Potassium-zirconium-carbonate cross-linking water-resistant agent and preparing method thereof

A technology of potassium zirconium carbonate and potassium carbonate, which is applied in the field of inorganic water-resistant agents, can solve the problems of inability to prepare high-performance potassium zirconium carbonate water-resistant agents, short storage time of potassium zirconium carbonate, and high cost, so as to achieve rapid curing of coatings and good The effect of comprehensive performance and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

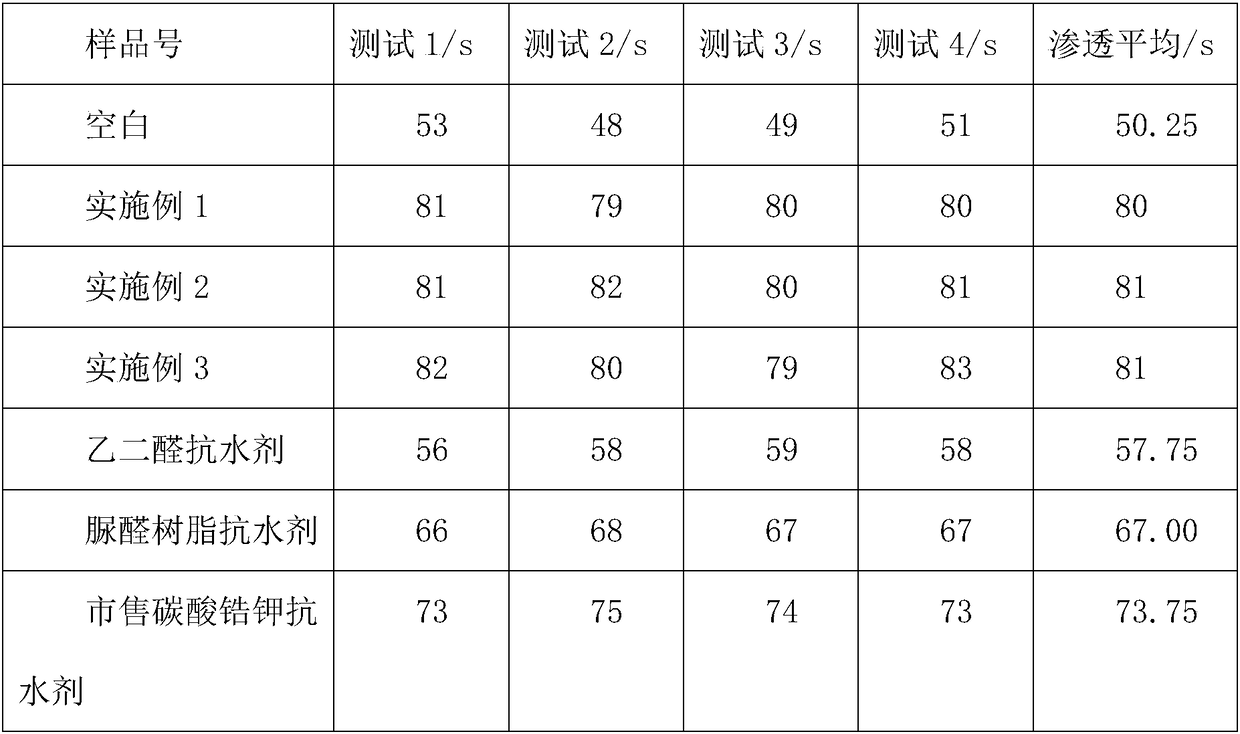

Examples

Embodiment 1

[0015] A zirconium potassium carbonate cross-linked water-resistant agent and a preparation method thereof, comprising the following steps:

[0016] (1) 140g anhydrous potassium carbonate is added 160ml water and is made into potassium carbonate solution, is made into 40% potassium carbonate solution;

[0017] (2) Put the solution into a 20°C water bath and heat it to raise the temperature of the solution to 20°C;

[0018] (3) Under stirring, 300g basic zirconium sulfate (Zr(Hf)O 2 : 41.3%) joins potassium carbonate solution;

[0019] (4) At 40°C, after reacting for 8 hours, filter, and the obtained filtrate is ammonium zirconium carbonate cross-linked water-repellent agent, whose Zr(Hf)O 2 The mass percentage is 20.6%, the pH: 11.6, and the solid content is 49.1%.

Embodiment 2

[0021] A zirconium potassium carbonate cross-linked water-resistant agent and a preparation method thereof, comprising the following steps:

[0022] (1) Add 180g of anhydrous potassium carbonate (1mol) to 120ml of water to make potassium carbonate solution;

[0023] (2) Put the solution into a 40°C water bath and heat it to raise the temperature of the solution to 40°C;

[0024] (3) Under stirring, 150g basic zirconium sulfate (Zr(Hf)O 2 :41%) joins potassium carbonate solution;

[0025] (4) After reacting for 6 hours, filter, and the filtrate obtained is zirconium carbonate ammonium cross-linked water-repellent agent, and its Zr(Hf)O 2 , the mass percentage is 20.5%, pH: 11.7, and the solid content is 50.6%.

Embodiment 3

[0027] A zirconium potassium carbonate cross-linked water-resistant agent and a preparation method thereof, comprising the following steps:

[0028] (1) Add 240g of anhydrous potassium carbonate to 60ml water to make potassium carbonate solution;

[0029] (2) Heating in a 70°C water bath to raise the temperature of the solution to 70°C;

[0030] (3) Put the solution under stirring action, 300g basic zirconium sulfate (Zr(Hf)O 2 : 40.8%) joins potassium carbonate solution;

[0031] (4) After reacting for 0.5 hours at 70°C, filter, and the obtained filtrate is the ammonium zirconium carbonate cross-linked water-repellent agent, whose Zr(Hf)O 2 , the mass percentage is 20.3%, pH: 11.6, and the solid content is 63.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com