Clapboard-type integration floor drain

A partition type, floor drain technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of inconvenient installation and maintenance, easy blockage of water traps, and odor from floor drains, so as to achieve convenient installation and maintenance, and deodorization. Long-lasting effect and high-frequency replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

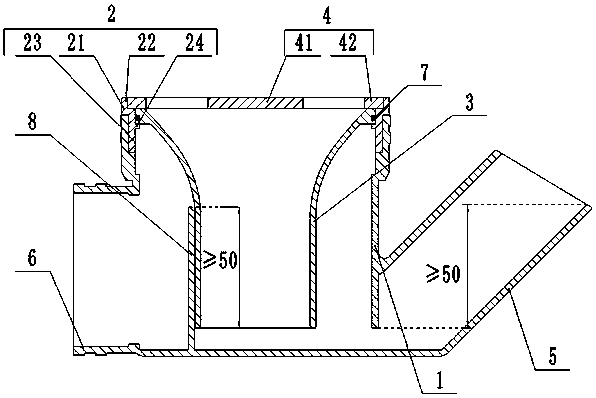

[0017] like figure 1 As shown, the clapboard-type integrated floor drain of the present invention includes a housing 1, a cover plate 2, a trumpet-shaped water seal pipe 3, a water grate 4, a 45° water inlet pipe 5, a water outlet pipe 6 and a partition 8. The shell The body 1 is a cylindrical shell with an open upper end, and the inner side of the upper part of the shell 1 has a stepped structure. The 45° water inlet pipe 5 and the water outlet pipe 6 are arranged around the outside of the shell 1, and the 45° water inlet pipe 5 The lower end communicates with the lower inner cavity of the housing 1, the upper end of the 45° water inlet pipe 5 communicates with the horizontal water inlet branch pipe through a 45° elbow, the water outlet pipe 6 is arranged horizontally, and one end of the water outlet pipe 6 is connected to the shell The lower inner cavity of the body 1 is communicated, the other end of the outlet pipe 6 is communicated with the horizontal drain pipe, a partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com