Trace explosive and poison detector and using method thereof

A technology for detectors and explosives, applied in the field of trace explosives and drug detectors, can solve the problems of only one-time use, difficult recycling, gas detection, etc., and achieve the effect of low cost, super high sensitivity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0065] Example 1

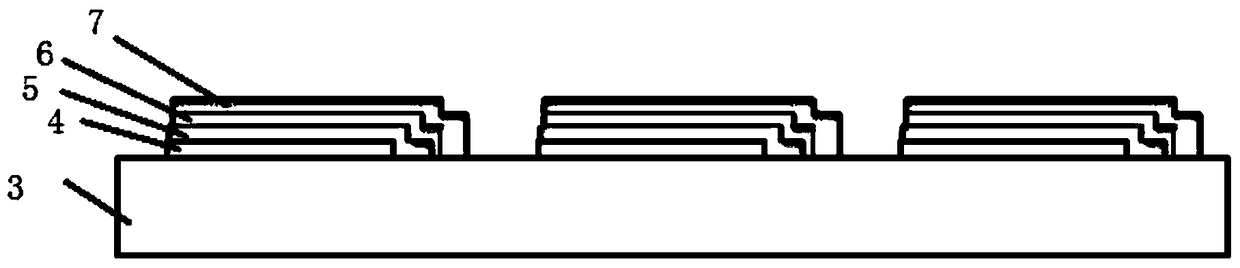

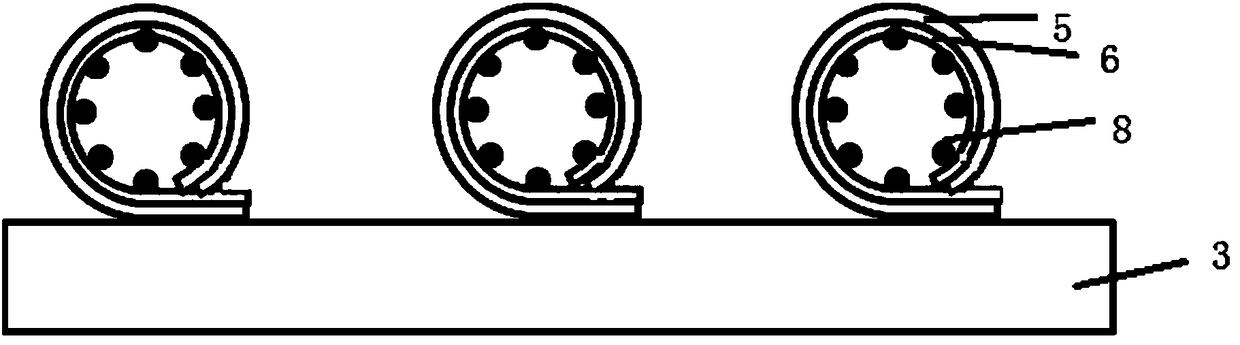

[0066] 1. Cleaning the substrate 3. Take a 2-inch silicon wafer, use acetone, ethanol, and deionized water for ultrasonic cleaning for ten minutes, and dry it in a nitrogen stream. figure 2 Shown.

[0067] 2. Lithography process. A layer of photoresist was spin-coated on the 3 sides of the substrate using the KW-5 type homogenizer of the Institute of Microelectronics of the Chinese Academy of Sciences, and the photoresist model used was AR-P3510T positive photoresist from Germany Allresist. The gluing process is to rotate at a low speed of 800 rpm for 10 seconds; then rotate at a high speed of 3000 rpm for 50 seconds. Remove the substrate, place it on a 120℃ electric hot plate and bake for 60 s. Take out the substrate 3, and use the MA6 UV lithography machine of German SUSS company to photoetch the substrate 3. The total size of the photoetching board is 5cm×5cm square array, and the photoetching plate material is a quartz glass plate coated with a square Cr ...

Example Embodiment

[0080] Example 2

[0081] 1. Cleaning the substrate 3. Take a 2-inch quartz wafer, wash it with acetone, ethanol, and deionized water sequentially for ten minutes, and dry it in a nitrogen stream.

[0082] 2. Lithography process. A layer of photoresist was spin-coated on the surface of the substrate 3 using the KW-5 type homogenizer of the Institute of Microelectronics of the Chinese Academy of Sciences, and the photoresist model used was AR-P3510T positive photoresist from Germany Allresist Company. The gluing process is to rotate at a low speed of 800 rpm for 10 seconds; then rotate at a high speed of 3000 rpm for 50 seconds. Remove the substrate 3, place it on a 120℃ electric hot plate and bake it for 60 s. Take out the substrate 3, and use the MA6 UV lithography machine of Suss Company in Germany to perform photoetching on the substrate 3. The total size of the photoetching board is 5cm×5cm square array, and the material of the photoetching board is a quartz glass plate coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com