A steel structure large bolt gusset plate installation opening and closing device and installation method

A technology for opening and closing devices and bolt joints, which is applied in building construction, building material processing, construction, etc., can solve the problems of time-consuming, affecting the installation period, and large auxiliary measures, so as to improve the convenience of installation, improve safety and reliability. performance, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

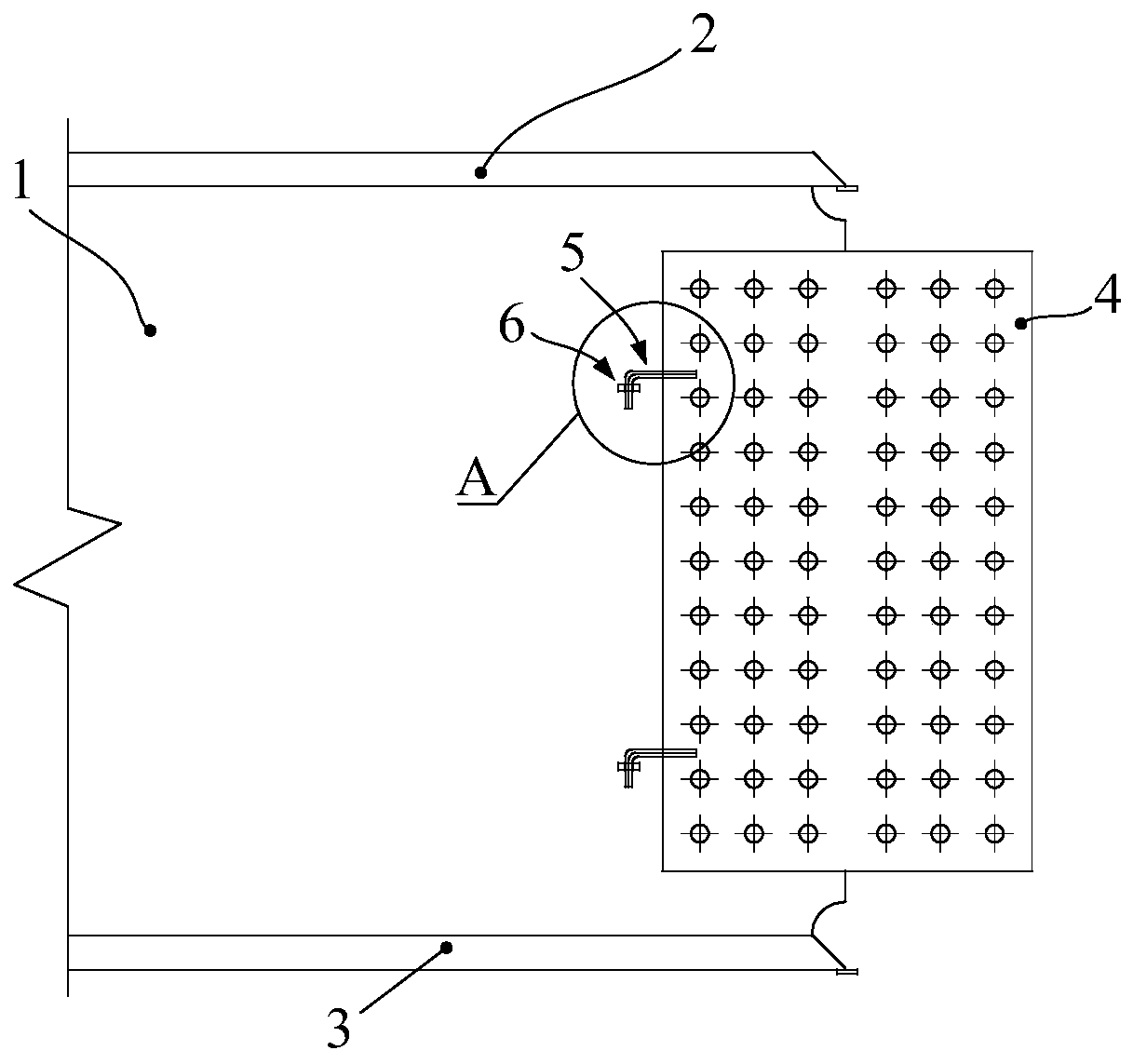

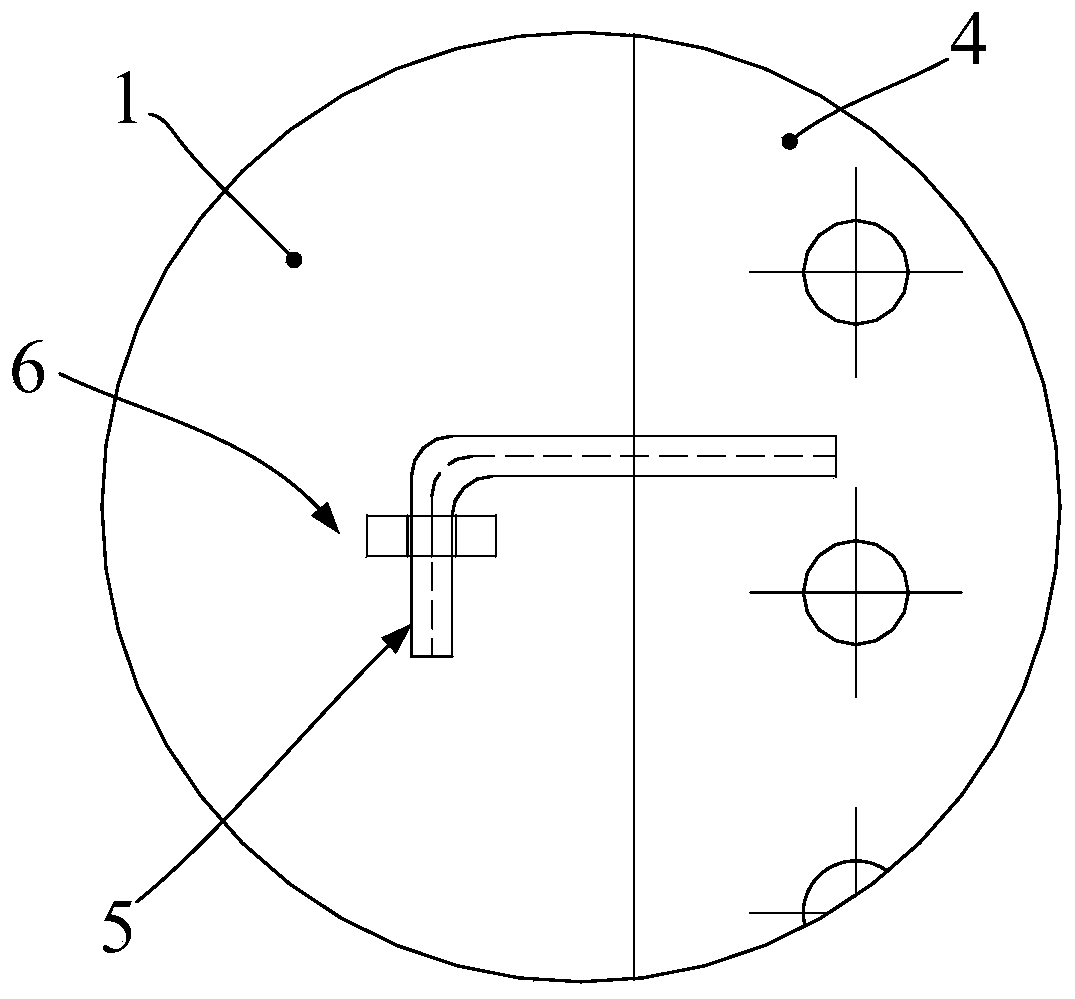

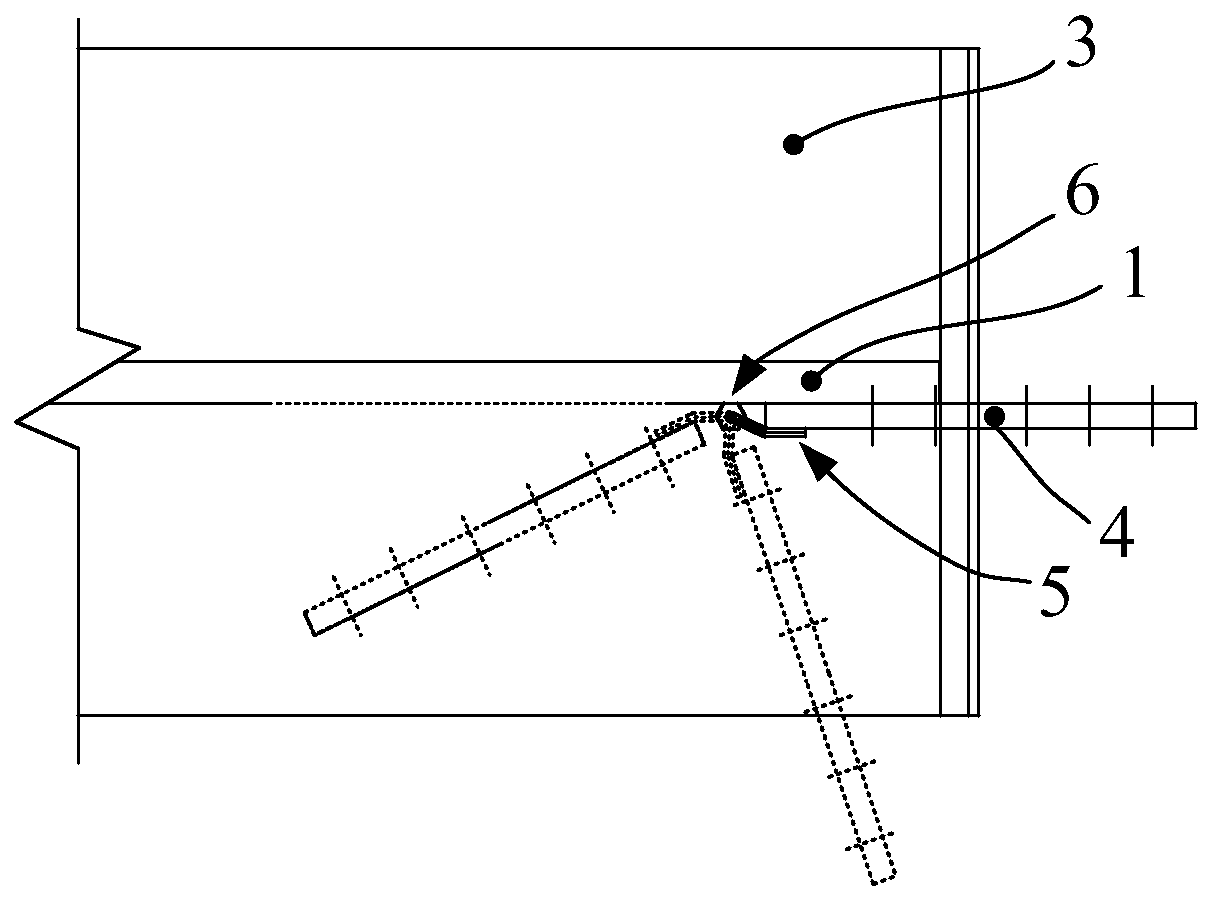

[0035] See Figure 1 to Figure 3 , the steel structure large-scale bolt gusset plate installation opening and closing device in the embodiment of the present invention includes a steel beam and a gusset plate 4, the gusset plate 4 and the steel beam web 1 are pivotally connected by an opening and closing device, and the opening and closing device includes a plurality of fixed The flipping shaft 5 matching the sleeve 6 and the fixed sleeve 6, the side of the fixed sleeve 6 is fixedly connected with the surface of the steel beam web 1, the flipping shaft 5 is L-shaped, and a section of the flipping shaft 5 is inserted into the center hole of the fixed sleeve 6, The end of the other section of the turning shaft 5 is welded and fixedly connected with the gusset plate 4 .

[0036] In this embodiment, a plurality of fixed sleeves 6 are distributed up and down along the side of the steel beam web 1 , and the central holes of the fixed sleeves 6 are on the same vertical line.

[0037...

Embodiment 2

[0041] The large bolt gusset plate installation opening and closing device of the embodiment of the present invention includes a plurality of first fixed sleeve seats 8 respectively connected to the surface of the web 1 of the steel beam, and a plurality of second fixed sleeves fixedly connected to the surface of the gusset plate 4 Seat 11 and the overturning connecting rod 7 that is connected with the first fixed sleeve seat 8 and the second fixed sleeve seat 11 respectively, the overturning connecting rod 7 includes two shaft sections that are perpendicular to each other, and the ends of the two sections of shaft sections are provided with outer The end of the shaft section inserted into the first fixed sleeve seat 8 is threaded and connected to the limit nut 9, while the other section of the shaft end passing through the second fixed sleeve seat 11 is threaded and connected with two parallel nuts 10, two parallel nuts 10 respectively and tight to the two ends of the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com