Efficient heat exchanger

A heat exchanger, high-efficiency technology, applied in the direction of indirect heat exchangers, heat exchanger shells, heat exchange equipment, etc., can solve the problems of short contact time, low heat exchange efficiency, small temperature difference, etc., to increase heat exchange methods, Improve heat transfer efficiency, the effect of high-efficiency heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

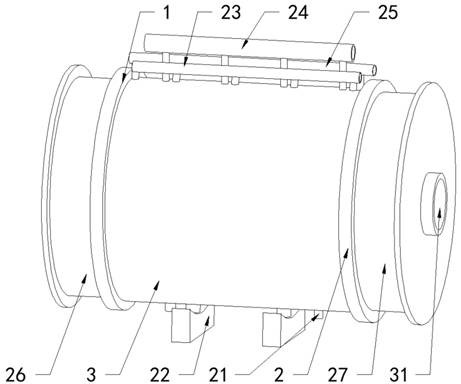

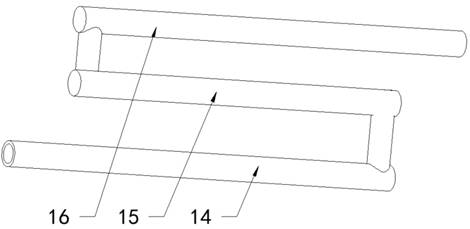

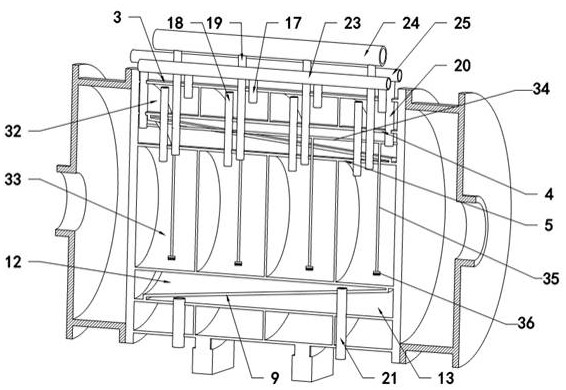

[0027]ReferFigure 1-5 A highly efficient heat exchanger, including the feed baffle 1 and the discharge baffle 2, respectively, on both faces of the intake barrel 26 and the discharge barrel 27, the feed barrel 26, and the discharge barrel 27, respectively. The inner layer fixing tub 5, sandwich fixing bucket 4 and outer fixing bucket 3, laminated bucket 4 and outer layer fixing bucket 3, the inner layer fixing bucket 5 is sequentially fixed. The inner heat exchange chamber 8, the inner fixed tub 5 is formed between the sandwich fixing tub 4, and the outer layer heat exchange chamber 6 is formed between the sandwich fixing tub 4 and the outer layer fixing tub 3, the outer heat exchange chamber 6 The first heat exchange chamber 32 that is not connected to each other is provided along the axial center line, and there is a plurality of seconds along the inner heat exchange chamber 8 in the axial center line 32 corresponding to the plurality of first heat exchange chambers 32. The heat e...

Embodiment 2

[0036]In the process of carrying out the invention, after the A solution filled with the first heat exchange chamber 32, the second vent tube 18 flows into the second heat exchange chamber 33, and after the second heat exchange chamber 33 is filled, Finally, the heat exchanger is discharged from the third vent tube 19, and the a solution having a lower temperature first enters the bottom of the second heat exchange chamber 33, exchanged heat with the B solution bottom at the bottom of the second heat exchange chamber, and then A solution absorbs heat. The temperature rises, exchange heat from the B solution above the second heat exchange chamber 33 during the rise in the rising. In this process, when the temperature is different from the temperature, the thermal A solution is mixed in the second heat exchange chamber 33, since the solution itself, the temperature high a solution increases to the upper, low temperature portion a solution At the bottom, the amount of heat exchanged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com