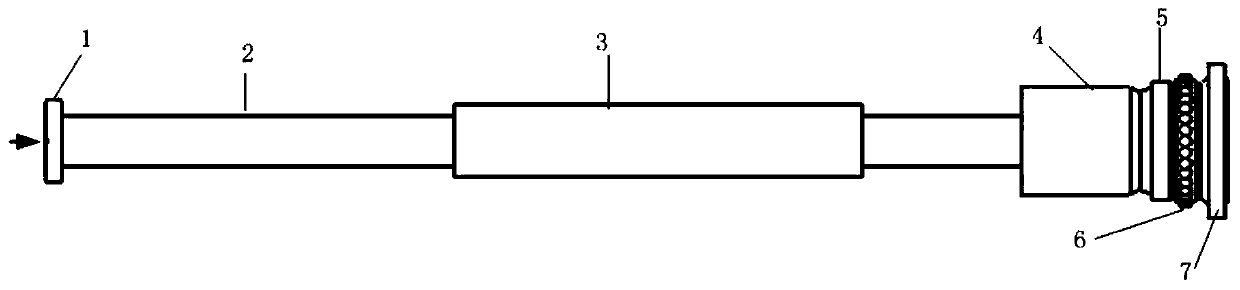

A three-axis free bending local progressive forming device and method

A technology of incremental forming and propulsion device, which is applied in the advanced manufacturing field of three-axis free bending partial incremental forming, can solve the problems of low forming quality, high production cost, low production efficiency, etc., and achieves simple and feasible method, improved efficiency, and flexible forming. great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the first step, put the H68 copper alloy tube with a length of 1170mm, a diameter of 15mm and a wall thickness of 1mm into the equipment, and push the tube blank forward by the push block;

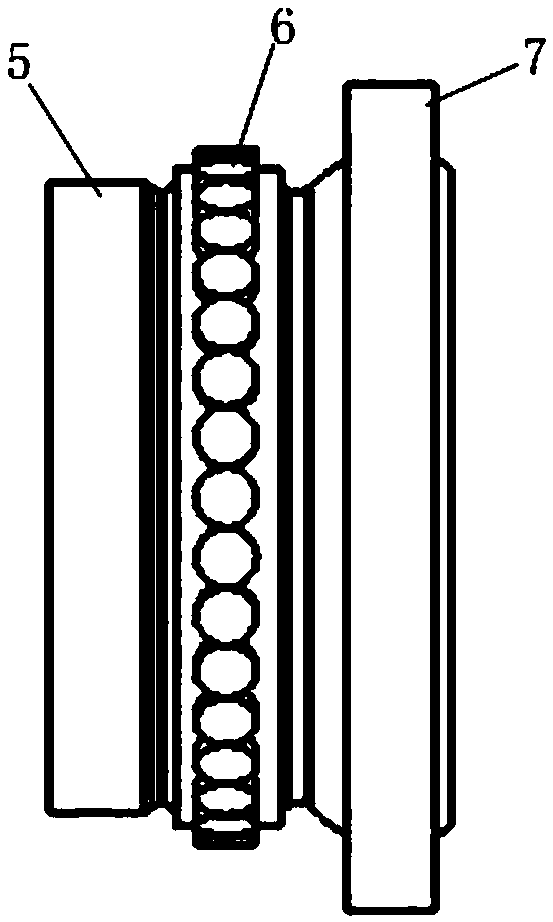

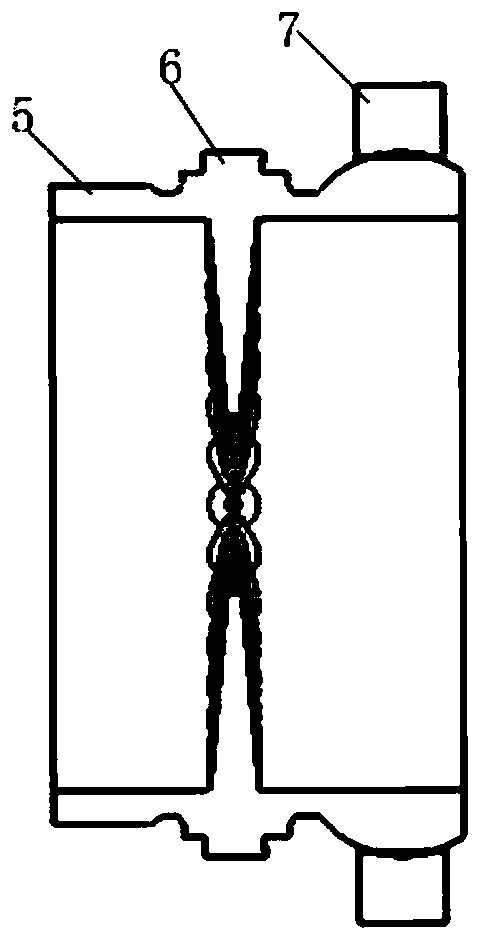

[0037] In the second step, the bending die is adjusted to a circular opening under the control of the system, and the opening diameter is 15.2mm;

[0038] In the third step, the spherical bearing moves from the initial position to the eccentric position with coordinates (0,10) on the motion plane, and then drives the bending die to move with a clockwise quarter-circle track to realize the three-dimensional free bending of the tube blank. bent into shape, and finally obtained as Figure 4 The complex curved hollow member shown.

[0039] The fourth step is to modify the parameters of the bending process to solve the problem of springback after bending by performing three-dimensional scanning on the bent hollow member and comparing it with the three-dimensional geometric model of t...

Embodiment 2

[0041] The first step is to put a 1060 aluminum alloy tube with a length of 1500mm, a diameter of 20mm, and a wall thickness of 2mm into the equipment, and push the tube blank forward by the push block;

[0042] In the second step, the bending die is adjusted to a circular opening under the control of the system, and the opening diameter is 20.2mm;

[0043] In the third step, the spherical bearing moves from the initial position to the eccentric position with coordinates (0,15) on the motion plane, and then drives the bending die to move with a counterclockwise half-circle track to realize the three-dimensional freedom of the tube blank. bent into shape, and finally obtained as Figure 5 The complex curved hollow member shown.

[0044] The fourth step is to modify the parameters of the bending process to solve the problem of springback after bending by performing three-dimensional scanning on the bent hollow member and comparing it with the three-dimensional geometric model o...

Embodiment 3

[0046]The first step is to put a 5754 aluminum alloy tube with a length of 1000mm, a diameter of 10mm and a wall thickness of 1mm into the equipment, and the push block pushes the tube blank forward;

[0047] In the second step, the bending die is adjusted to a locally convex shape under the control of the system.

[0048] In the third step, the spherical bearing moves from the initial position to the eccentric position with coordinates (0,-8) on the motion plane, and then drives the bending die with a counterclockwise one-third circular arc track to realize three-dimensional tube blank Free bending shape, and finally get such as Figure 6 A complex curved hollow member with grooves is shown.

[0049] The fourth step is to modify the parameters of the bending process to solve the problem of springback after bending by performing three-dimensional scanning on the bent hollow member and comparing it with the three-dimensional geometric model of the target product.

[0050] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com