Pressure sensitive paper accuracy test method, device and system

A technology of precision testing and pressure-sensitive paper, applied in the field of testing, can solve problems such as low accuracy, achieve the effects of improving accuracy, avoiding precision testing errors, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

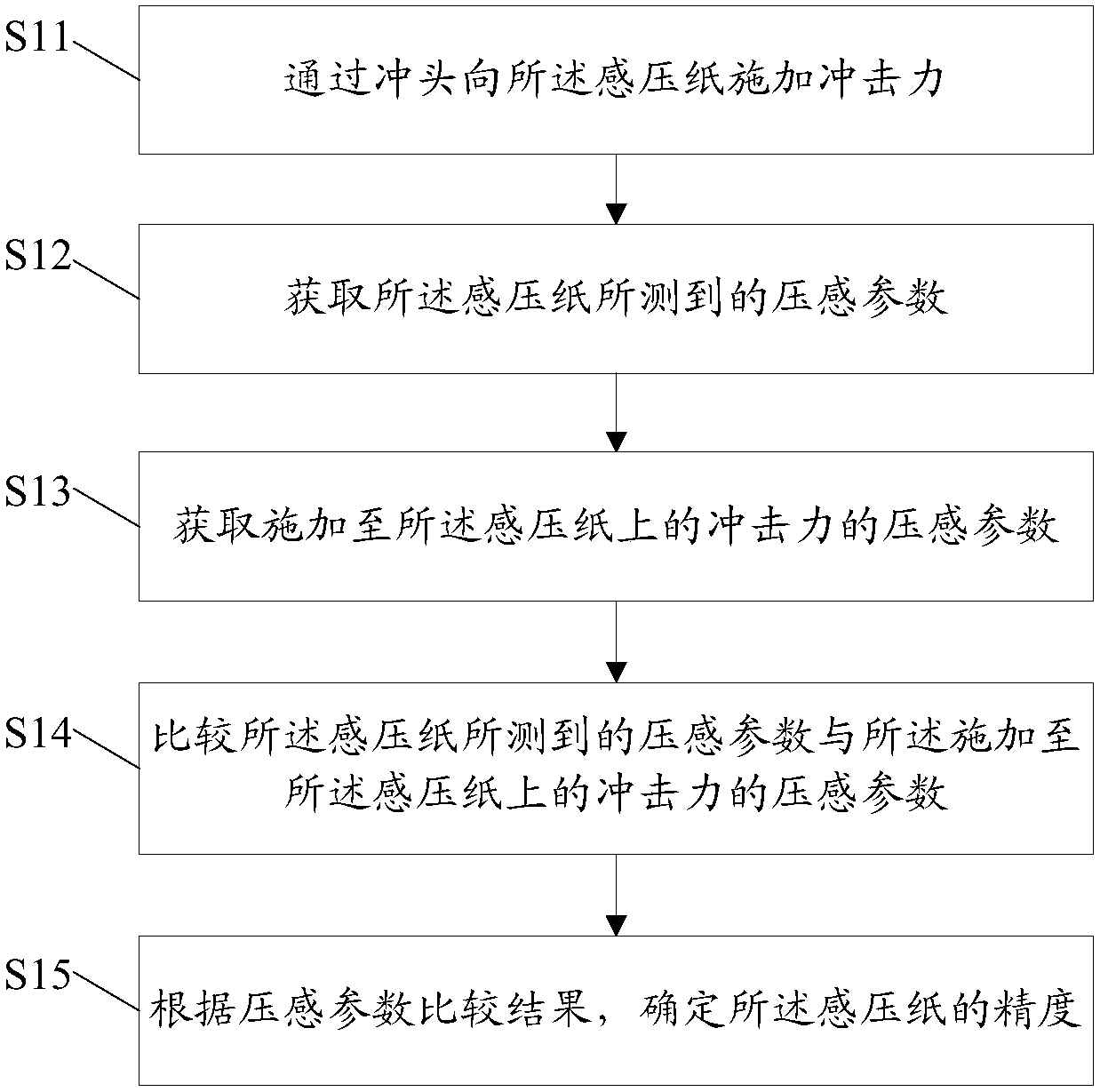

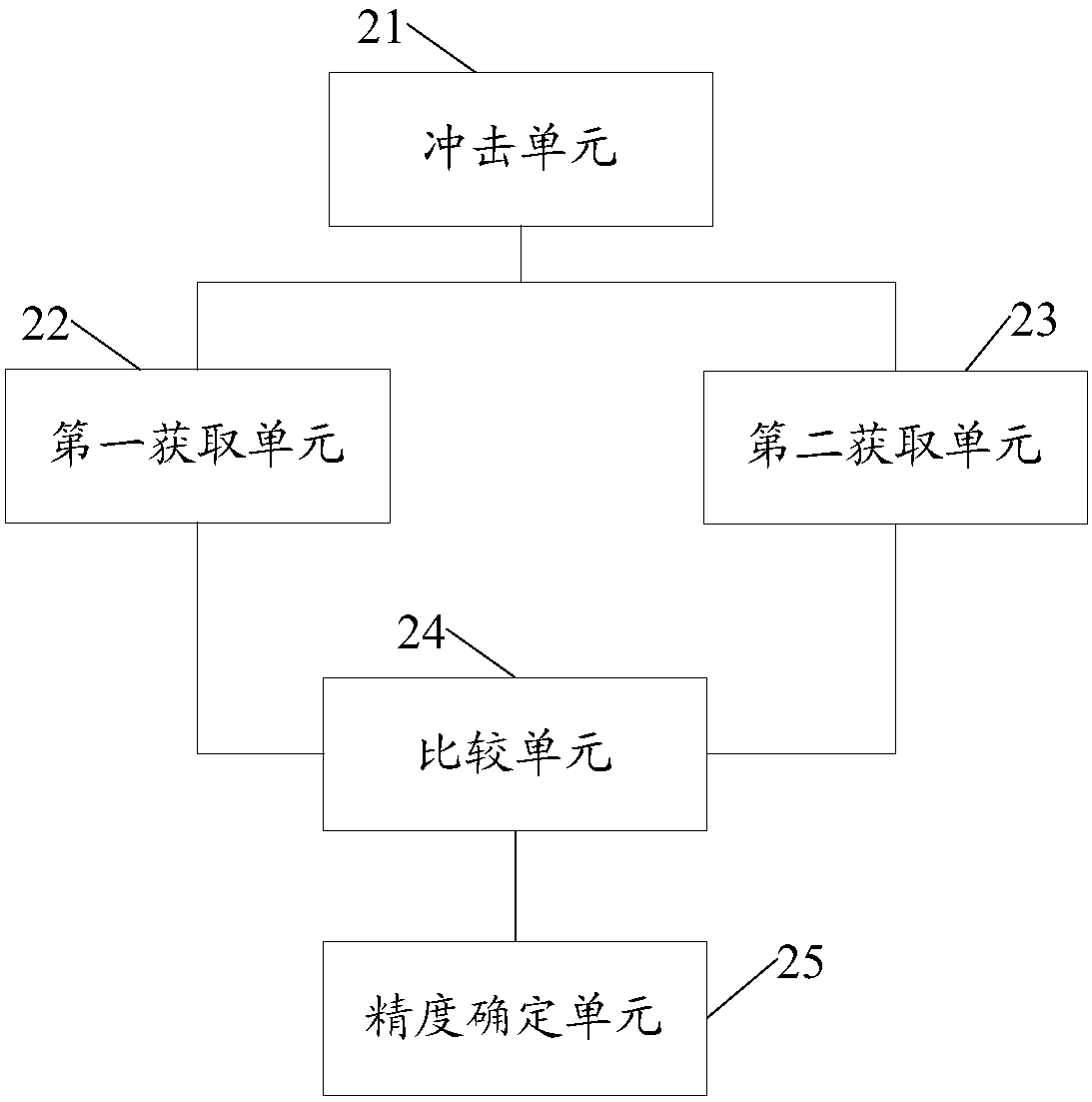

[0028] In order to improve the test accuracy of the pressure-sensitive paper, in the embodiment of the present invention, by applying an impact force to the pressure-sensitive paper, the pressure-sensitive parameters measured by the pressure-sensitive paper and the pressure of the impact force applied to the pressure-sensitive paper are obtained. Sensitive parameters, and then compare the pressure-sensitive parameters measured by the pressure-sensitive paper with the pressure-sensitive parameters of the impact force applied to the pressure-sensitive paper, and then determine the pressure-sensitive parameters according to the comparison results of the pressure-sensitive parameters The precision of the paper does not need to be simulated to calculate the pressure on the pressure-sensitive paper, so the error of the precision test of the pressure-sensitive paper can be reduced, and the accuracy of the precision test of the pressure-sensitive paper can be improved.

[0029] In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com