Propeller casting forming solidification sequence control device and control step thereof

A control device and solidification sequence technology, which is applied in the field of solidification sequence control devices for propeller castings, can solve problems affecting the mechanical properties of castings, shrinkage porosity, pores, etc., and achieve the effects of reducing pouring heat preservation time, simple processing, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

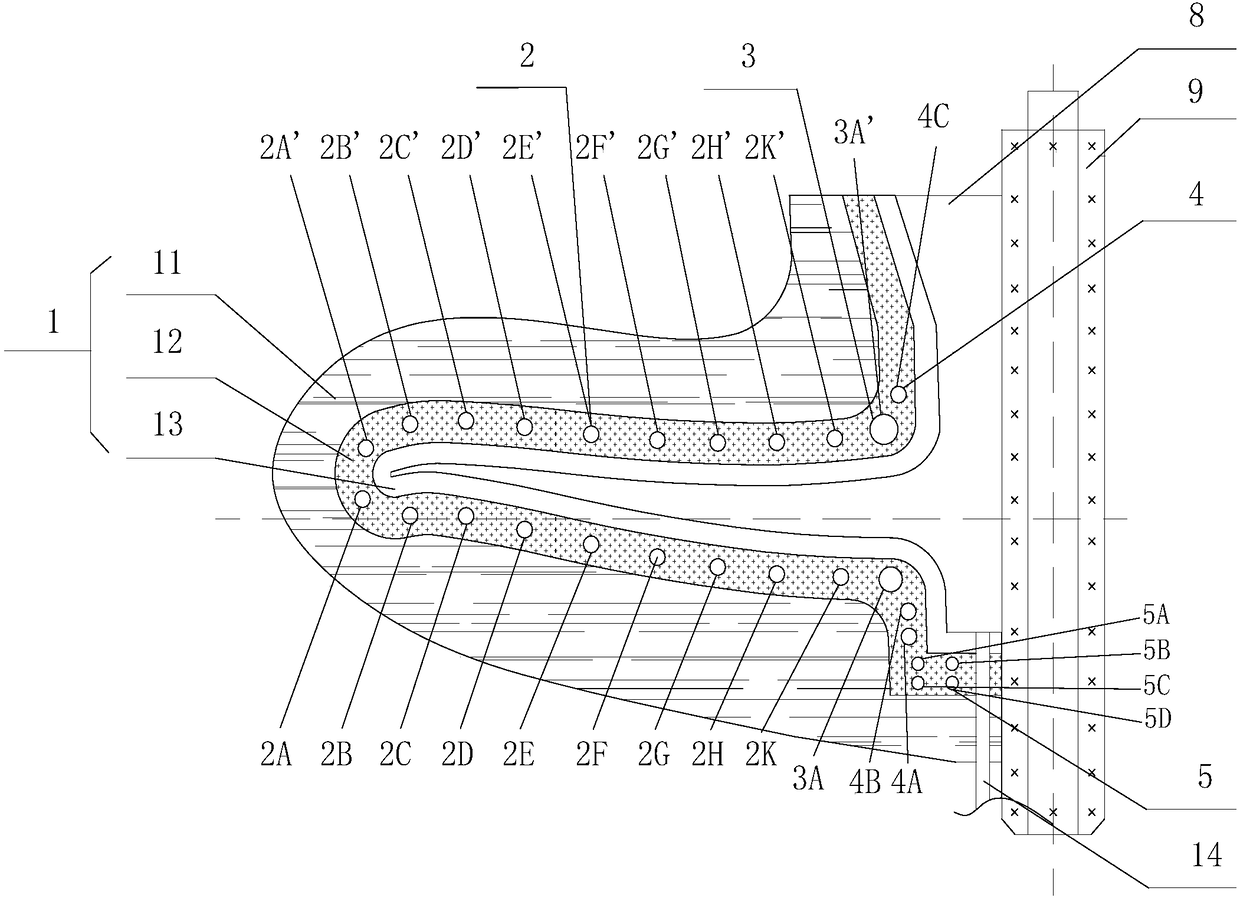

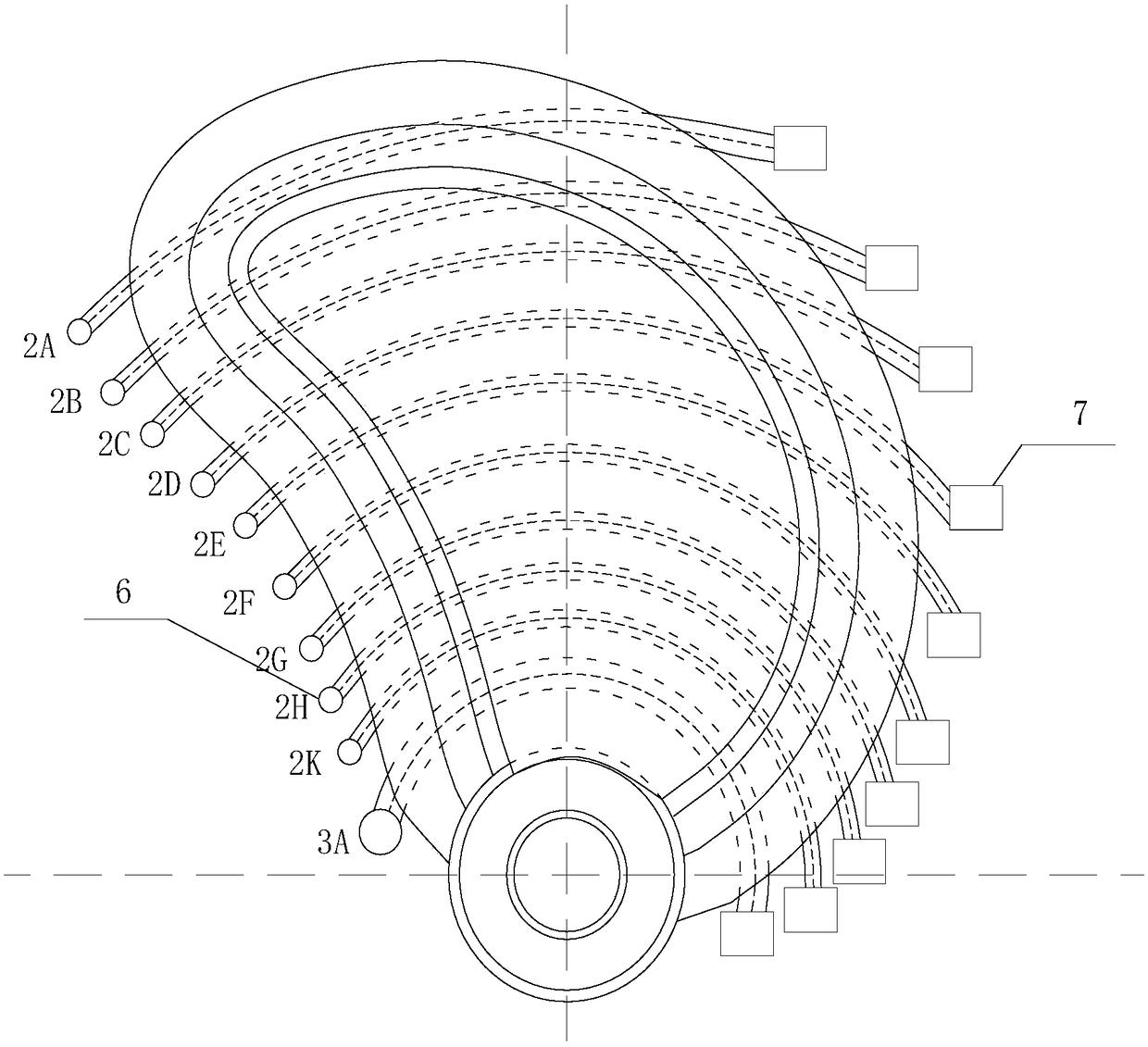

[0039] The specific embodiment of the present invention is shown in the accompanying drawings, and the control device includes: a sand mold 1, a blade control system 2, a blade root control system 3, and a blade hub control system; the blade control system 2, blade root control system System 3. The propeller hub control system is set sequentially from the propeller sand mold 1 blade to the propeller hub;

[0040] The sand mold 1 is sequentially provided with a back sand layer 11, an intermediate sand layer 12 and a surface sand layer 13 from the outside to the inside; a pouring system 14 is arranged at the paddle hub of the sand mold 1;

[0041] The blade part control system 2 includes: N cooling pipelines arranged at the middle sand layer 12 near the blade surface, and the numbers of the cooling and cooling pipelines are 2A, 2B, 2C, 2D...2H, 2K; the cooling pipelines installed at 12 places in the middle sand layer near the back of the blade, the cooling pipeline numbers are 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com