Method and device for testing electrochemical corrosion resistance of pole sealant

A technique for corrosion testing and corrosion strength, applied in measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., to achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

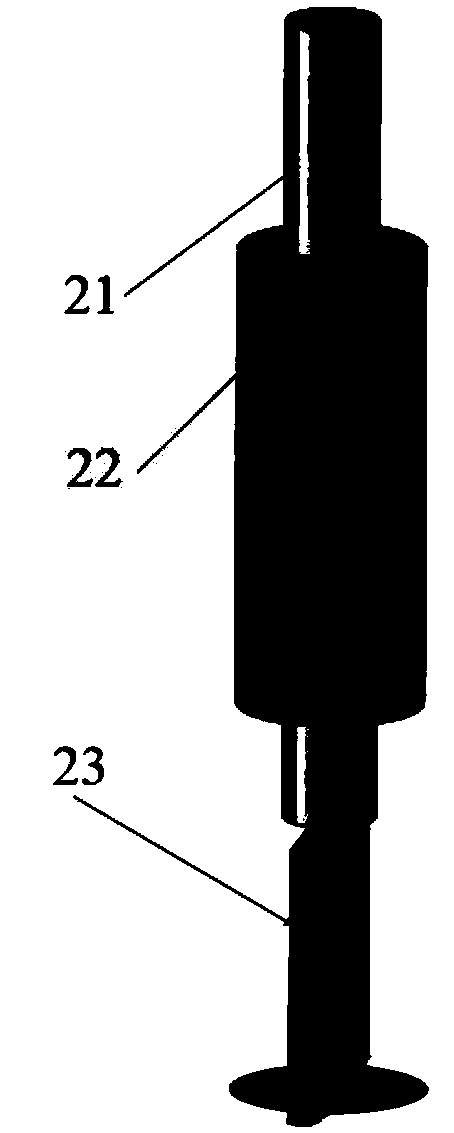

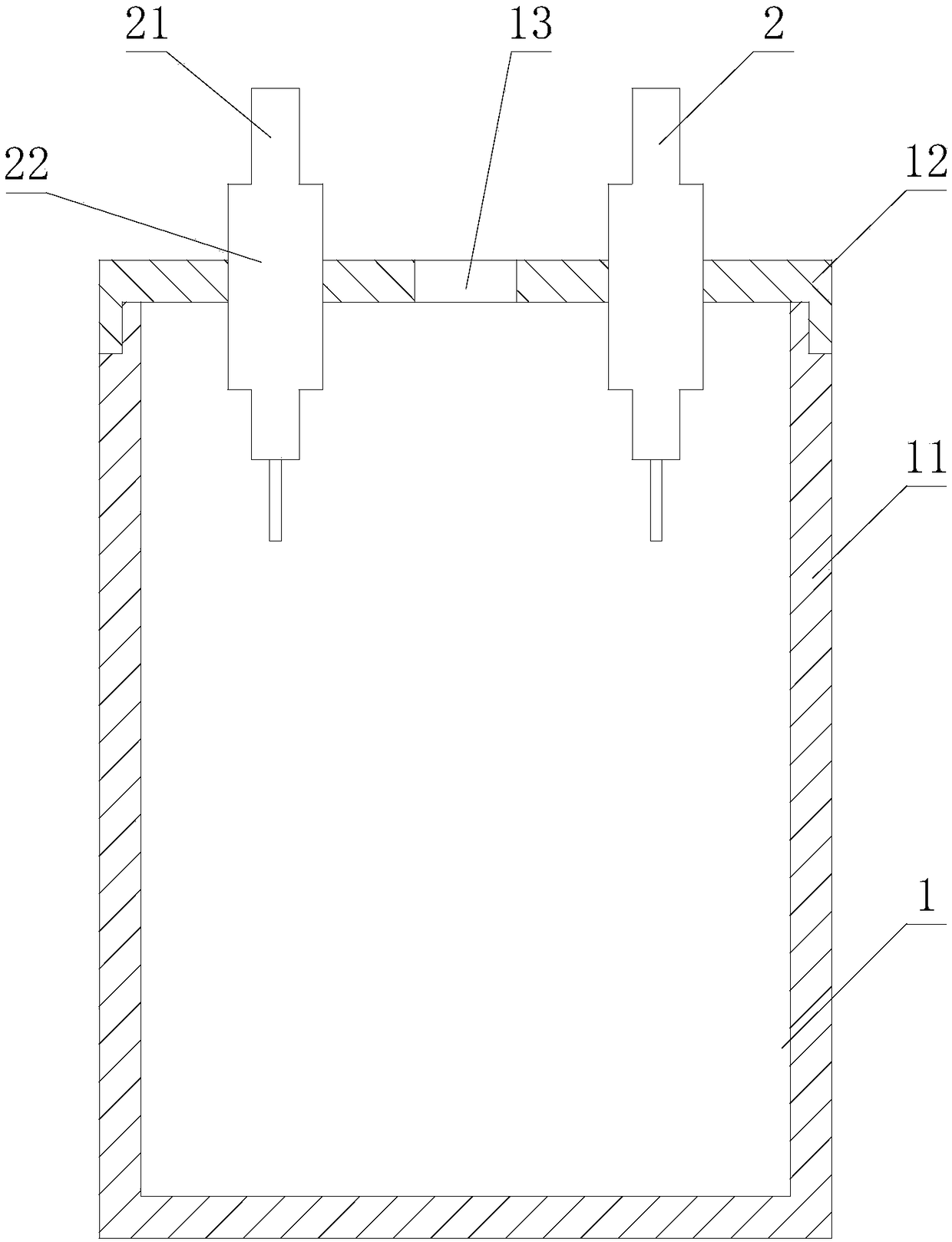

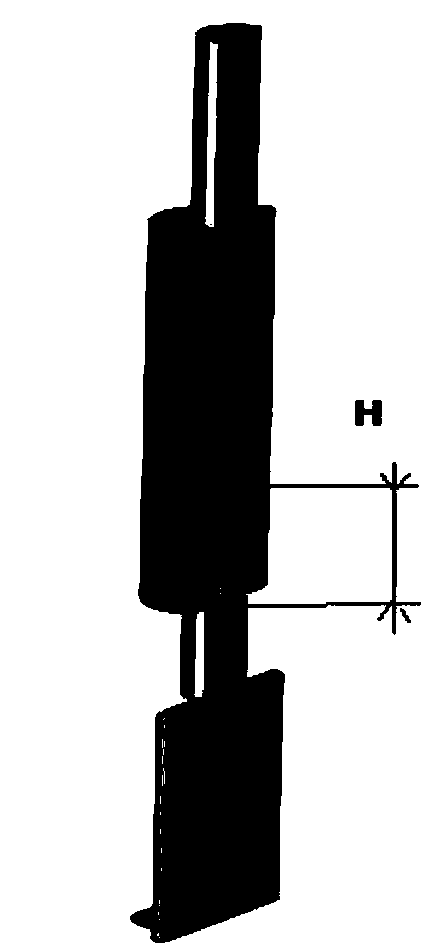

[0039] Pole sealant electrochemical corrosion resistance test device, such as figure 1 As shown, it includes a battery container 1 and positive and negative terminals 2. The battery container includes a housing 11 and a cover 12. The cover is provided with a pole hole. The schematic diagram of the lead terminal structure is shown in figure 1 and figure 2 As shown, the positive and negative terminals include a positive lead terminal 21 and a negative lead terminal, the middle of the positive lead terminal 21 is provided with a sealant column 22, and the bottom is connected with a lead plate 23, and the middle of the negative lead terminal is provided with Sealant post with lead plate attached at the bottom. The sealant column is fixed in the pole hole.

[0040] An O-ring is provided between the sealant column and the pole hole.

[0041] The cover of the battery tank is provided with a liquid injection hole 13 . The liquid injection hole is provided with a pressure relief v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com