In-situ detection system and method for grinding wheel outline and grinding wheel outline error compensation method

A technology for in-situ detection and profile error, which is applied to grinding drives, components of grinding machine tools, metal processing equipment, etc. The effect of reducing contour machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

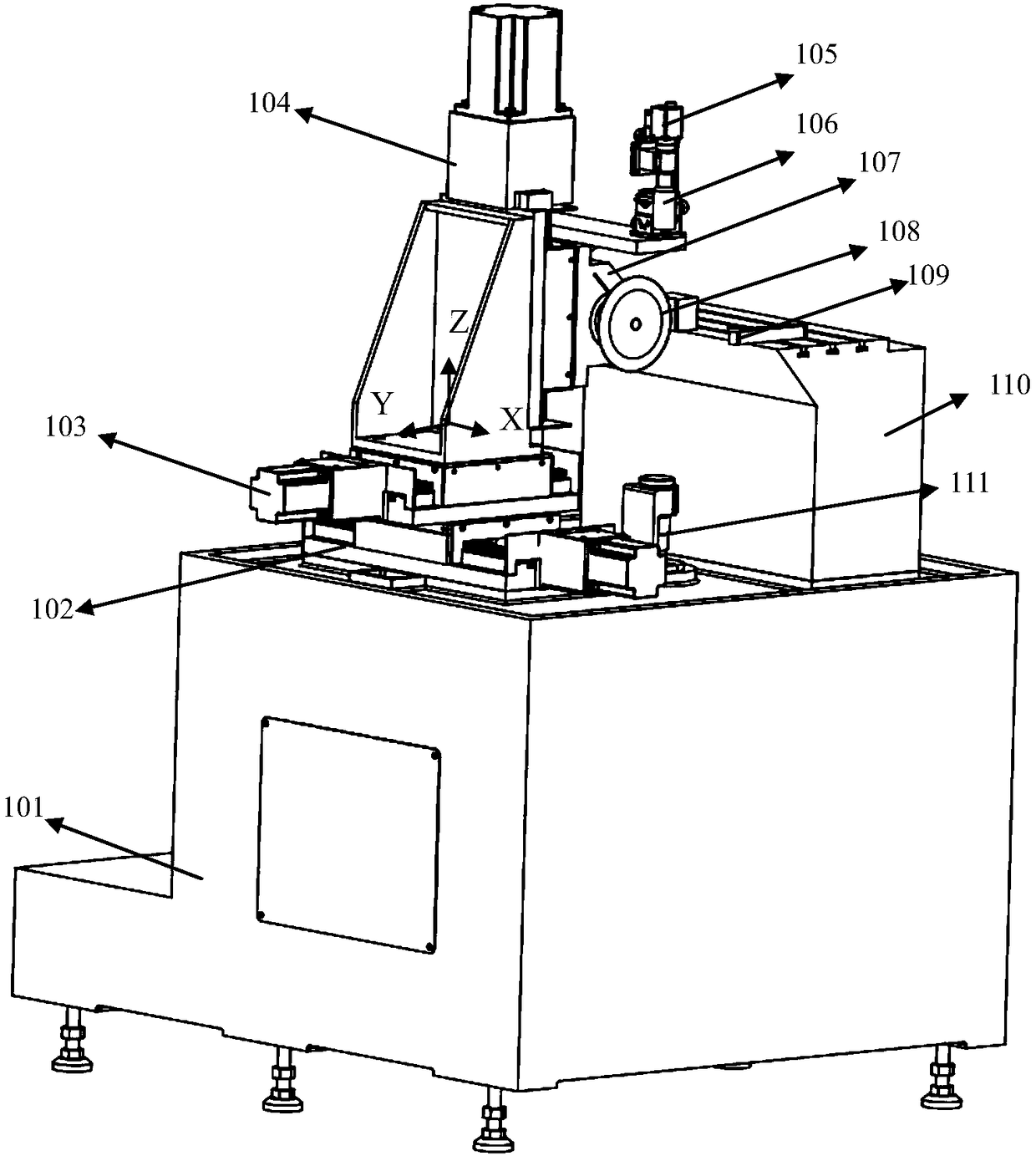

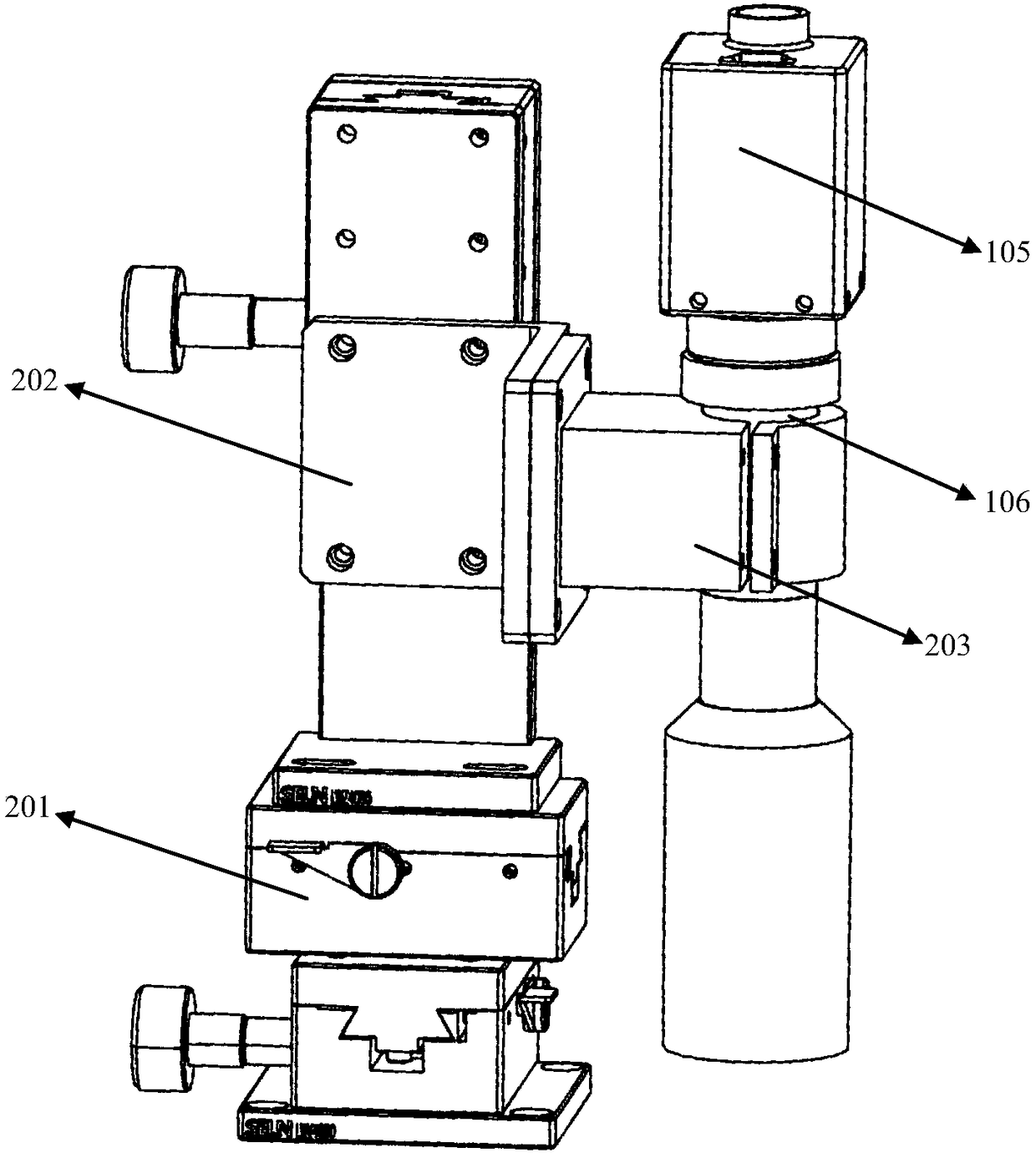

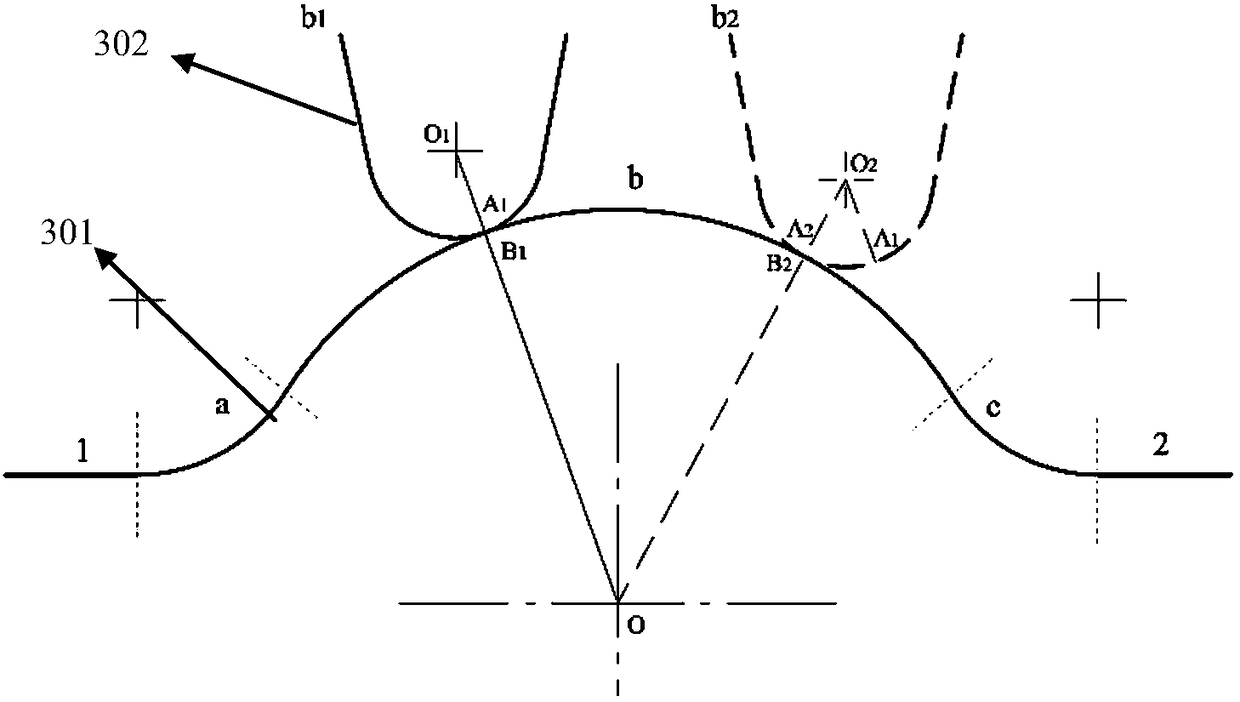

[0060] figure 1 A schematic diagram of the structure of the in-situ detection system for the sand profile provided by an embodiment of the present invention, such as figure 1 As shown, the system in this embodiment includes: a visual measurement assembly, a grinding wheel drive assembly, a grinding wheel dressing assembly 109, a workbench 110, and a bed 101; wherein, the visual measurement assembly includes: a CCD camera 105, a telecentric lens 106 and Parallel light source 111, the grinding wheel driv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap