Continuous zooming ultrasonic probe and zooming method adopted by same

A technology of ultrasonic probe and ultrasonic transducer, applied in ultrasonic/sonic/infrasonic diagnosis, ultrasonic/sonic/infrasonic Permian technology, ultrasonic/sonic/infrasonic image/data processing, etc. Micro-imaging system resolution and detection sensitivity, difficulty in obtaining lateral resolution and depth resolution, and difficulty in signal-to-noise ratio of non-zoom ultrasound probes, etc., to achieve the effects of promoting and applying, improving detection sensitivity, uniform image resolution and contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

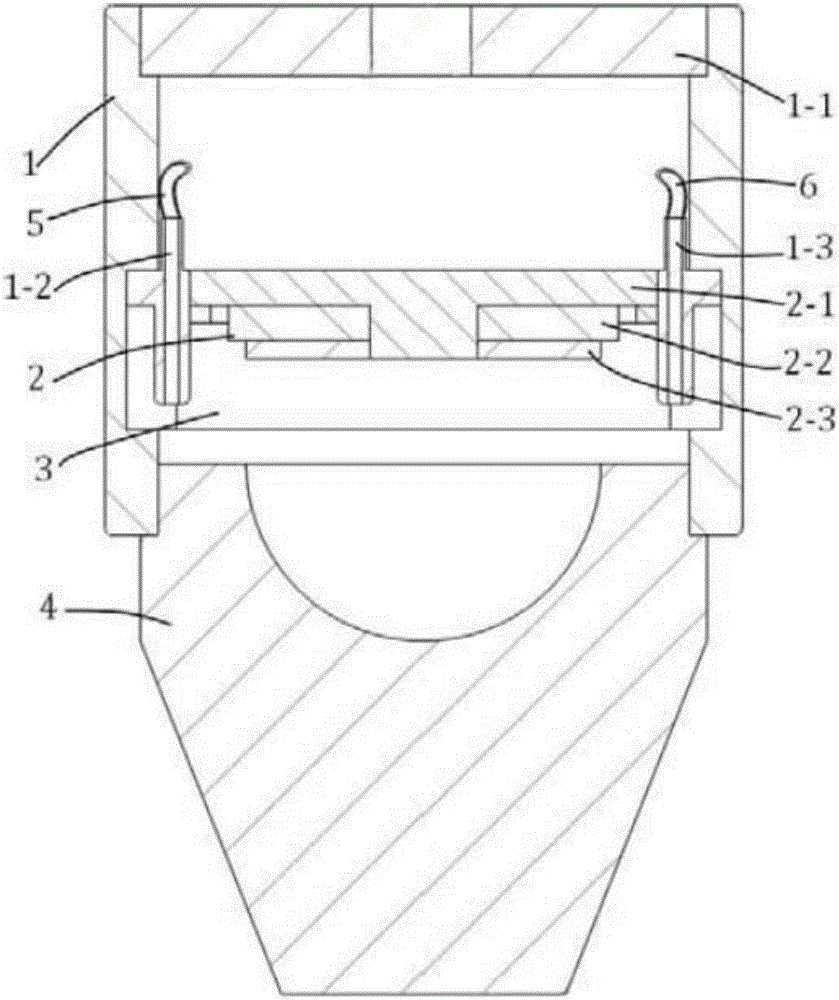

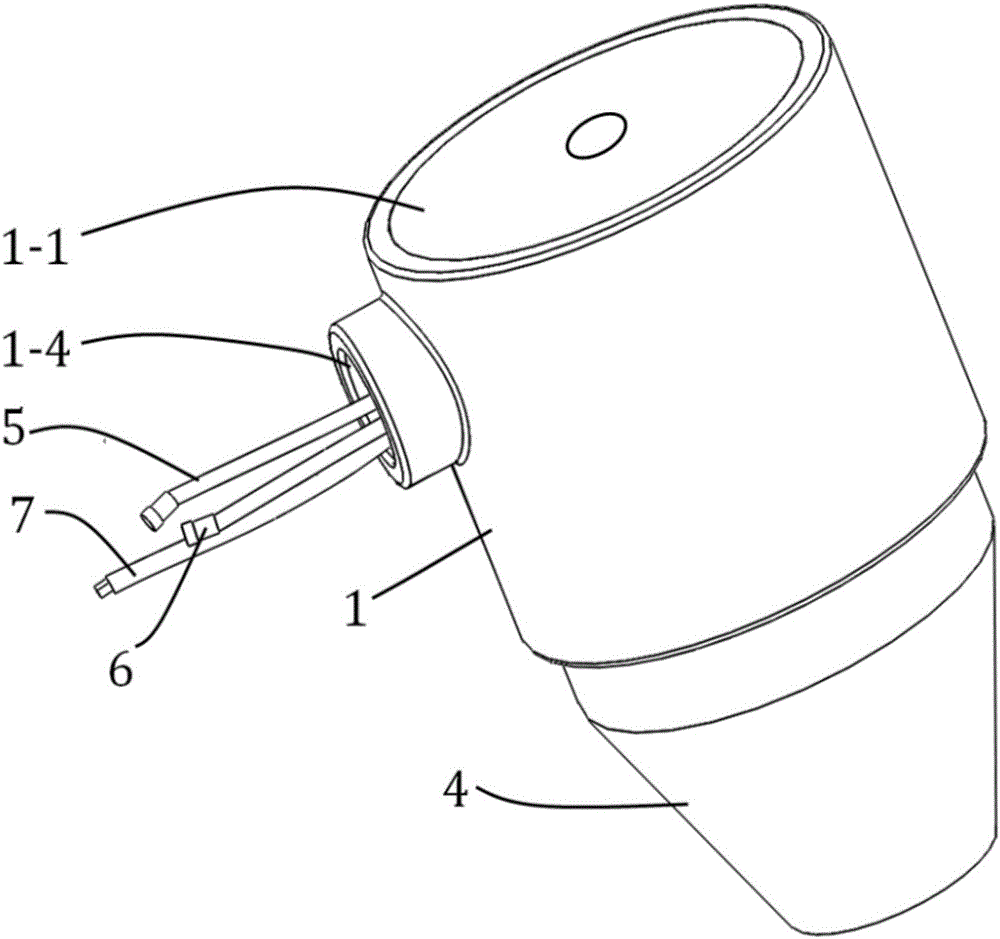

[0038] to combine figure 1 , figure 2 and Figure 10As shown, the annular ultrasonic transducer 2 includes a convex optical lens 2-1, an annular sound-absorbing plate 2-2, and an annular piezoelectric element 2-3, wherein the piezoelectric material of the annular piezoelectric element 2-3 is PVDF piezoelectric Electrode film with a thickness of 9 μm, adopts a ring structure with an outer diameter of 8 mm and an inner diameter of 3 mm, with a main frequency of 50 MHz, a bandwidth of 80%, and a sensitivity of -55 dB. The material of convex optical lens 2-1 adopts optical glass lens material, and convex optical lens is provided with boss, and the diameter of boss is 3mm, and light transmittance is excellent, and light transmittance is more than or equal to 98%. The light transmittance of the shaped optical lens is 98%. The material of the ring-shaped sound-absorbing panel 2-2 is glass fiber material, and its thickness ranges from 1 to 5mm (this embodiment uses 4mm), an outer ...

Embodiment 2

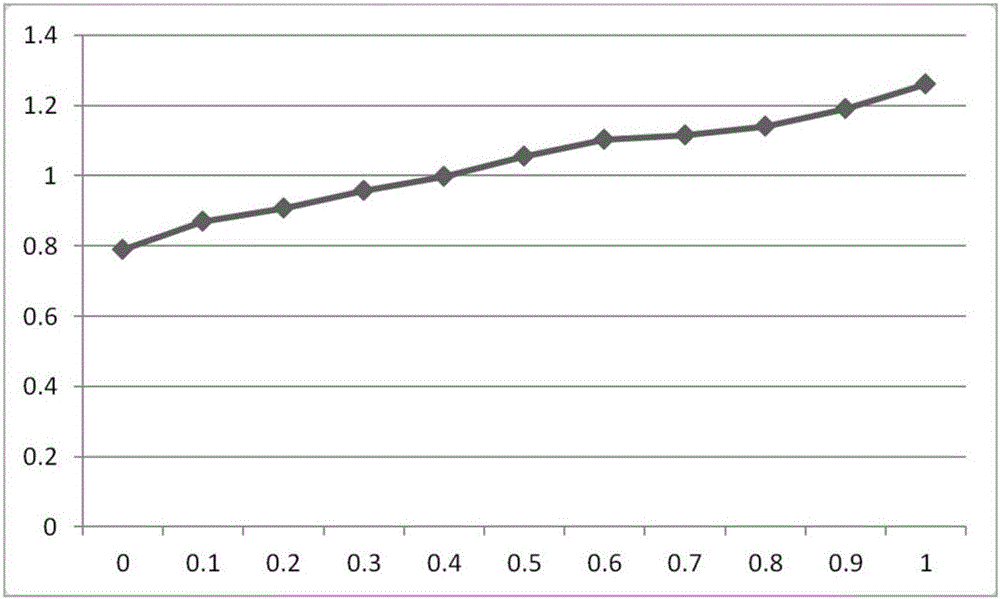

[0046] Using a photoacoustic microscope ultrasound probe in Example 1, its performance of transmitting and receiving signals was tested.

[0047] Olympus 5073PR ultrasonic transmitter receiver is used as the trigger signal source, its emission intensity is 12.5μJ, pulse repetition frequency is 5KHz; Taylor oscilloscope TDS2012B is used as the echo signal receiving; steel material plate is used as the test block, the thickness is 10MM, and the sound velocity is 5320m / s.

[0048] First connect the Olympus 5073PR ultrasonic transmitter receiver, Taylor oscilloscope TDS2012B, and the ultrasonic probe in Example 1, and place the Olympus 5073PR ultrasonic transmitter receiver in the transmitting and receiving state; secondly, apply an appropriate amount of couplant, use a syringe to inject the glycerin-ethanol mixture into the cavity 3 of the ultrasonic probe from the liquid inlet pipe 5 of the ultrasonic probe in Example 1 until the cavity 3 is filled, and there are no air bubbles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com