Concrete mixer

A technology for concrete mixers and mixing shafts, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc. It can solve the problems of easy sticking to the mixing tank, affecting the mixing effect, and difficulty in fully mixing, etc., to achieve increased Large material convection, the effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

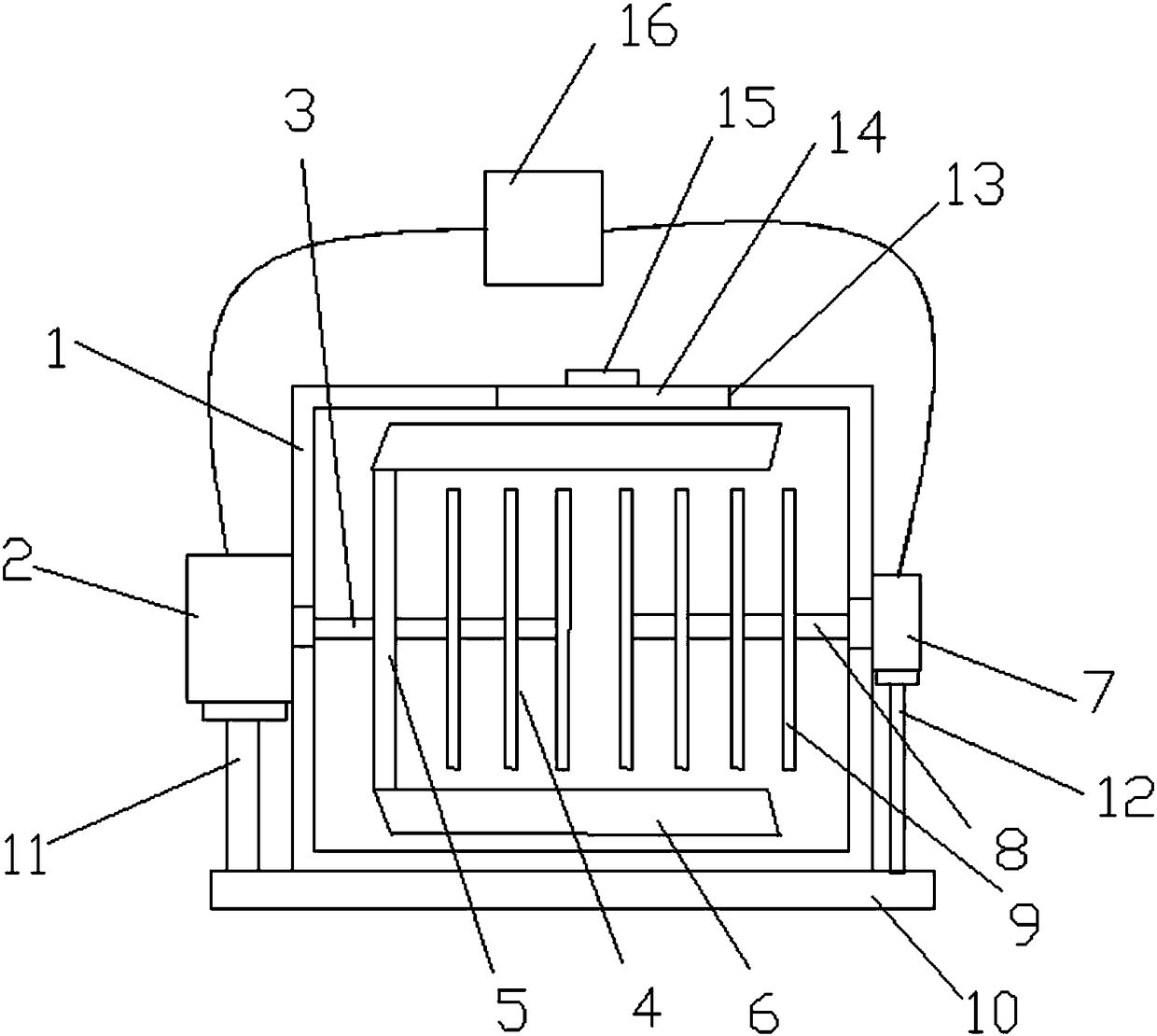

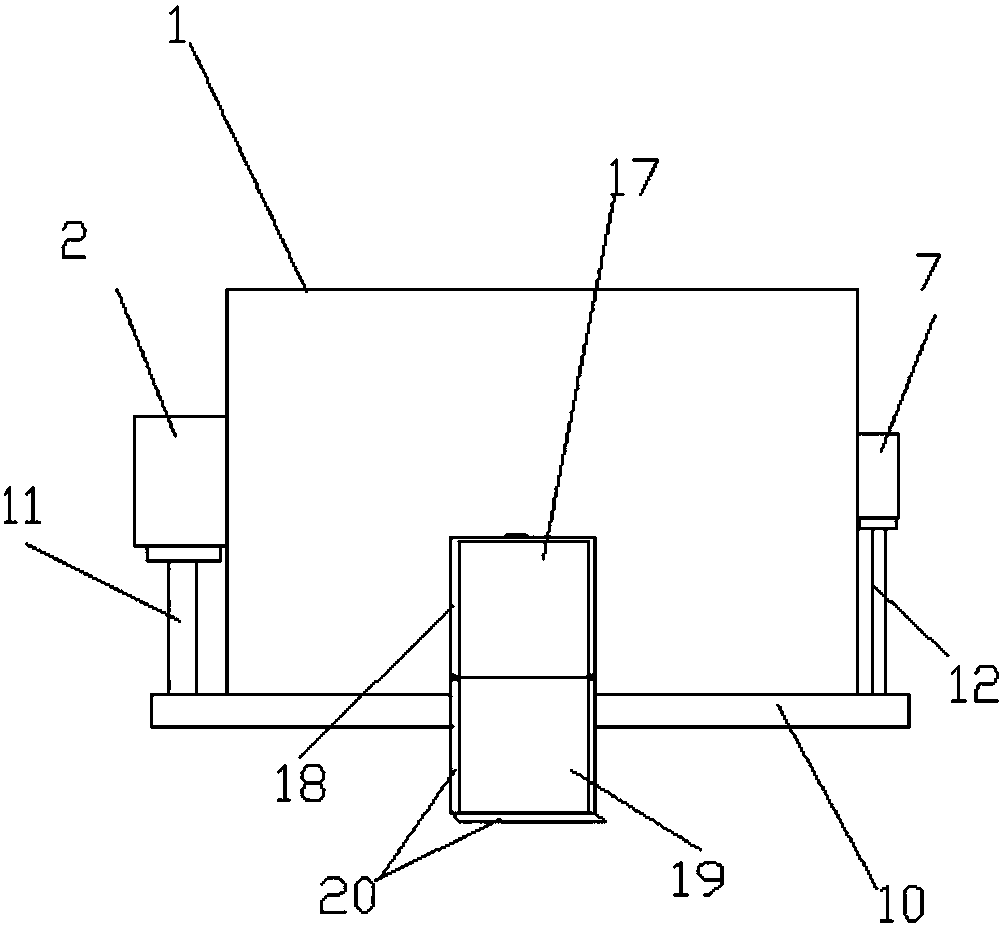

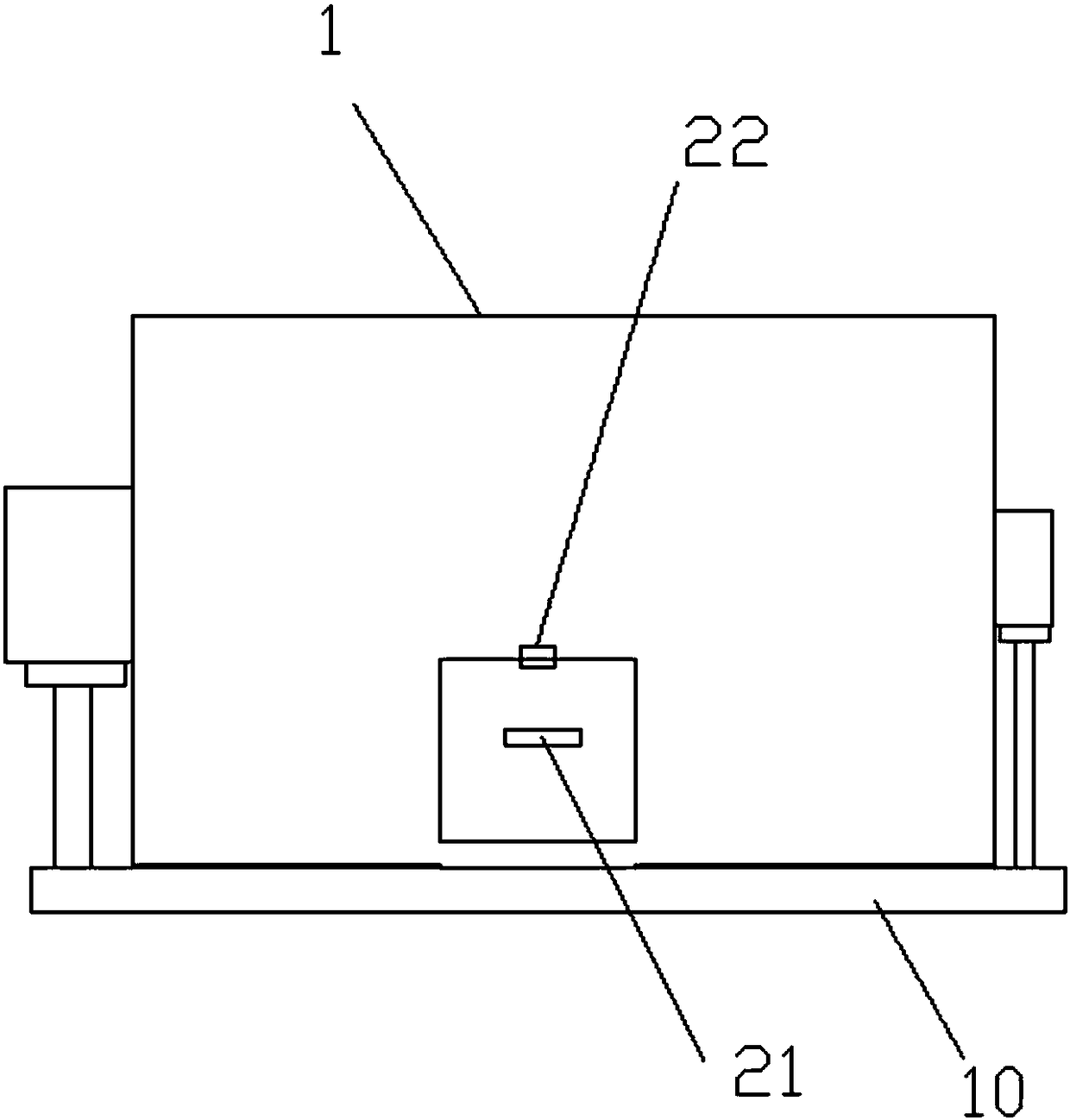

[0017] Such as Figure 1-3 As shown, a concrete mixer includes a mixing bucket 1 and a base 10, the mixing bucket 1 is arranged horizontally and fixedly mounted on the base 10, and the left side of the mixing bucket 1 is provided with a first motor 2. The output shaft of the first motor 2 is connected to one end of the first stirring shaft 3 through a bearing arranged on the left wall of the mixing tank 1, and the first stirring shaft 3 is located on the central axis of the mixing tank 1 , the other end of the first stirring shaft 3 extends to one-third to two-thirds of the length of the mixing tank 1, and the first stirring shaft 3 is equidistantly provided with a plurality of first stirring paddles 4. The first stirring paddle 4 is in the shape of a long plate, and it is fixed on the first stirring shaft 3, and the first stirring shaft 3 is the axis of symmetry, and the near left end of the first stirring shaft 3 is provided with The second stirring paddle 5 parallel to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com