Heat dissipating system and vehicle lamp

A heat dissipation system and heat dissipation device technology, applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of poor heat dissipation effect of the heat dissipation system, and achieve the effects of improving heat dissipation effect, enhancing air flow, and accelerating air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

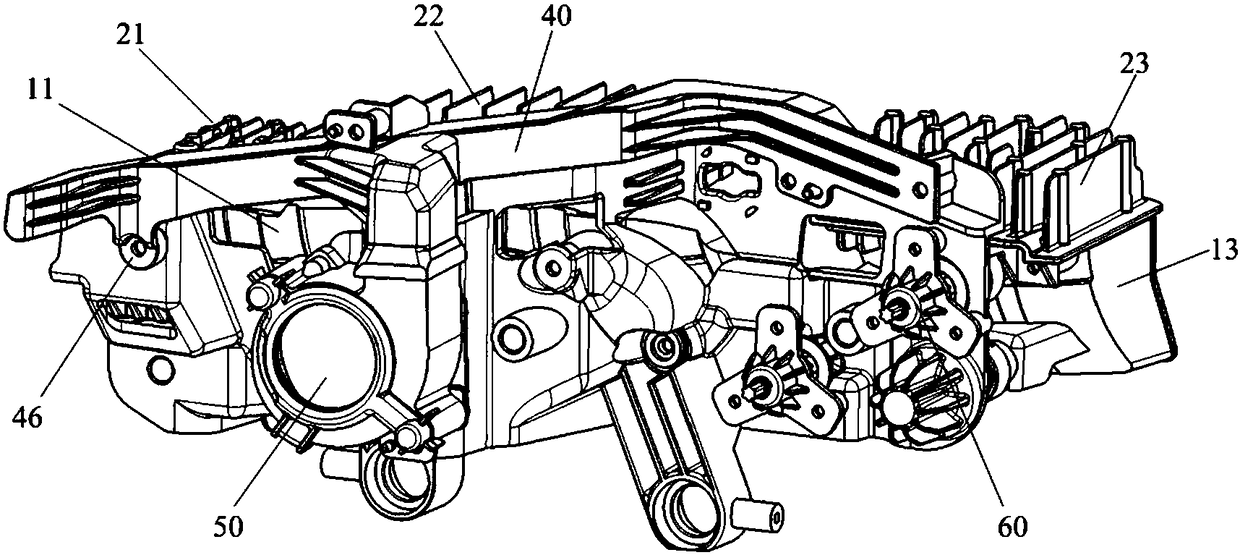

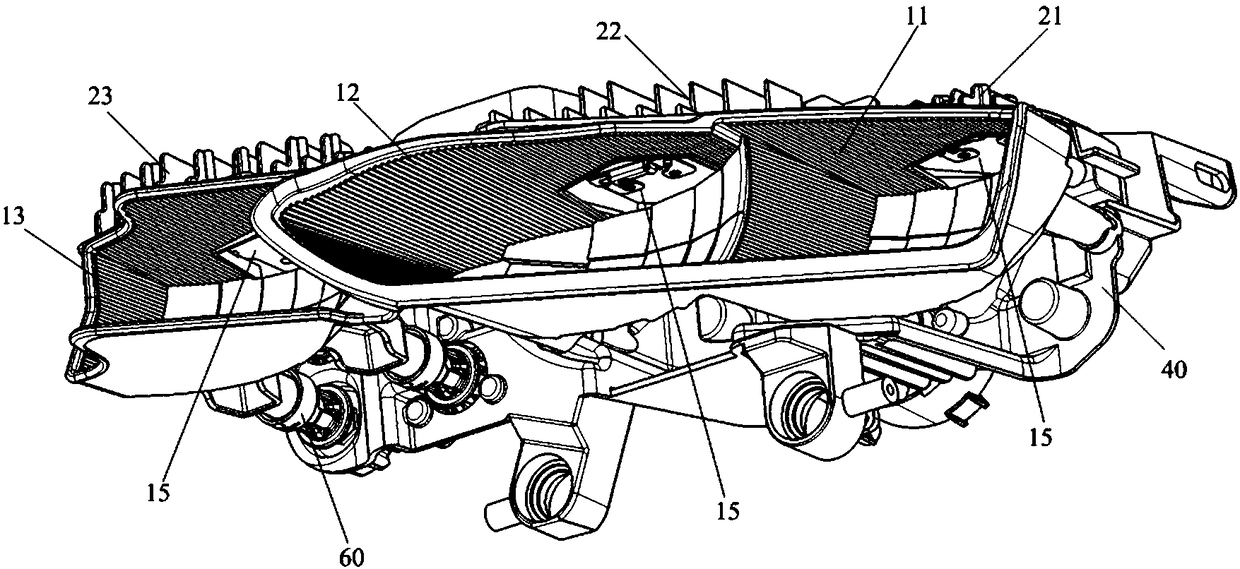

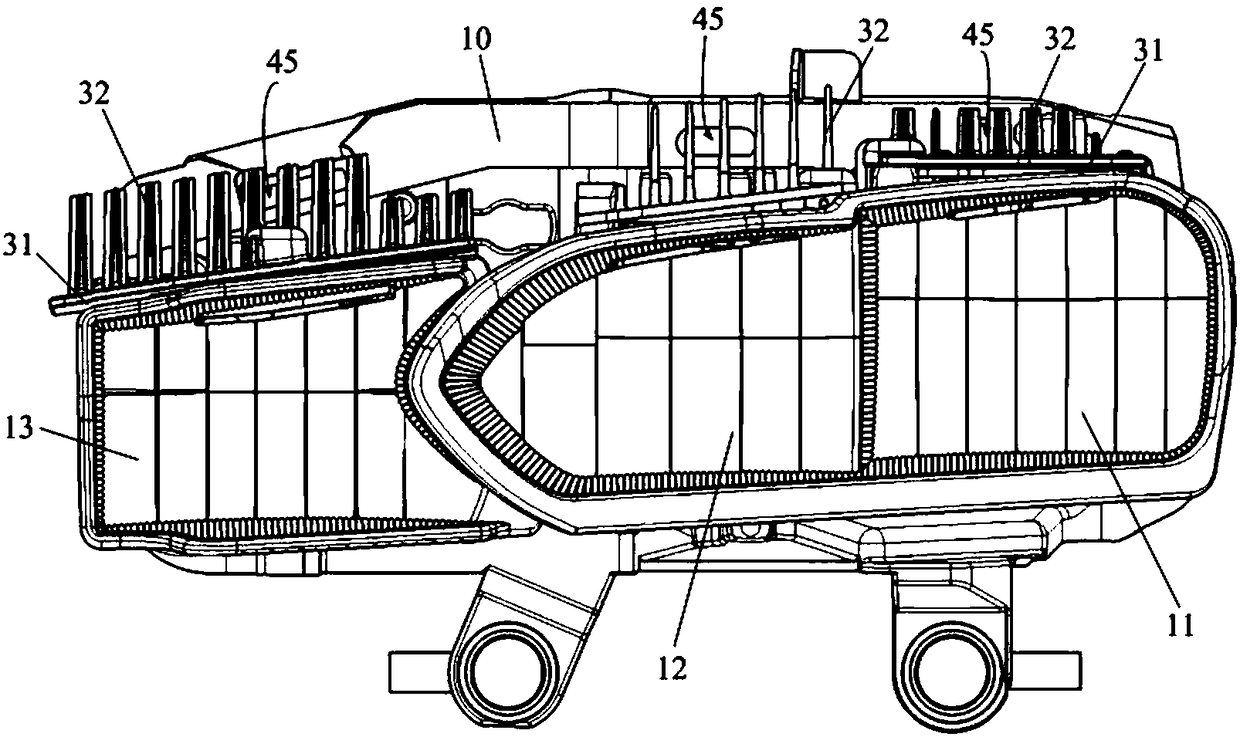

[0046] Such as Figure 1-5 As shown, the heat dissipation system provided by the embodiment of the present invention includes: an air guiding pipeline 40, an air supply device 50, and a main low beam heat dissipation device 21 respectively installed on the main low beam reflector 11, and a main low beam heat dissipation device 21 installed on the auxiliary low beam reflector The auxiliary low beam cooling device 22 on the 12 and the high beam cooling device 23 installed on the high beam reflector 13. Wherein, the air outlet of the air supply device 50 communicates with the air inlet 44 of the air guiding pipeline 40, and the air outlet 45 of the air guiding pipeline 40 faces the main low beam cooling device 21, the auxiliary low beam cooling device 22 and the high beam cooling device respectively. twenty three.

[0047] During the use of the heat dissipation system provided by the embodiment of the present invention, the main low beam heat dissipation device 21 dissipates heat ...

Embodiment 2

[0064] Embodiment 2 of the present invention provides a vehicle lamp, including: a main low beam reflector, an auxiliary low beam reflector, a high beam reflector, and the heat dissipation system provided in Embodiment 1 above. In the heat dissipation system, the main low beam heat dissipation device is installed on the main On the low beam reflector, the auxiliary low beam cooling device is installed on the auxiliary low beam reflector, and the high beam cooling device is installed on the high beam reflector.

[0065] During specific implementation, the air guide pipeline in the cooling system is connected to the main low beam reflector, auxiliary low beam reflector and high beam reflector, and the main low beam reflector, auxiliary low beam reflector and high beam reflector are all connected to each other. Mounting holes are provided, and LED chips are respectively arranged in the mounting holes, and the LED chips are connected with the corresponding main low beam cooling dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com