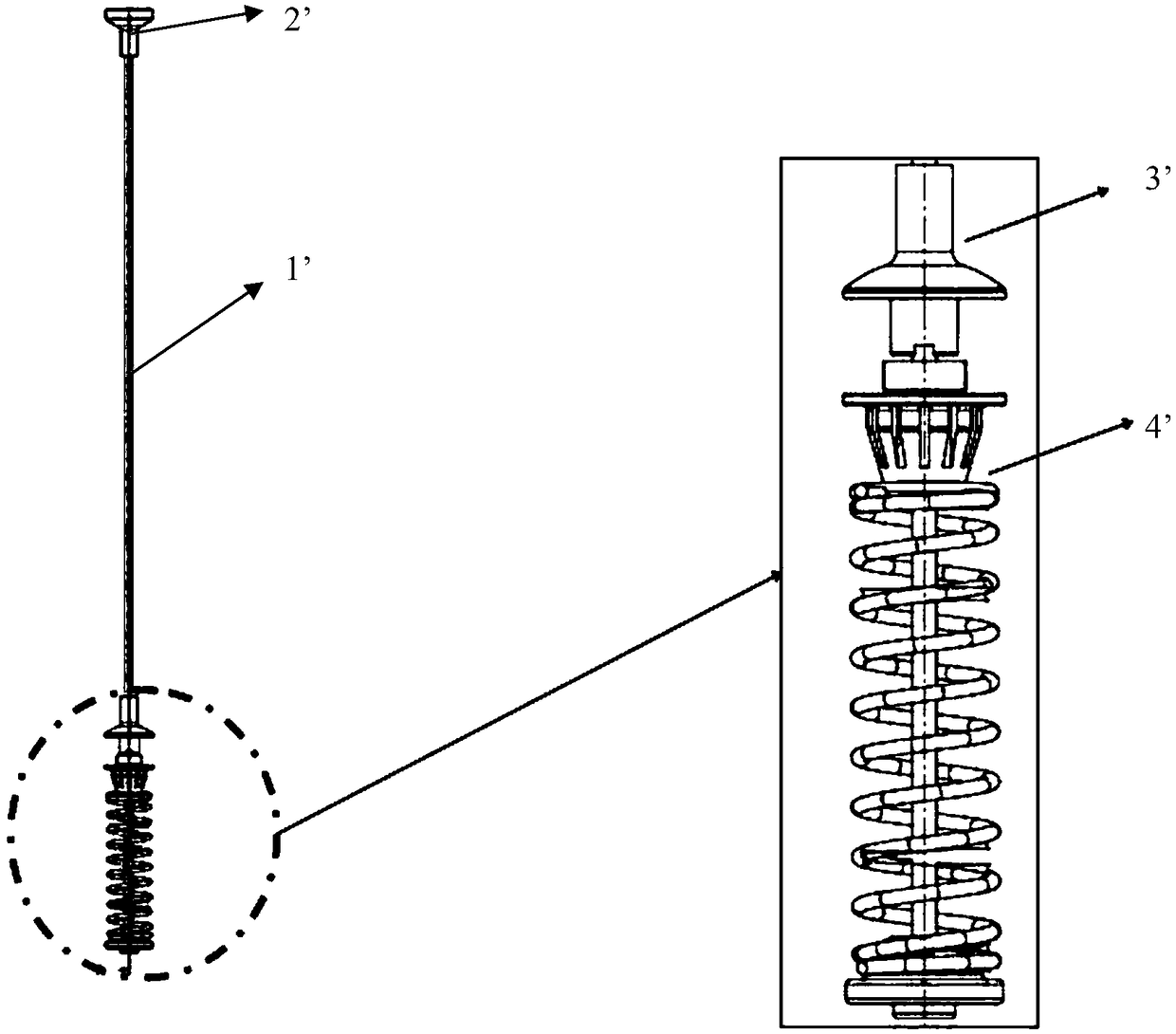

Buffering mechanism of washing machine suspender and washing machine suspender

A technology of a washing machine boom and buffer mechanism, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of affecting the shock absorption effect of the boom, rust damage of springs, and falling off friction plates, so as to achieve convenient installation in place, The effect of reducing the cost of use, avoiding damage and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

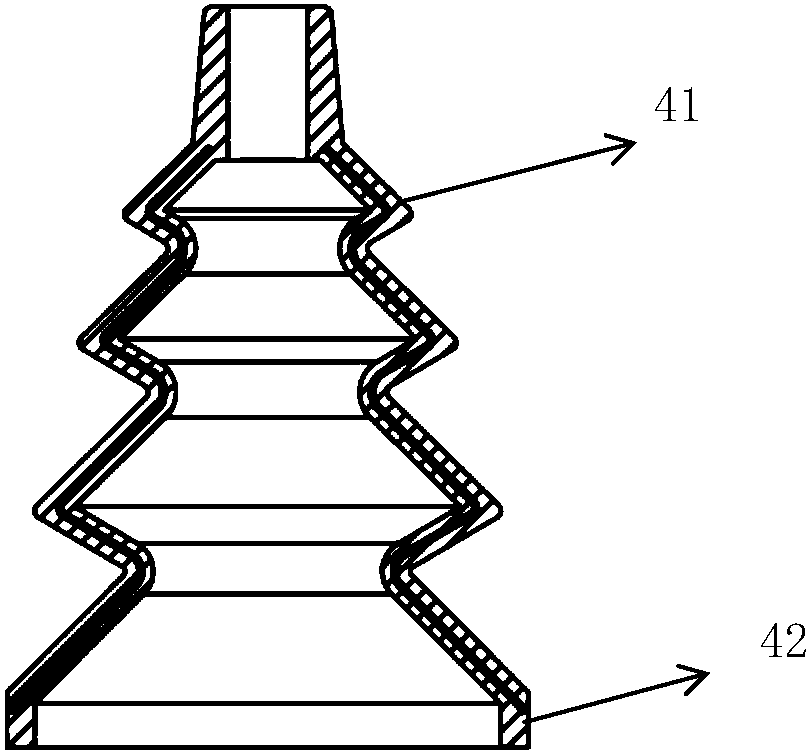

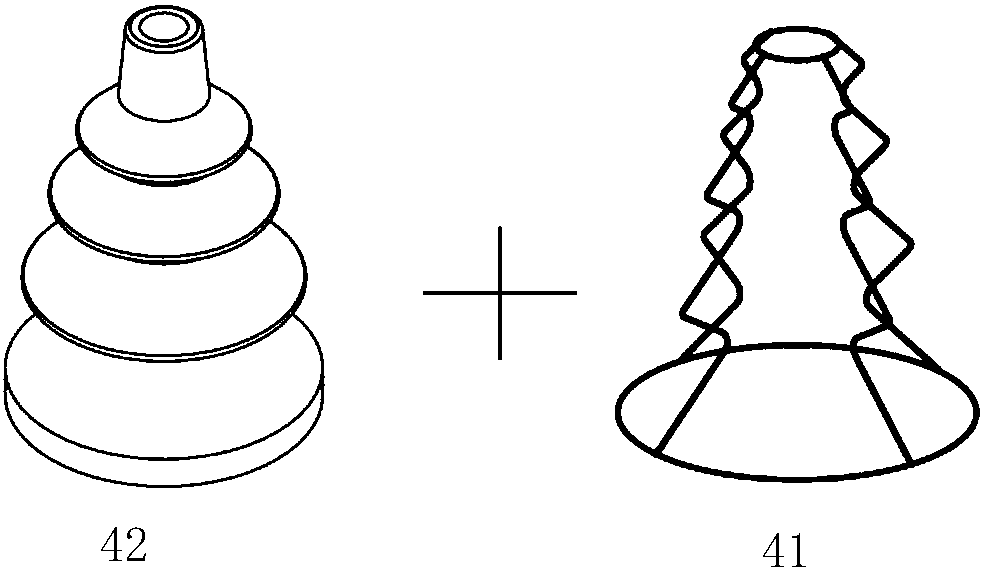

[0046] The rest is the same as that of Embodiment 1, except that the rigid support frame is an integral structure arranged around the suspender, and the flexible support layers are respectively formed on the inner and outer sides of the integral structure. Specifically, a whole piece of steel plate can be used to bend and form the rigid support frame, and the rubber material can be molded on the outside of the rigid support frame by in-mold injection molding. There are many structural forms of the rigid support frame, which are not limited here.

[0047] The invention discloses a buffer mechanism for a suspension rod of a washing machine. The buffer mechanism is formed by adopting an integrally formed rigid support frame and a flexible support layer, and the rigid support frame is completely covered in the flexible support layer to prevent the rigid support frame from being exposed to the outside. It is realized that while satisfying the shock absorption function of the suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com