Optimal Design Method of Impeller Blade Structure of Large Turboexpander Considering Defects

A turboexpander and impeller blade technology, which is applied in calculation, special data processing applications, instruments, etc., can solve the problems that the blade parameter optimization direction does not conform to the actual situation, the expected quality cannot be achieved, and the performance of the impeller is affected, so as to save materials , the error is small, the effect of reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

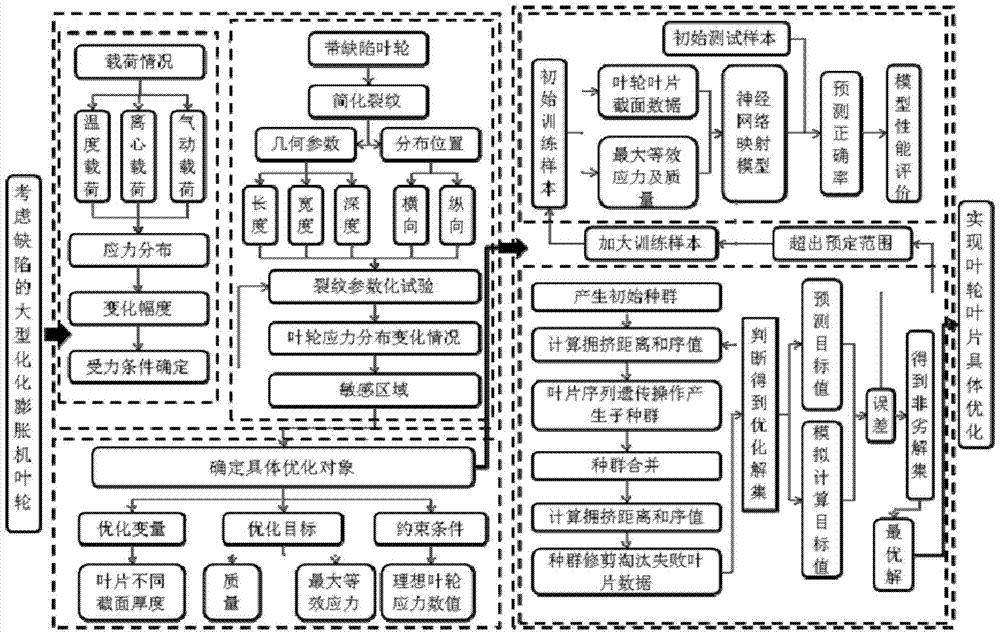

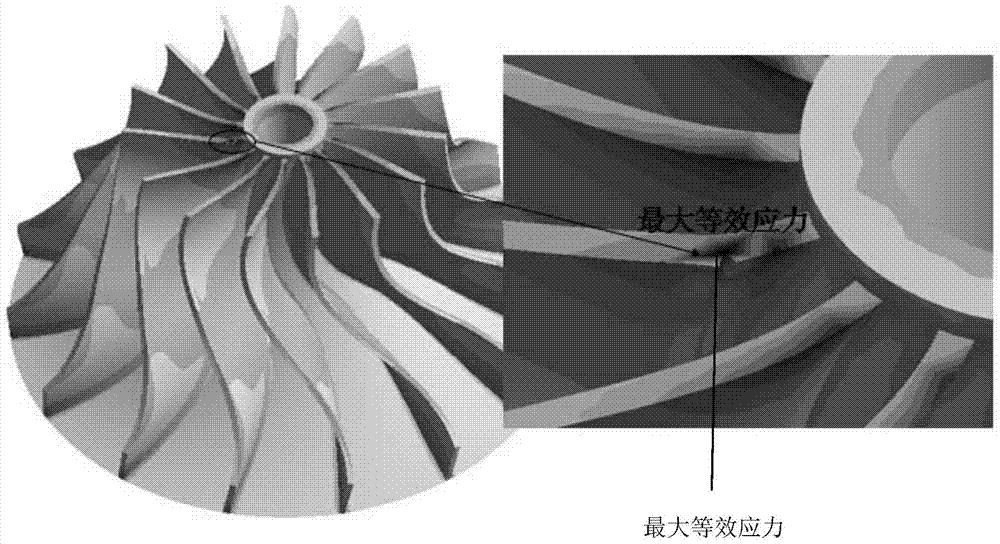

[0034] The present invention proposes a large-scale turboexpander impeller blade structure optimization design method considering defects, discusses the action mechanism of cracks on the impeller, determines the thickness of the blade section as the specific optimization object, and utilizes the multi-objective optimization algorithm based on genetic algorithm to optimize the blade section Thickness is specifically optimized, such as figure 1 , the method includes the following key steps:

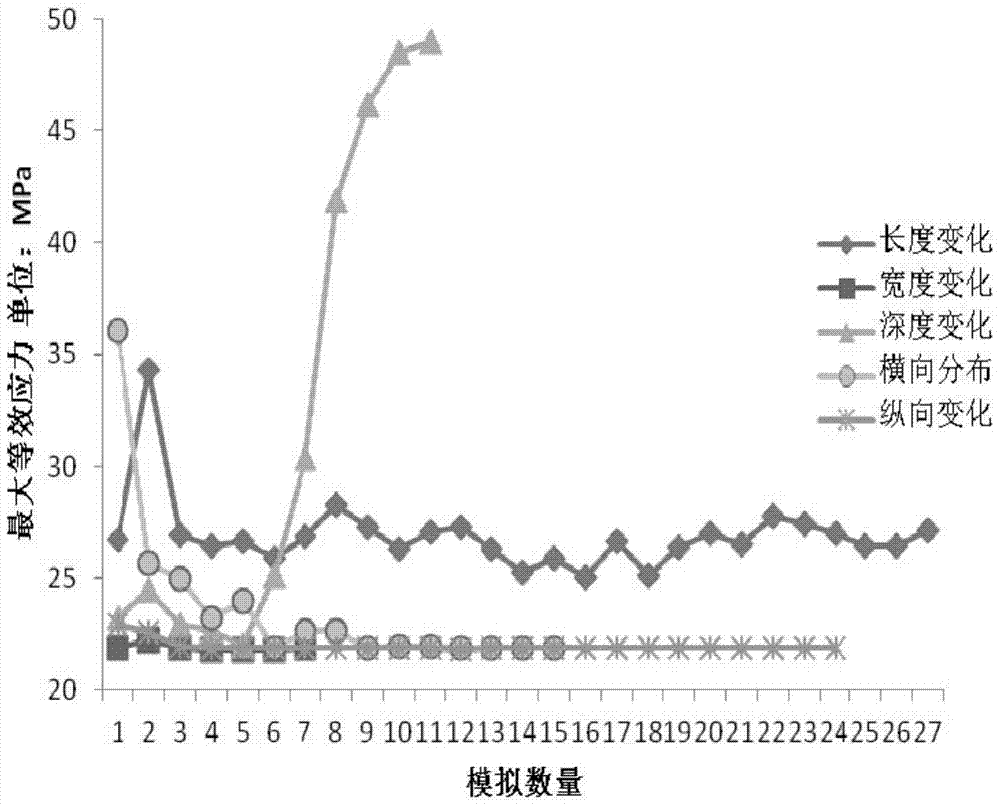

[0035]Step 1: Analyze the stress of different loads on the impeller model with defects to obtain the degree of influence of different loads on the cracks, which can be used as the force condition analysis for the impeller simplified crack parametric test. The main loads on the impeller include centrifugal load, thermal load and aerodynamic load. The thermal stress caused by the temperature effect is very small, and the stress intensity generated by it is less than 2% of the total stress in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com