One-pot liquefaction process of biomass

A technology for biomass and pretreatment of biomass, applied in the field of biomass one-pot liquefaction process, can solve the problems of small amount of biomass conveyed by pump, low biomass conversion rate, unstable transportation, etc., and achieve smooth operation. and conveying, reducing industrial costs and energy consumption, the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

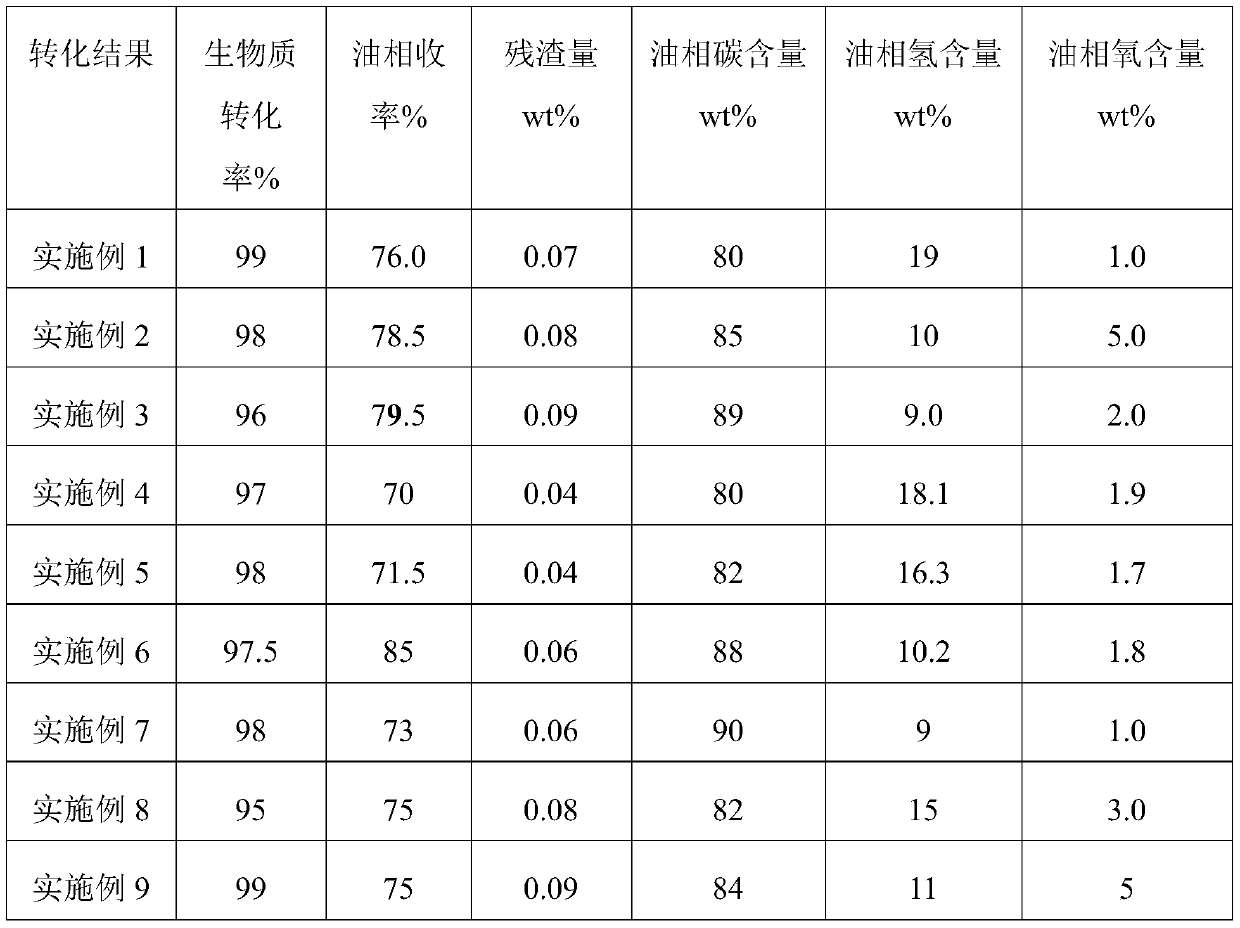

Examples

Embodiment 1

[0081] A one-pot liquefaction process of biomass, comprising the steps of:

[0082] Biomass Pretreatment

[0083] Put the wheat straw and corn straw into the drier and dry at 50°C for 5h until the water content is lower than 2wt%, and then send them into the superfine pulverizer for primary crushing, the median particle size after primary crushing is 100 μm, and then the primary crushing The crushed wheat straw and corn straw were sent to the plodder for compression extrusion molding at a temperature of 30°C and a pressure of 3 MPa, and then a secondary crushing treatment. The median particle size after the secondary crushing was 30 μm. The bulk density of wheat straw and corn straw after secondary crushing is 500kg / m 3 ,spare.

[0084] Catalyst preparation

[0085] S1. After the biochar is acidified, a biochar carrier is obtained;

[0086] S2. Vibrating and grinding the oxide of Mo and the above-mentioned biomass carbon carrier to obtain the biomass carbon loaded with ...

Embodiment 2

[0095] A one-pot liquefaction process of biomass, comprising the steps of:

[0096] Biomass Pretreatment

[0097] Put the rice straw and reed straw into the dryer and dry at 70°C for 3 hours until the water content is lower than 2wt%, and then send them into the superfine pulverizer for primary crushing, the median particle size after primary crushing is 300 μm, and then the primary crushing The crushed rice straw and reed straw were fed into the plodder for compression extrusion molding at a temperature of 60°C and a pressure of 0.5 MPa, and then secondary crushing was carried out. The median particle size after secondary crushing was 50 μm. The bulk density of rice straw and reed straw after secondary crushing is 400kg / m 3 ,spare.

[0098] Catalyst preparation

[0099] S1. After the biochar is acidified, a biochar carrier is obtained;

[0100] S2. After the oxides of W, the oxides of Fe and the above-mentioned biomass charcoal carrier are subjected to plane grinding a...

Embodiment 3

[0109] A one-pot liquefaction process of biomass, comprising the steps of:

[0110] Biomass Pretreatment

[0111] Send the cotton stalks into the drier and dry them at 60°C for 4 hours until the water content is lower than 2wt%, and then send them into the superfine pulverizer for primary crushing. The median particle size after primary crushing is 210 μm, and then the primary crushed Cotton stalks are fed into a briquetting machine for compression extrusion molding at a temperature of 55°C and a pressure of 2.1 MPa, and then secondary crushing is carried out. The median particle size after secondary crushing is 40 μm, and the The bulk density of cotton straw is 440kg / m 3 ,spare.

[0112] Preparation of biochar loaded with Mo oxide and Pd oxide

[0113] S1. After the biochar is acidified, a biochar carrier is obtained;

[0114] S2. Vibrating and grinding Mo oxides, Pd oxides, and the above-mentioned biomass charcoal carrier to obtain biochar with a particle size of 120-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com